Ultrathin transparent nano/microstructure self-assembled film and its green preparation method

A micro-structure, self-assembly technology, applied in the field of materials science, can solve the problems of unsuitability for large-scale production, high equipment requirements, toxic solvents, etc., and achieve the effect of easy implementation, high transparency and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] An aspect of the embodiments of the present invention provides a green method for preparing an ultra-thin transparent nano / micro-structured self-assembled film, which includes:

[0045] (1) Disperse nano / microstructure (should be understood as nanostructure, microstructure or composite structure of the two) and / or nano / microstructure modification in the first liquid phase system to form nano / microstructure dispersion liquid;

[0046] (2) Spray the nano / micro structure dispersion liquid onto the surface of the second liquid phase system by spraying, and remove the second liquid phase system after the first liquid phase system volatilizes to obtain a nano / micro structure film;

[0047] (3) Squeeze the nano / micro-structured film by using liquid surface tension, so that the nano / micro-structured film self-assembles on the gas-liquid interface to form a dense and stable nano / micro-structured film to obtain a uniform structure Controllable nano / micro structured self-assemble...

Embodiment 1

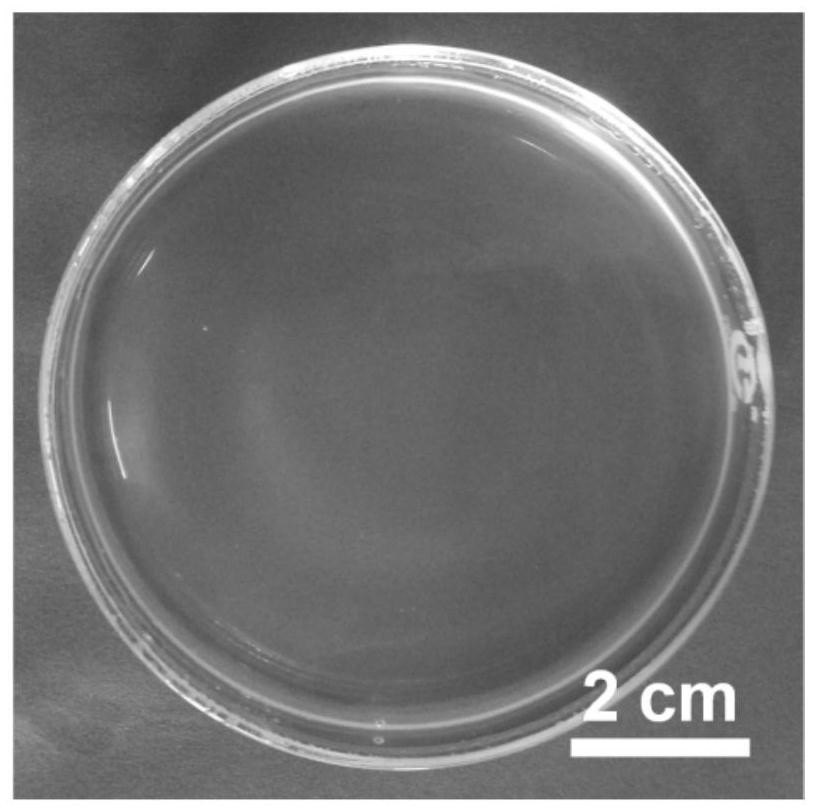

[0107] 1. If figure 1 with figure 2 As shown, take a certain amount of polystyrene microspheres and carry out ultrasonic dispersion with a certain amount of ethanol, the concentration is 2mg / mL;

