Method for preparing porous boron-doped diamond electrodes using nano-diamond powder as a pseudo-template

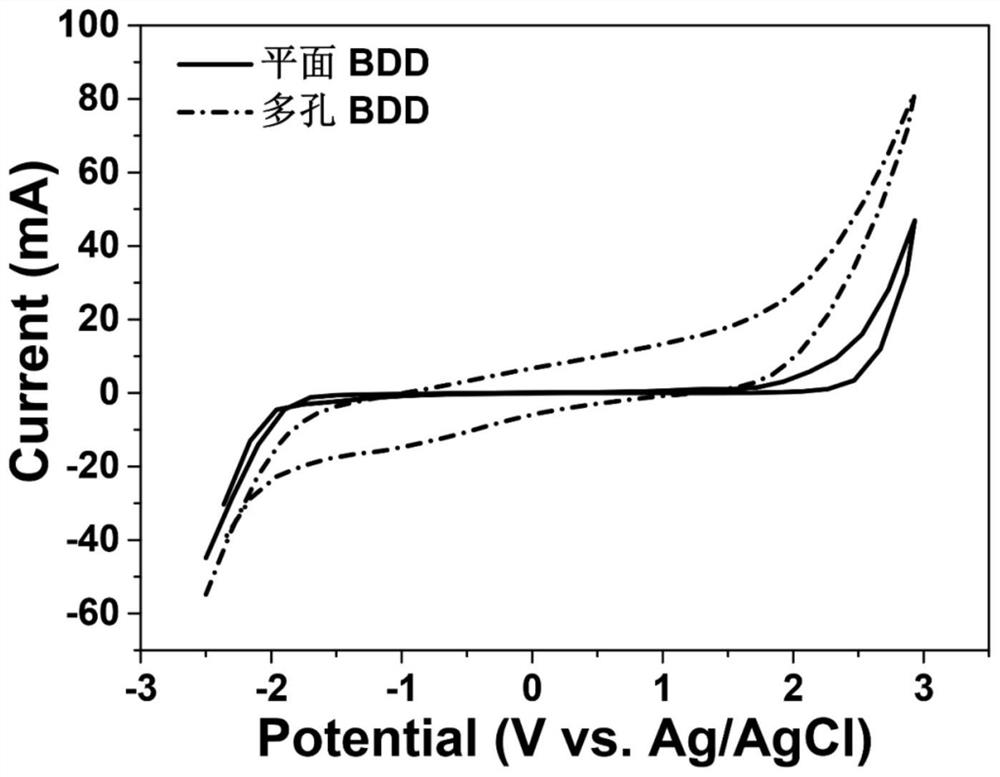

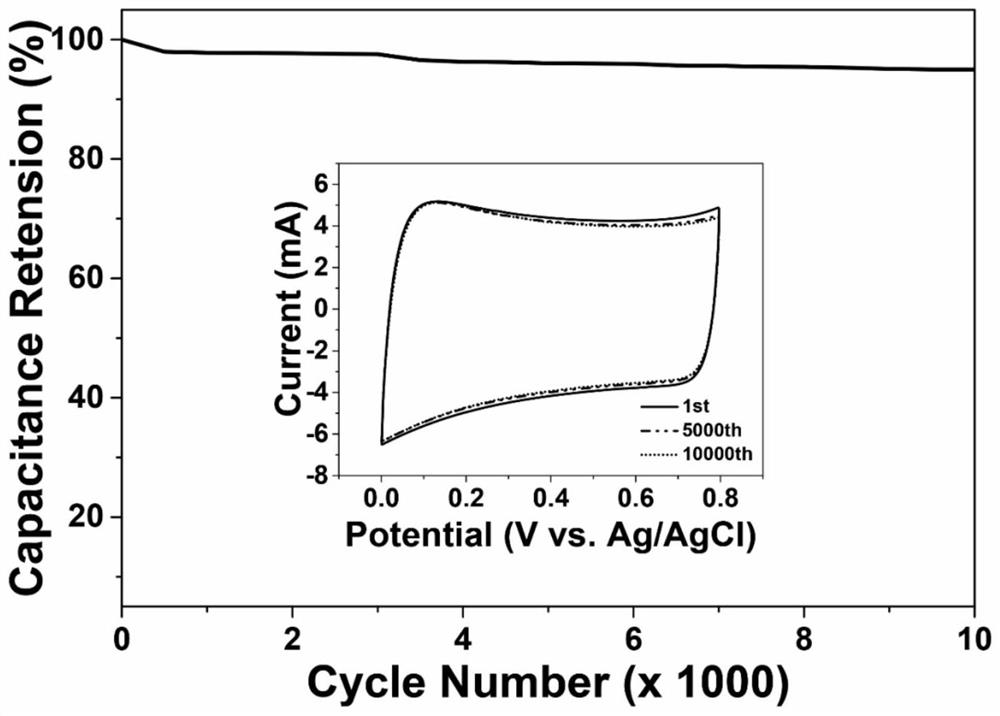

A technology of nano-diamond powder and boron-doped diamond, which is applied in the direction of metal material coating process, coating, gaseous chemical plating, etc., can solve the problems of high time-consuming cost, complex three-dimensional BDD electrode process, etc., and achieve large chemical double-electrode Layer capacitance, improved repeatability, improved energy density and power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] a. Select a negative surface potential, 5 to 10 nm particle diameter nano diamond powder is placed in deionized water for 100 minutes, and a stable diamond flour suspension of 1 g / L is prepared, selecting 20 mm × 20 mm × 0.5mm sizes of silicon After the film, alcohol, deionized water, respectively, washed 15, 15, 10 min, respectively, was dried with nitrogen;

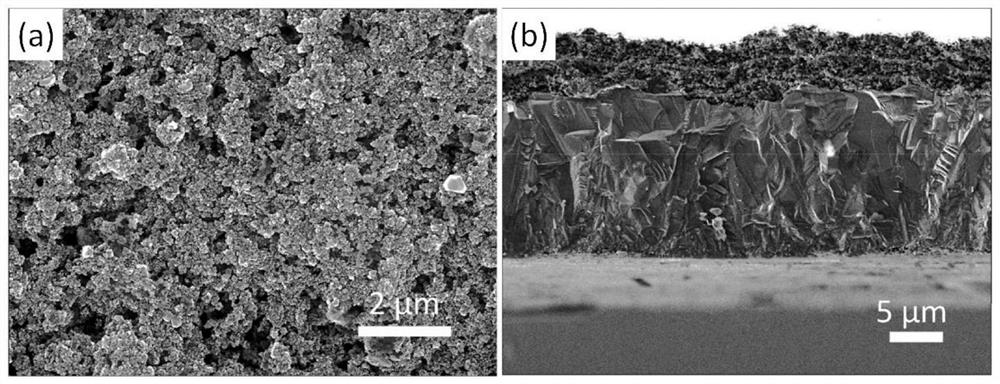

[0051] b. Drop the diamond suspension prepared by step A to the silicon substrate, form a uniform, continuous, flat suspension film, and then heat evaporated in the suspension, nano-diamonds by thermostat heat treatment by hot plate 60 ° C. The powder is self-assembled on the silicon substrate to form a layer of flat porous membrane;

[0052] c. Put the silicon substrate containing the nano-diamond porous porous film prepared in step B into a microwave plasma chemical vapor deposition chamber vacuum to 10 -3 After the PA, turn on the working gas to adjust the gas pressure, turn on the microwave power supply, adjust...

Embodiment 2

[0055] a. Choose a negative surface potential, 30 to 60 nm particle diameter nano diamond powder is placed in deionized water for 100 minutes, and the concentration is 1 g / L stable diamond flour suspension, select 20 mm × 20 mm × 0.5 mm sizes After the film, alcohol, deionized water, respectively, washed 15, 15, 10 min, respectively, was dried with nitrogen;

