Microfluidic sample concentration device based on photo-thermal evaporation as well as application method

A concentration device and microfluidic technology, applied in the field of microfluidics, can solve problems such as difficult gas-liquid evaporation area, low efficiency of evaporation system, and reduced evaporation efficiency, so as to increase the evaporation area, solve the problem of uncontrollable free gas-liquid interface, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

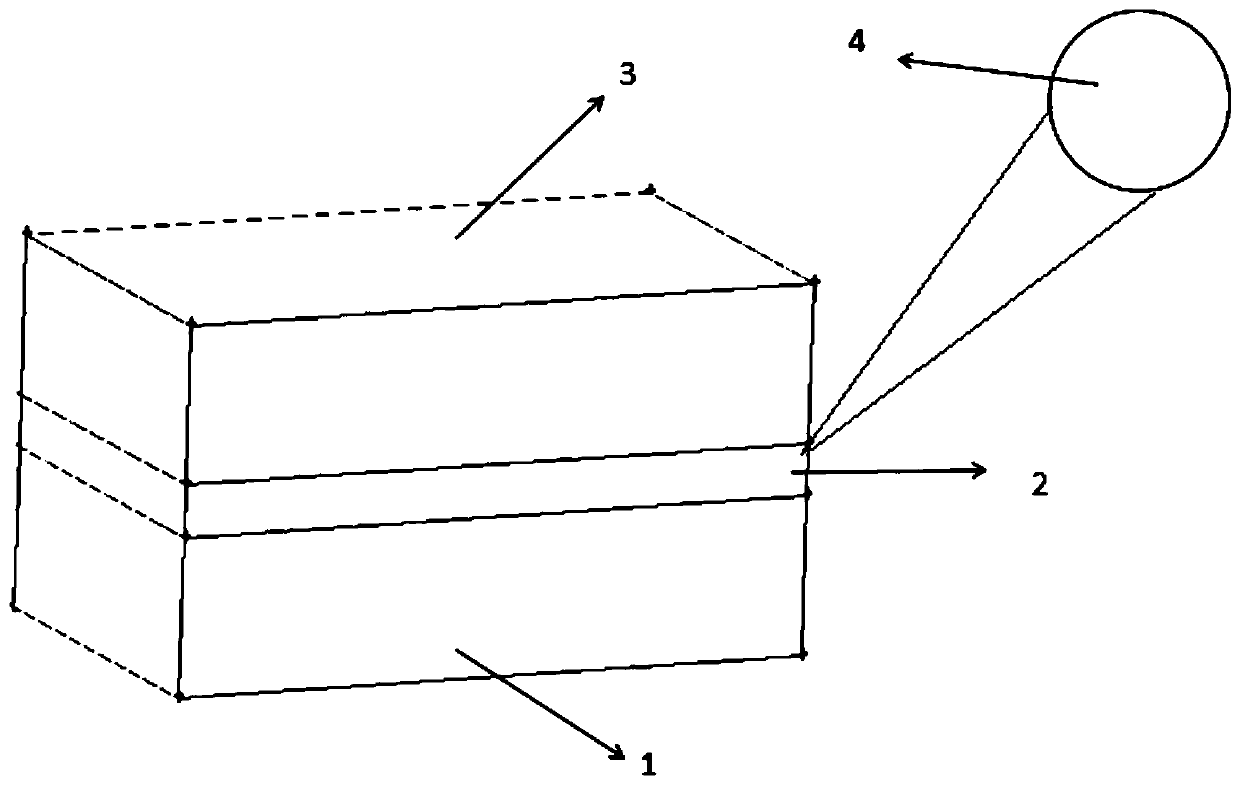

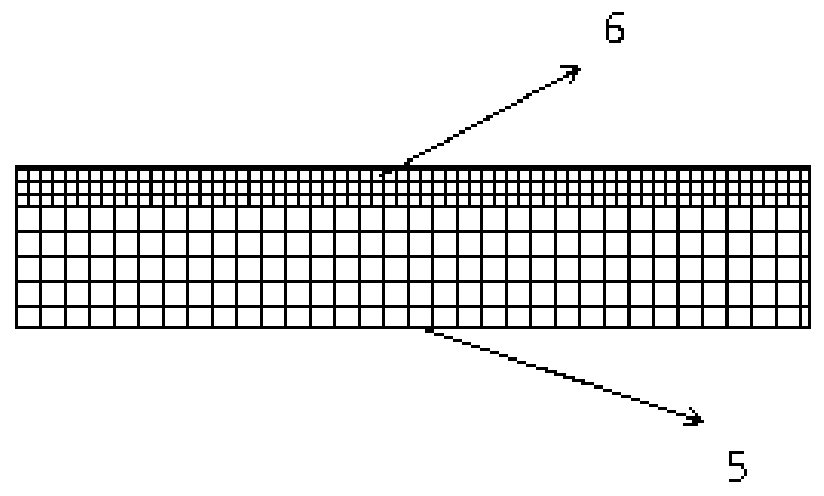

[0022] Example 1: see figure 1 with figure 2, a microfluidic sample concentration device based on photothermal evaporation, comprising a sample solution channel 1, that is, a substrate, a porous photothermal evaporation layer 2 is arranged above the sample solution channel 1, and a porous photothermal evaporation layer 2 is arranged above the porous photothermal evaporation layer 2 A carrier gas channel 3 is provided, and a light source 4 is provided on the outside of the porous photothermal evaporation layer 2; the porous photothermal evaporation layer 2 is composed of a hydrophilic porous photothermal medium layer 5 and a hydrophobic gas diffusion layer 6; the hydrophilic The water porous photothermal medium layer 5 generates capillary suction force on the liquid, so that the sample solution enters the hydrophilic porous photothermal medium layer 5. At the same time, the hydrophilic porous photothermal medium layer 5 absorbs the incident light of the light source 4 to gener...

Embodiment 2

