Constant temperature and isopiestic pressure type thermal battery electric performance test system and test method thereof

An electrical performance testing, constant temperature and constant voltage technology, applied in primary battery use/maintenance, testing equipment, battery cooling/heating, etc. Disassemble and clean, improve test efficiency, and avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

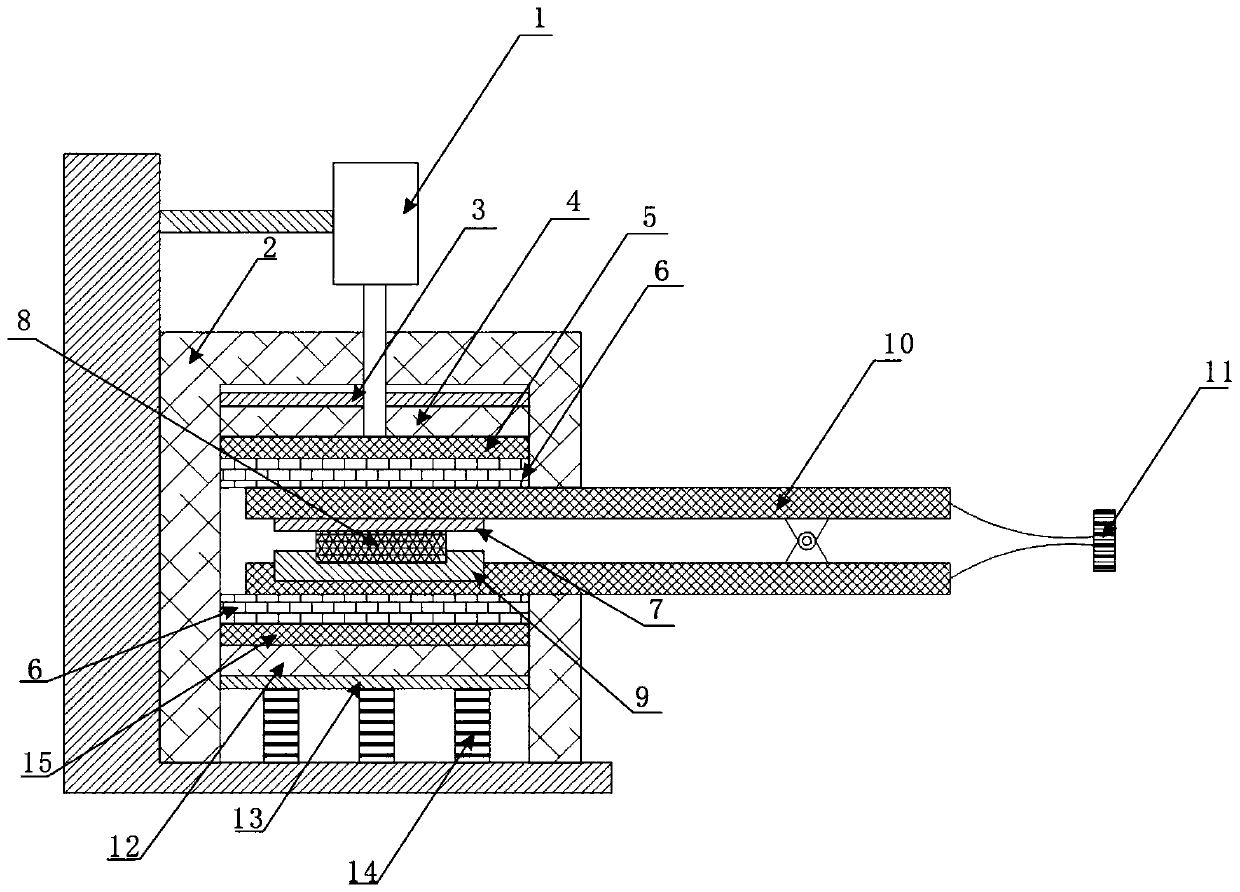

[0034] Such as figure 1 As shown, the constant temperature and constant pressure thermal battery electrical performance testing system includes an electrical performance testing system and a test device arranged in a glove box. The electrical performance testing system is preferably an Arbin BT-ML discharge device, and its voltage range is 0V- 40V, voltage test accuracy is + / -0.05% FSR (full scale); current range is 0A-30A, current test accuracy is + / -0.05% FSR (full scale).

[0035] Such as figure 1 As shown, the test device includes a holding furnace body 2, and a constant temperature and constant pressure system is arranged in the holding furnace body 2. Press machine 1, preferably press machine 1 is an electric press machine.

[0036] Such as figure 1 As shown, the constant temperature and constant pressure system includes a first heating hob 5 and a second heating hob 15 arranged in the holding furnace body 2 with a gap, wherein the first heating hob 5 is slidably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com