Synthetic technology of polyhexamethylene biguanide hydrochloride

A technology of polyhexamethylene biguanide hydrochloride and synthesis process, which is applied to the addition of paper forming aids, the addition of non-polymeric organic compounds, and the addition of anti-biological reagents, etc., can solve the problem of high viscosity of the reaction system and easy burning of the stirring motor , low conversion rate of raw materials, etc., to achieve the effect of large degree of product polymerization, excellent broad-spectrum antibacterial activity, high molecular weight and cationic degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

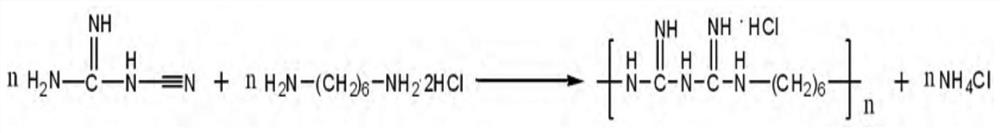

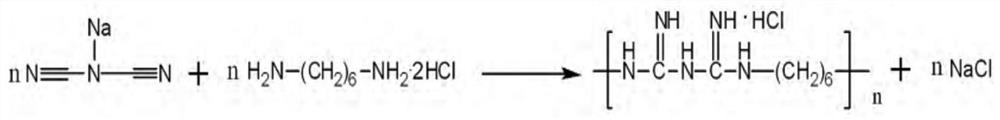

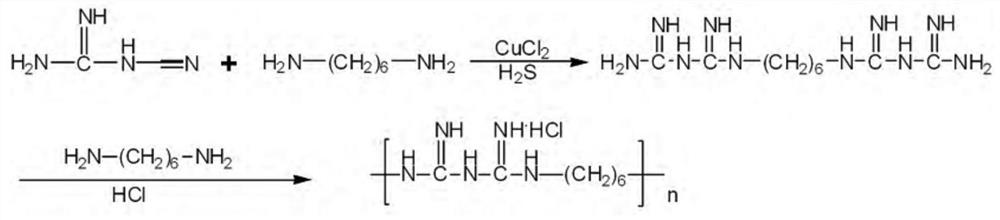

Method used

Image

Examples

Embodiment 1

[0049] The synthetic technique of polyhexamethylene biguanide hydrochloride comprises the following steps:

[0050] (1) 1,6-dicyanoguanidine hydrochloride and hexamethylenediamine hydrochloride are dissolved in an organic solvent, and an addition reaction occurs at 100° C., the 1,6-biscyanoguanidine and The mol ratio of described hexamethylenediamine hydrochloride is 1: 1.05, and described organic solvent is diethylene glycol, and the consumption of described organic solvent is 3 times of 1,6-dicyanoguanidine hexane mass, so Described catalyst is 2-bromo-2-methylisobutylsiloxysilsesquioxane, and the consumption of described catalyst is 0.5 times of 1,6-dicyanoguanidine mass;

[0051] (2) After the addition reaction occurs, polyhexamethylene biguanide hydrochloride is obtained by performing self-condensation reaction at 150-160° C. under the action of a catalyst.

[0052] The polyhexamethylene biguanide hydrochloride synthesized in this example has confirmed the correctness of...

Embodiment 2

[0055] () Dissolve 1,6-dicyanoguanidine hydrochloride and hexamethylenediamine hydrochloride in an organic solvent, and an addition reaction occurs at 120° C., the 1,6-dicyanoguanidine and the The mol ratio of described hexamethylenediamine hydrochloride is 1: 1.07, and described organic solvent is diethylene glycol, and the consumption of described organic solvent is 4 times of 1,6-dicyanoguanidine hexane quality, and described The catalyst is azodiisopropylimidazoline hydrochloride, and the amount of the catalyst is 1 times the quality of 1,6-dicyanoguanidine;

[0056] (2) After the addition reaction occurs, polyhexamethylene biguanide hydrochloride is obtained by performing self-condensation reaction at 150-160° C. under the action of a catalyst.

[0057] The polyhexamethylene biguanide hydrochloride synthesized in this example has confirmed the correctness of the target product and the quality of the product through NMR and high-performance liquid chromatography detection ...

Embodiment 3

[0060] (1) Dissolve 1,6-dicyanoguanidine hexane and hexamethylenediamine hydrochloride in an organic solvent, and an addition reaction occurs at 130° C., the 1.6-dicyanoguanidine hexane and the The mol ratio of hexamethylenediamine hydrochloride is 1: 1.1, and described organic solvent is diethylene glycol, and the consumption of described organic solvent is 6 times of 1,6-dicyanoguanidine hexane quality, and described catalyst It is 2-bromo-2-methylisobutylsiloxysilsesquioxane, and the amount of the catalyst is 1.5 times the mass of 1,6-dicyanoguanidinohexane;

[0061] (2) After the addition reaction occurs, polyhexamethylene biguanide hydrochloride is obtained by performing self-condensation reaction at 150-160° C. under the action of a catalyst.

[0062] The polyhexamethylene biguanide hydrochloride synthesized in this example has confirmed the correctness of the target product and the quality of the product through NMR and high-performance liquid chromatography detection t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com