Steel structure anti-corrosion coating

A technology for anti-corrosion coatings and steel structures, applied in the direction of anti-corrosion coatings, anti-fouling/underwater coatings, epoxy resin coatings, etc., can solve the problems of poor coating durability, high VOC emissions, poor comprehensive anti-corrosion performance, etc., to achieve enhanced Light effect, sufficient contact area, avoid delamination effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

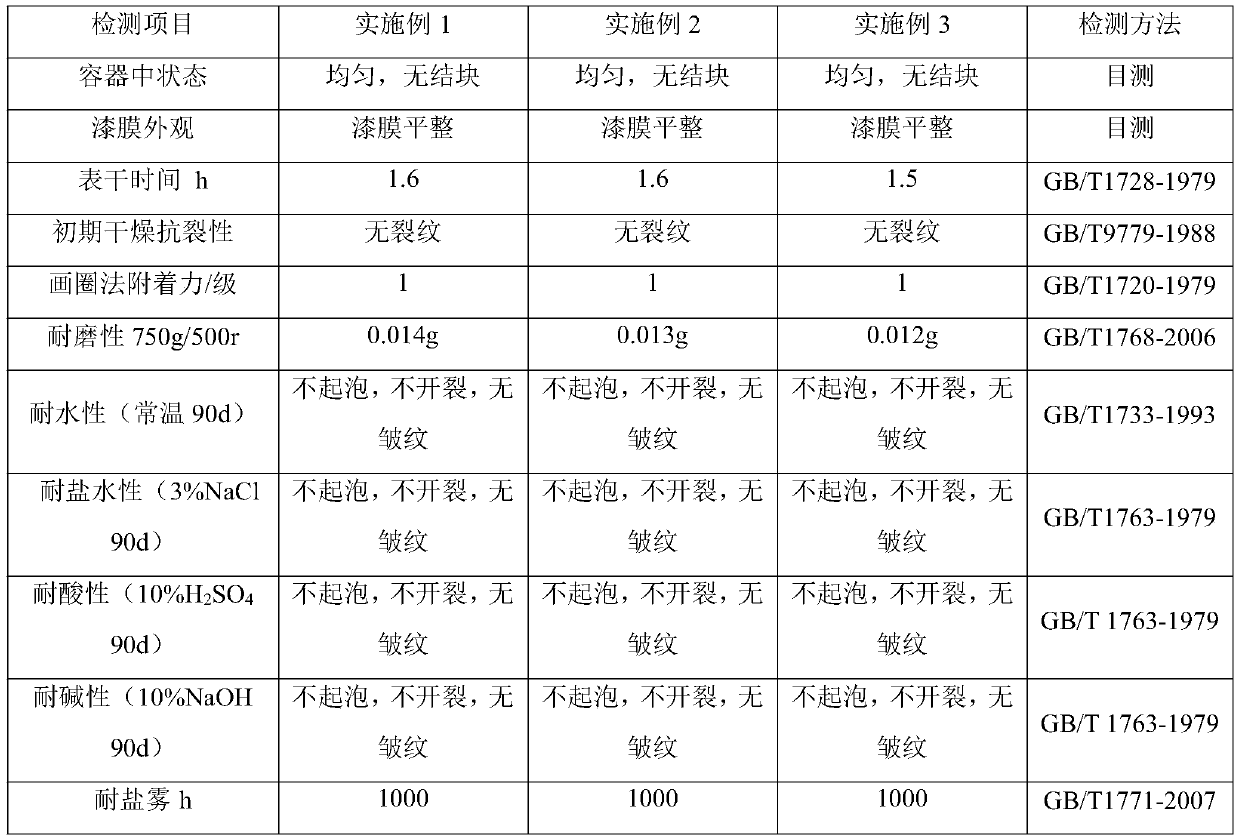

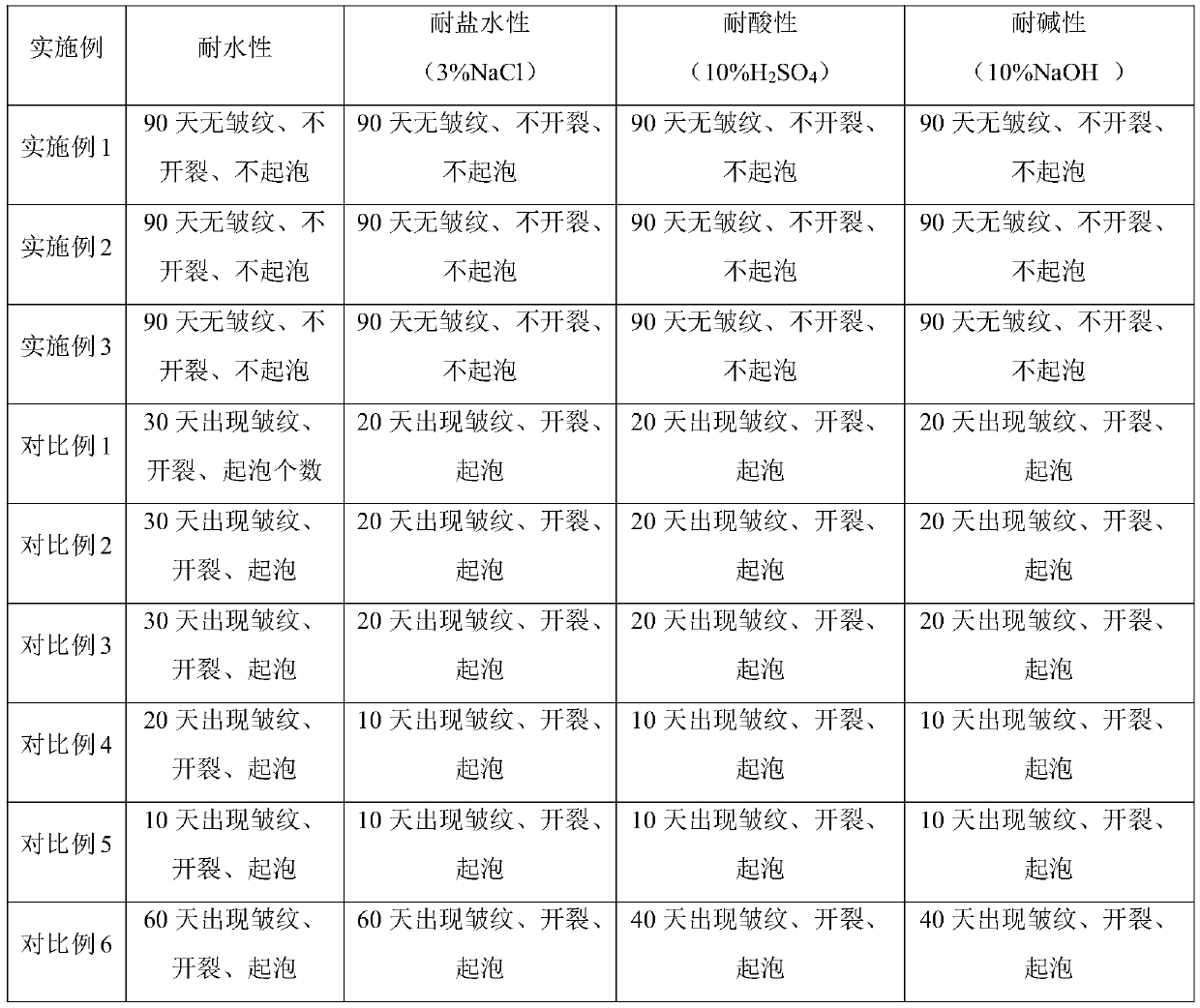

Embodiment 1

[0038] An anti-corrosion coating for steel structures, which is prepared by mixing component A and component B at a weight ratio of 5:2, wherein component A is composed of the following raw materials in parts by weight: 25 parts of epoxy resin mixture, 15 parts Composite nanopowder, 5 parts of modified graphene oxide, 5 parts of filler, 5 parts of dispersant, 0.4 part of wetting agent, 0.8 part of thickener and 0.2 part of anti-sedimentation agent;

[0039] Epoxy resin mixture is the mixture that E44 epoxy resin and E12 epoxy resin weight ratio are 1: 1;

[0040] Component B consists of ketimine and aluminum chloride in a weight ratio of 3:1;

[0041] The preparation method of steel structure anticorrosion paint specifically comprises the following steps:

[0042] (1) Mix the epoxy resin and deionized water in said parts by weight under stirring conditions, preheat at 80°C for 20min, lower the temperature to normal temperature to form an epoxy resin emulsion;

[0043] (2) Di...

Embodiment 2

[0050] An anti-corrosion coating for steel structures, which is prepared by mixing component A and component B at a weight ratio of 5:2, wherein component A is composed of the following raw materials in parts by weight: 40 parts of epoxy resin mixture, 17.5 parts Composite nanopowder, 7.5 parts of modified graphene oxide, 11.5 parts of filler, 7.5 parts of dispersant, 0.5 part of wetting agent, 1.0 part of thickener and 0.25 part of anti-settling agent;

