Phenolic epoxy powder coating for anticorrosion in seawater desalination pipeline, and preparation method thereof

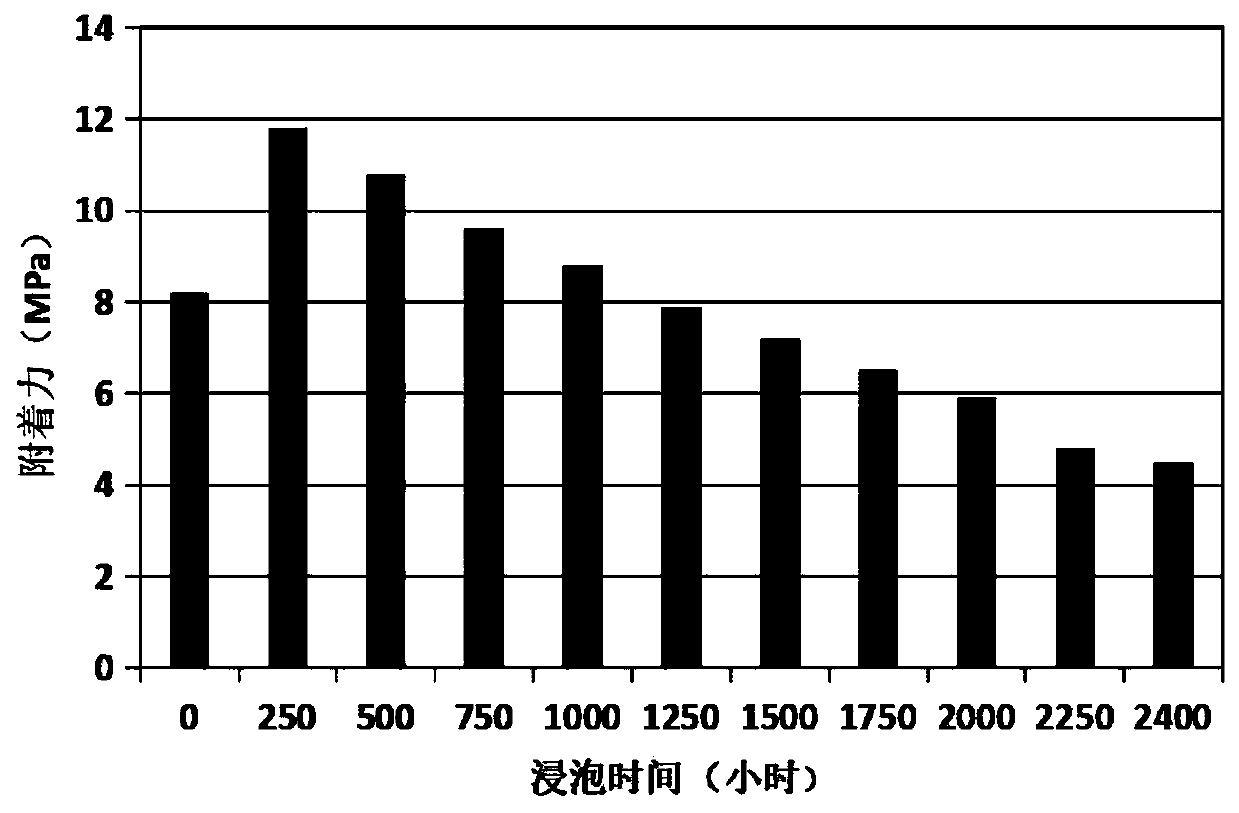

A phenolic epoxy powder and internal anti-corrosion technology, which is applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of shortening the service life of pipeline equipment, affecting anti-corrosion effects, and poor adhesion, and achieves excellent attachment Concentration, good resistance to seawater and salt spray, and the effect of dense paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A phenolic epoxy powder coating for anti-corrosion in seawater desalination pipelines, the phenolic epoxy coating is composed of A component and B component with a mass ratio of 5:1;

[0030] A component comprises the component of following mass parts:

[0031] 460g epoxy resin, 350g pigments and fillers, 90g additives, 90g solvent;

[0032] Wherein, the epoxy resin is made up of novolac epoxy resin, bisphenol A type epoxy resin and bisphenol F type epoxy resin with a mass ratio of 2:1:1;

[0033] B component comprises the component of following mass parts:

[0034] Amine curing agent 400g, solvent 20g, coupling agent 30g;

[0035] The amine curing agent is cashew nut shell oil modified phenalkamine.

[0036] Among them, the pigments and fillers are composed of anticorrosion pigments, coloring pigments and system fillers with a mass ratio of 0.8:1:2. The anticorrosion pigment is zinc phosphate, the colored pigment is a mixture of mica iron oxide and aluminum powder ...

Embodiment 2

[0045] A phenolic epoxy powder coating for anti-corrosion in seawater desalination pipelines, the phenolic epoxy coating is composed of A component and B component with a mass ratio of 5.8:1;

[0046] A component comprises the component of following mass parts:

[0047] 500g epoxy resin, 320g pigments and fillers, 30g additives, 50g solvent, 0.50g nano calcium carbonate;

[0048] Wherein, the epoxy resin is made up of novolac epoxy resin, bisphenol A type epoxy resin and bisphenol F type epoxy resin with a mass ratio of 2.8:1:1;

[0049] B component comprises the component of following mass parts:

[0050] Amine curing agent 600g, solvent 100g, coupling agent 23g;

[0051] The amine curing agent is cashew nut shell oil modified phenalkamine.

[0052] Among them, the pigments and fillers are composed of anticorrosion pigments, coloring pigments and system fillers with a mass ratio of 0.6:1:2. The anticorrosion pigment is aluminum tripolyphosphate, the colored pigment is mic...

Embodiment 3

[0061] A phenolic epoxy powder coating for anti-corrosion in seawater desalination pipelines, the phenolic epoxy coating is composed of A component and B component with a mass ratio of 6.4:1;

[0062] A component comprises the component of following mass parts:

[0063] 380g parts of epoxy resin, 240g parts of pigments and fillers, 120g parts of additives, 150g parts of solvent, 5g parts of nano calcium carbonate;

[0064] Wherein, the epoxy resin is made up of novolac epoxy resin, bisphenol A type epoxy resin and bisphenol F type epoxy resin with a mass ratio of 3.6:1:1;

[0065] B component comprises the component of following mass parts:

[0066] 510g parts of amine curing agent, 50g parts of solvent, 12g parts of coupling agent;

[0067] The amine curing agent is cashew nut shell oil modified phenalkamine.

[0068] Among them, the pigments and fillers are composed of anticorrosion pigments, coloring pigments and system fillers with a mass ratio of 0.66:1:2. The anticorro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com