A constant temperature and constant pressure thermal battery electrical performance testing system and testing method thereof

An electrical performance testing, constant temperature and constant voltage technology, applied in primary battery use/maintenance, testing equipment, anti-corrosion/storage batteries, etc., can solve the problems of long mold replacement cycle, long activation time, test result deviation, etc., to improve the test Efficiency, easy disassembly and cleaning, improved consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

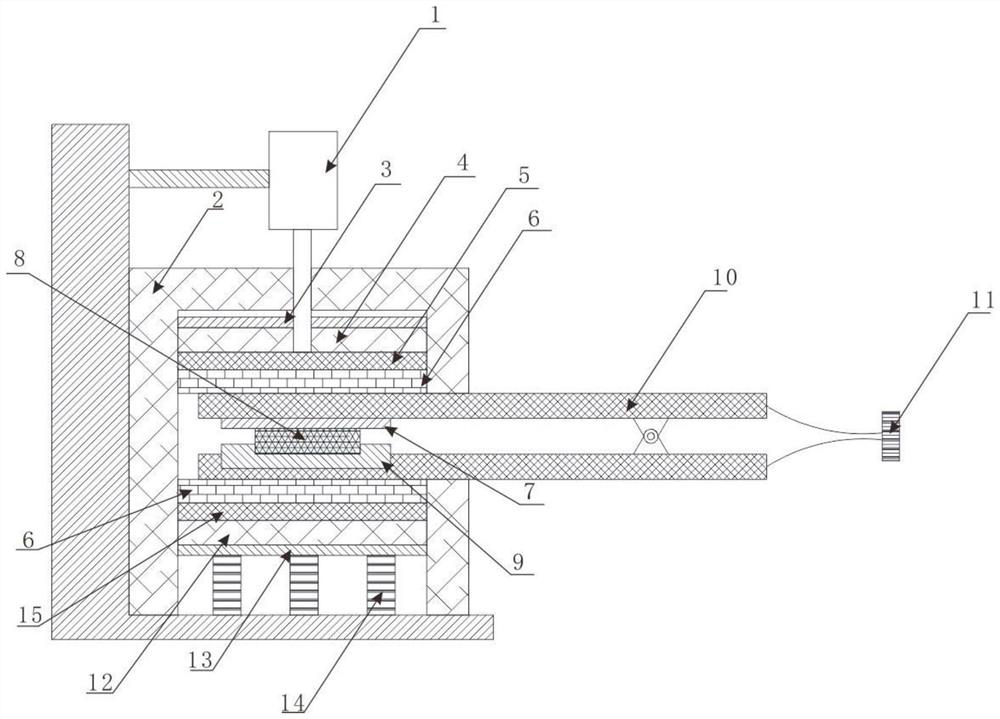

[0034] like figure 1 As shown, the constant temperature and constant pressure thermal battery electrical performance testing system includes an electrical performance testing system and a test device arranged in a glove box. The electrical performance testing system is preferably an Arbin BT-ML discharge device, and its voltage range is 0V- 40V, voltage test accuracy is + / -0.05% FSR (full scale); current range is 0A-30A, current test accuracy is + / -0.05% FSR (full scale).

[0035] like figure 1 As shown, the test device includes a holding furnace body 2, and a constant temperature and constant pressure system is arranged in the holding furnace body 2. Press machine 1, preferably press machine 1 is an electric press machine.

[0036] like figure 1 As shown, the constant temperature and constant pressure system includes a first heating hob 5 and a second heating hob 15 arranged in the holding furnace body 2 with a gap, wherein the first heating hob 5 is slidably arranged on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com