Salt-resistant Gemini amphoteric ion viscoelastic surfactant and preparation method of high salinity water-based cleaning fracturing fluid

A surfactant and clean fracturing fluid technology, applied in the preparation of sulfonate, chemical instruments and methods, preparation of sulfonic acid, etc., can solve problems such as non-resistance to salinity, and achieve good salt resistance and good viscoelasticity , the effect of strong surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The method of synthesizing the salt-tolerant type gemini zwitterionic viscoelastic surfactant with erucamide propyl dimethylamine of the present embodiment is as follows:

[0050] Epichlorohydrin and taurine are obtained by reacting at 40°C for 6 hours in a mixture of water and ethanol at a molar ratio of 2:1. Then, the molar ratio of erucamide propyl dimethylamine and the intermediate is (2-2.5): 1, and the mixed solution of water and ethanol is used as the solvent. Hour. Evaporate the solvent at 80°C on a rotary evaporator, dissolve the crude product with ethyl acetate at 40°C, and then recrystallize the ethyl acetate solution at 5°C to remove unreacted erucamide propyl dimethyl amine to obtain a crystalline product; the crystalline product was treated by rotary evaporation to remove ethyl acetate to obtain a pure salt-tolerant gemini zwitterionic viscoelastic surfactant.

Embodiment 2

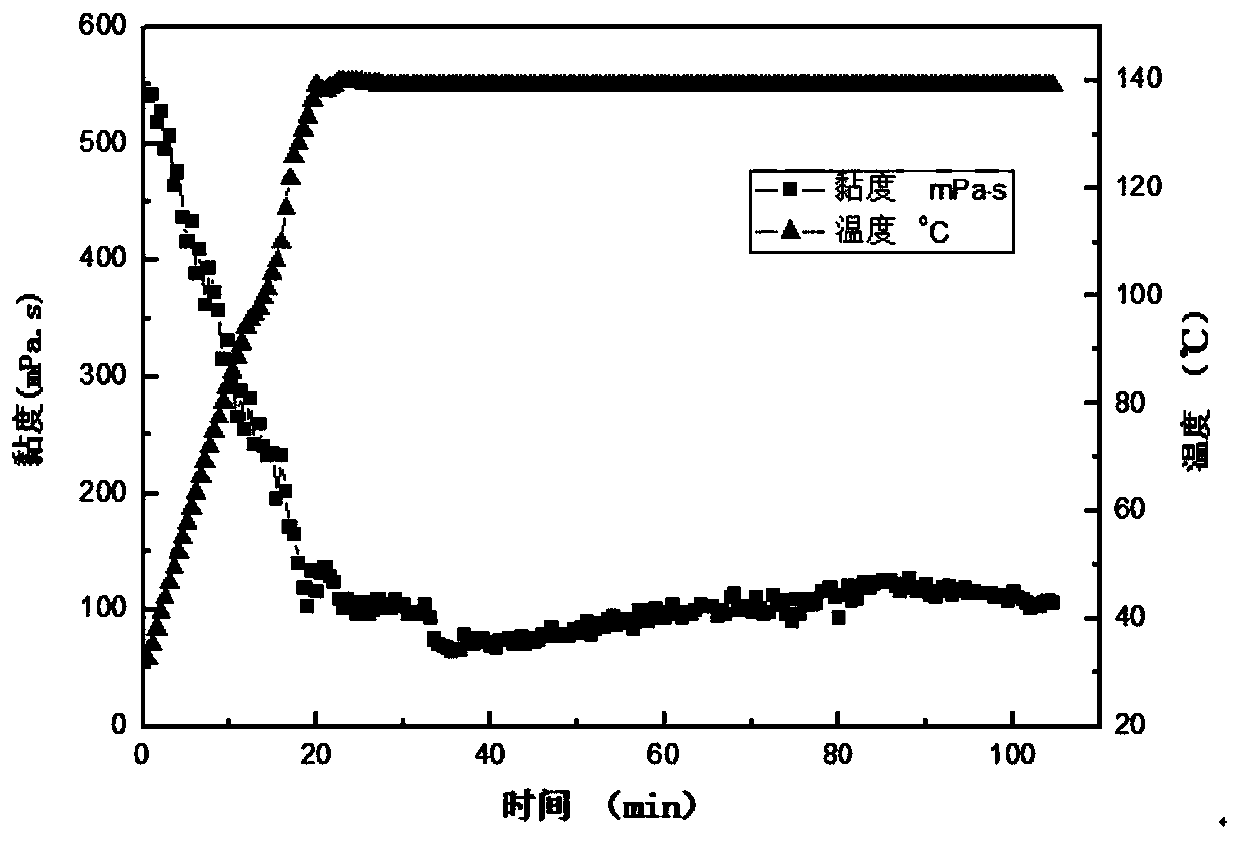

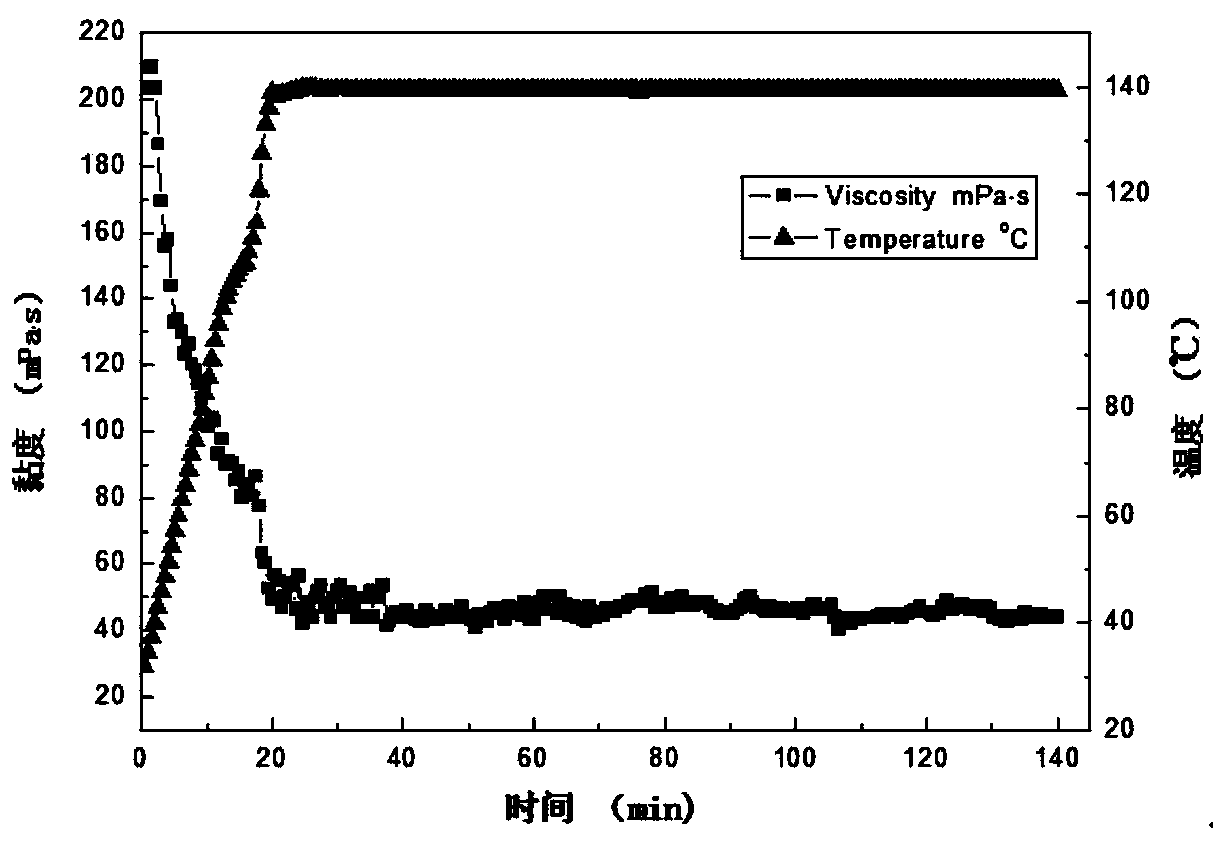