[0051] Epoxy resin mixture is the mixture that E44 epoxy resin and E12 epoxy resin weight ratio are 1: 1;

[0052] Component B consists of ketimine and aluminum chloride in a weight ratio of 4:1;

[0053] The preparation of steel structure anticorrosion coating specifically comprises the following steps:

[0054] (1) Mix the epoxy resin and deionized water in said parts by weight under agitation, preheat at 90°C for 15 minutes, and lower the temperature to normal temperature to form an epoxy resin emulsion;

[0055] (2) Dis...

Embodiment 3

[0062] An anti-corrosion paint for steel structures is prepared by mixing component A and component B at a weight ratio of 5:2, wherein component A is composed of the following raw materials in parts by weight: 55 parts of epoxy resin mixture, 20 parts Composite nanopowder, 10 parts of modified graphene oxide, 18 parts of filler, 10 parts of dispersant, 0.6 part of wetting agent, 1.2 parts of thickener and 0.3 part of anti-sedimentation agent;

[0063] Epoxy resin mixture is the mixture that E44 epoxy resin and E12 epoxy resin weight ratio are 1: 1;

[0064] Component B consists of ketimine and aluminum chloride in a weight ratio of 5:1;

[0065] The preparation of steel structure anticorrosion coating specifically comprises the following steps:

[0066] (1) Mix the epoxy resin and deionized water in said parts by weight under agitation, preheat at 100°C for 10 minutes, and lower the temperature to normal temperature to form an epoxy resin emulsion;

[0067] (2) Dispersing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com