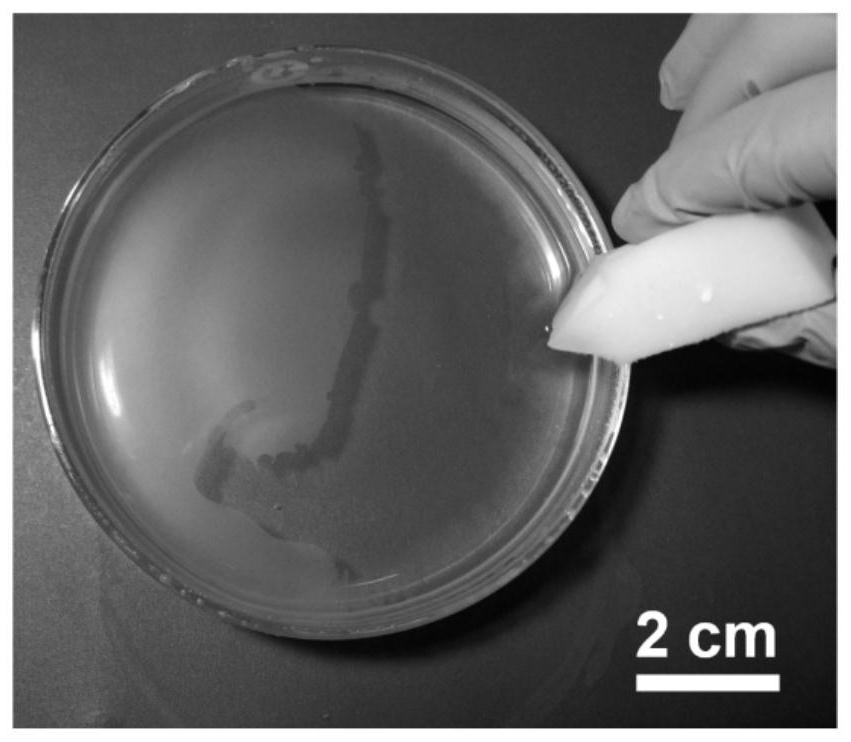

[0108] 2. Spray the polystyrene microsphere dispersion obtained in step 1 to the interface of the water through a sprayer at a spray speed of 5ml / min. During the spraying process, the size of the sprayed droplets is 5*10 -3 mm, then pump out the solution at a rate of 5ml / min through a peristaltic pump, and self-assemble for 800s at a temperature range of 20-60°C to form a polystyrene microsphere film with a thickness of 5-10μm;

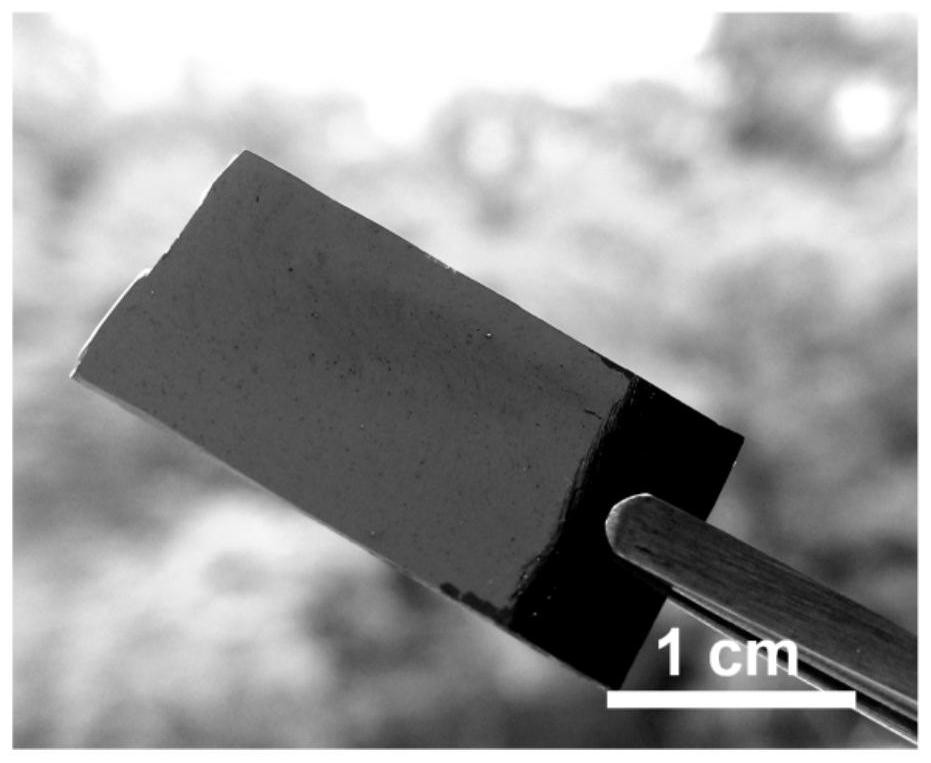

[0109] 3. The uniform and transparent polystyrene microsphere film obtained in step 2 is extruded at a pressure of 7.2mN / m for 60s by means of a peristaltic pump and other objects to absorb the interfacial liquid, and self-assembled at 40°C for 800s to form a uniform and transparent film. Dense polystyrene microsphere film;

[0110] 4. The polystyrene m...

Embodiment 2

[0114] 1. Take a certain amount of nano-gold modified polystyrene microspheres and use a certain amount of ethanol for ultrasonic dispersion, the concentration is 0.05mg / mL;

[0115] 2. Spray the nano-gold modified polystyrene microsphere dispersion obtained in step 1 onto the interface of carbon disulfide at a spray speed of 200ml / min through a sprayer. During the spraying process, the size of the sprayed droplets is 5*10 -1 mm, and then the solution was pumped out by a peristaltic pump at a rate of 20mL / min, thereby forming a nano-gold modified polystyrene microsphere film with a thickness of 5-10 μm;

[0116] 3. The uniform and transparent nano-gold modified polystyrene microsphere film obtained in step 2 is extruded at a pressure of 7.8mN / m for 5s by means of a peristaltic pump and other objects to absorb the interface liquid, and self-assembled at 20°C for 1000s to form Conductive uniform, transparent and dense nano-gold modified polystyrene microsphere film;

[0117] 4....

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com