Acetonitrile double-effect pressure-swing refining separation system

A separation system, acetonitrile technology, applied in the direction of carboxylic acid nitrile purification/separation, organic chemistry, etc., can solve the problems of low energy utilization efficiency, energy consumption, environment, resource utilization, etc. The effect of process investment cost, energy consumption reduction and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

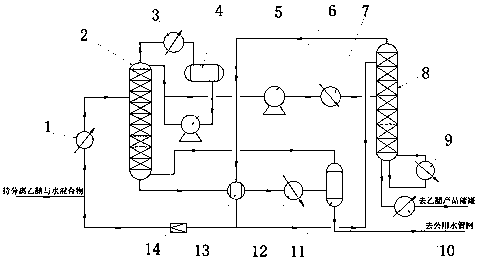

[0018] A kind of acetonitrile double-effect pressure swing refining separation system is further described below with reference to the accompanying drawings:

[0019] figure 1 The structure schematic diagram of the present invention is given, because the traditional acetonitrile refining and separation system has a large pressure and temperature difference between the atmospheric column and the high-pressure column, and the coupling efficiency between the two columns is relatively poor. The consumption of cold and hot public works is relatively large, the low-concentration wastewater has not been effectively concentrated, the wastewater treatment load of the system is large, the process operation is difficult, the operation cost is high, and the equipment investment cost is high, which does not meet the requirements of high efficiency and green , The concept of environmental protection production.

[0020] So the setting of the present invention has included atmospheric tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com