Fresh-maintaining device and method for zizania latifolia

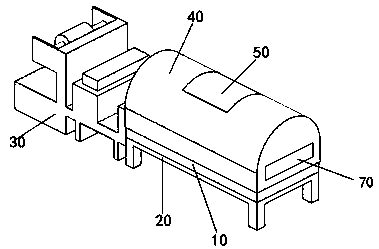

A processing equipment, water bamboo technology, which is used in the preservation of fruits/vegetables, fruit and vegetable preservation, and food preservation through radiation/electricity treatment, which can solve the problem that the freshness and flavor cannot meet the requirements of food safety and delicious flavor and pay attention to freshness preservation. The problem of poor effect, etc., can reduce the infection of disease microorganisms, maintain the texture, and reduce the decrease of the hardness of water bamboo.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] This embodiment provides a fresh-keeping treatment method for wild rice stems, specifically using fresh wild wild rice stems as a raw material, and performing the fresh-keeping treatment according to the following process:

[0051] Harvesting: When harvesting, the outer leaf sheaths of Zizania are retained, and the baskets are transported back to the product processing room within 3 hours after harvest, the inedible leaf sheaths are peeled off, and then the damage is removed, and the Zizania of the same size is screened as the primary product of Zizania;

[0052] Cleaning: transport the primary products of Zizania zizania along with the conveyor belt to the cold water clear water pool to clean the dust on the surface. The temperature of the cold water pool is 0-10°C, and the cleaning time is 1 to 5 minutes. 100-200ppm sodium hypochloride solution, immersion disinfection time 2-3min;

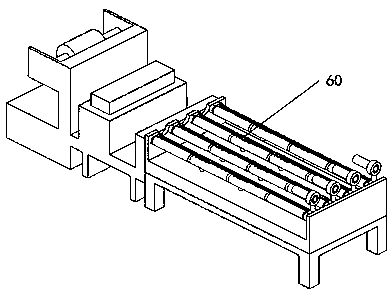

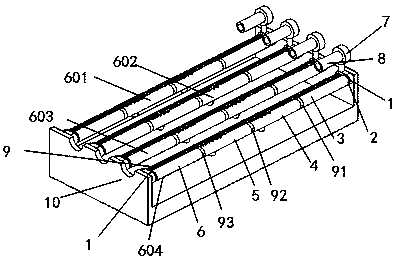

[0053] Heat Shock: The cleaned Zizania primary product is transported with the conveyo...

Embodiment 2

[0074] Harvest and select the inedible leaf sheath parts, remove the damage, and the same size of the first product of Zizania zizania; use the conveyor belt to transport the dust to the cold water pool to clean the surface dust, the temperature is less than 10°C, and the cleaning time is less than 5 minutes, and then the conveyor belt is transported to the disinfection pool To remove surface microorganisms, use 100-200ppm sodium hypochloride solution in the disinfection pool, soak for 2-3 minutes; then transport the hot water pool for heat shock treatment, keep the temperature at 50-54°C, and keep for 30 seconds to 2 minutes; The belt passes through the blower tunnel, and the water on the air-dried wild rice stem is exposed; the initial product is transported to the light treatment room along with the conveyor belt, and the cold plate is placed under the UV-C lamp. , control the irradiation dose to 4.30 KJ m -2 , the irradiation time is 8-10 minutes; the final primary product...

Embodiment 3

[0076] Harvest and select the inedible leaf sheath parts, remove the damage, and the same size of the first product of Zizania zizania; use the conveyor belt to transport the dust to the cold water pool to clean the surface dust, the temperature is less than 10°C, and the cleaning time is less than 5 minutes, and then the conveyor belt is transported to the disinfection pool To remove surface microorganisms, use 100-200ppm sodium hypochloride solution in the disinfection pool, soak for 2-3 minutes; then manually pour it into a cold plate and place it under the UV-C lamp. 0.3-0.5 meters below, control the irradiation dose to 4.20KJ m -2 , the irradiation time is 8-10 minutes; then it is transported to the hot water pool for heat shock treatment, the temperature is kept at 50-54°C, and the holding time is 30 seconds to 2 minutes; then the conveyor belt passes through the blower tunnel, and the air-dried wild rice stems are exposed to water; The conveyor belt is transported to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com