[0052] Take the viscoelastic surfactant in Example 1, use the 3wt% seawater-based clean fracturing fluid prepared by South China Sea seawater in Table 1, at 140°C, 170s -1 Under the condition of shearing for about 2 hours, the apparent viscosity is still above 50mPa.s, which meets the requirements of the industry standard SY / T6376-2008.

Embodiment 3

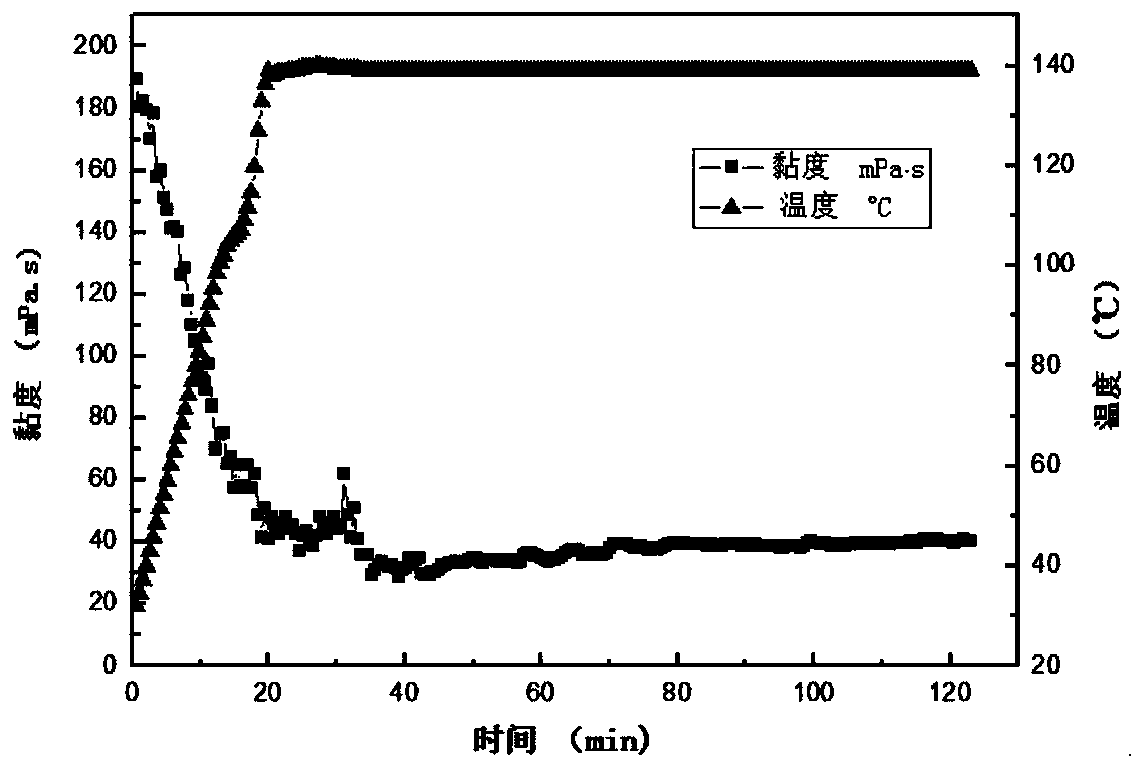

[0054] Get the viscoelastic surfactant in Example 1, use the 3wt% seawater-based clean fracturing fluid prepared by the Gulf of Mexico seawater in Table 1, at 140 ° C, 170s -1 Under the condition of shearing for about 2 hours, the apparent viscosity is still above 40mPa.s, which meets the requirements of the industry standard SY / T6376-2008.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

| Apparent viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com