Method for preparing two-dimensional black phosphorus crystals from white phosphorus as raw material

A technology of white phosphorus and black phosphorus, which is applied in the field of preparation of two-dimensional black phosphorus crystals, can solve the problems of high cost of reaction raw materials, high requirements for reaction equipment, and small crystal growth size, and optimize the heating program, reduce preparation costs, and reduce reaction time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

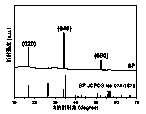

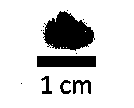

Embodiment 1

[0038] A method for preparing two-dimensional black phosphorus crystals using white phosphorus as a raw material, the specific preparation steps are as follows:

[0039] 1) Under an inert atmosphere, weigh 300 mg of white phosphorus, 12 mg of metal elemental tin and 6 mg of mineralizer tin tetraiodide at the bottom of a single-head sealed quartz tube, and seal the opening with a parafilm for later use;

[0040] 2) Remove the sealing film, and quickly use the vacuum sealing system to seal the reaction raw materials inside the vacuum quartz tube;

[0041] 3) Put the sealed quartz tube in the muffle furnace, and set a certain heating and cooling program to heat the quartz tube. After the reaction is completed, a large-volume, high-purity, high-quality two-dimensional black is finally produced. Phosphorus crystals.

[0042] 4) Put the sealed quartz tube in the muffle furnace. At room temperature, the temperature rises to 500°C for 1 hour, and then keeps it for 2 hours; , then co...

Embodiment 2

[0045] A method for preparing two-dimensional black phosphorus crystals using white phosphorus as a raw material, the specific preparation steps are as follows:

[0046] 1) Under an inert atmosphere, weigh 300 mg of white phosphorus, 24 mg of metal elemental tin and 12 mg of mineralizer tin tetraiodide at the bottom of a single-head sealed quartz tube, and seal the opening with a parafilm for later use;

[0047] 2) Remove the sealing film, and quickly use the vacuum sealing system to seal the reaction raw materials inside the vacuum quartz tube;

[0048] 3) Put the sealed quartz tube in the muffle furnace, and set a certain heating and cooling program to heat the quartz tube. After the reaction is completed, a large-volume, high-purity, high-quality two-dimensional black is finally produced. Phosphorus crystals.

[0049] 4) Put the sealed quartz tube in the muffle furnace. At room temperature, the temperature rises to 500°C for 1 hour, and then keeps it for 2 hours; , then c...

Embodiment 3

[0052] A method for preparing two-dimensional black phosphorus crystals using white phosphorus as a raw material, the specific preparation steps are as follows:

[0053] 1) Under an inert atmosphere, weigh 1200 mg of white phosphorus, 60 mg of metal elemental tin and 6 mg of mineralizer tin tetraiodide at the bottom of a single-head sealed quartz tube, and seal the opening with a parafilm for later use;

[0054] 2) Remove the sealing film, and quickly use the vacuum sealing system to seal the reaction raw materials inside the vacuum quartz tube;

[0055] 3) Put the sealed quartz tube in the muffle furnace, and set a certain heating and cooling program to heat the quartz tube. After the reaction is completed, a large-volume, high-purity, high-quality two-dimensional black is finally produced. Phosphorus crystals.

[0056] 4) Put the sealed quartz tube in the muffle furnace. At room temperature, the temperature rises to 480°C for 1 hour, and then keeps it for 2 hours; , then c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com