[0056] b. Drop the diamond suspension prepared by step A to the silicon substrate, form a uniform, continuous, flat suspension film, and then heat evaporated in the suspension, nano-diamonds by thermostat heat treatment by hot plate 60 ° C. The powder is self-assembled on the silicon substrate to form a layer of flat porous membrane;

[0057] c. Put the silicon substrate containing the nano-diamond porous porous film prepared in step B into a microwave plasma chemical vapor deposition chamber vacuum to 10 -3 After the PA, turn on the working gas to adjust the gas pressure, turn on the microwave power supply, adjust the mic...

Embodiment 3

[0060] a. Select a negative surface potential, 5 to 10 nm particle diameter nano diamond powder is placed in deionized water for 100 min, and the stable diamond flour suspension of 1 g / L is prepared, select 20 mm × 20 mm × 0.5mm specification The silicon wafer is made of acetone, alcohol, deionized water, respectively, washed 15, 15, 10 min, respectively, with nitrogen.

[0061] b. Diamond suspension prepared by step A is dropped onto the silicon substrate, form a uniform, continuous, flat suspension film, and then heat evaporated in the suspension, nano-diamonds by thermostatic temperature through hot plate 65 ° C. The powder is self-assembled on the silicon substrate to form a layer of flat porous membrane;

[0062] c. Put the silicon substrate containing the nano-diamond porous porous film prepared in step B into a microwave plasma chemical vapor deposition chamber vacuum to 10 -3 After the PA, turn on the working gas to adjust the gas pressure, turn on the microwave power su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com