[0028] Embodiment 2. The method of using a microfluidic sample concentration device based on photothermal evaporation, the concentration device includes a sample solution channel 1, a porous photothermal evaporation layer 2 is arranged above the sample solution channel 1, and the porous photothermal evaporation layer 2 is arranged above the sample solution channel 1. A carrier gas channel 3 is arranged above the evaporation layer 2, and a light source 4 is arranged outside the porous photothermal evaporation layer 2; the porous photothermal evaporation layer 2 is composed of a hydrophilic porous photothermal medium layer 5 and a hydrophobic gas diffusion layer 6 Composition; the hydrophobic gas diffusion layer 6 is a hydrophobic structure, located on the upper part of the hydrophilic porous photothermal medium layer 5; the carrier gas channel 3 has a gas microchannel structure, and the inlet of the gas microchannel is connected to the outlet of the purge gas storage device The ...

Embodiment 3

[0033] Embodiment 3: A microfluidic sample concentration device based on photothermal evaporation can be prepared as follows:

[0034] A. Processing of sample solution channel 1 and carrier gas channel 3: select two pieces of polydimethylsiloxane, rubber or resin elastic materials with the same shape and size as the matrix of sample solution channel 1 and carrier gas channel 3 respectively, through The soft lithography technique processes solution channels and gas microchannels on the substrate, respectively.

[0035] B, the making of porous photothermal evaporation layer 2:

[0036] B1. Evenly mix liquid phenol, calcium lignosulfonate, and sodium hydroxide at a mass ratio of 39.2:4.4:1, heat at a constant temperature of 80°C for 30 minutes, and then add 30% based on the mass ratio of 1:1.27 based on the mass of the mixture Formaldehyde aqueous solution was vacuum dehydrated at a temperature of 50° C. and a pressure of 0.1 MPa for 30 minutes to obtain a water-based phenolic r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com