A method for the separation and comprehensive utilization of all components of crop straw

A crop straw and full-component technology, applied in the fields of pulping with acid/acid anhydride, pulping with organic compounds, papermaking, etc., can solve the problems that the components cannot be completely separated, the purity of lignin is affected, and the cost of equipment is increased. , to achieve the effects of intensified degradation and dissolution, high recovery rate, and prevention of hydrolytic fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

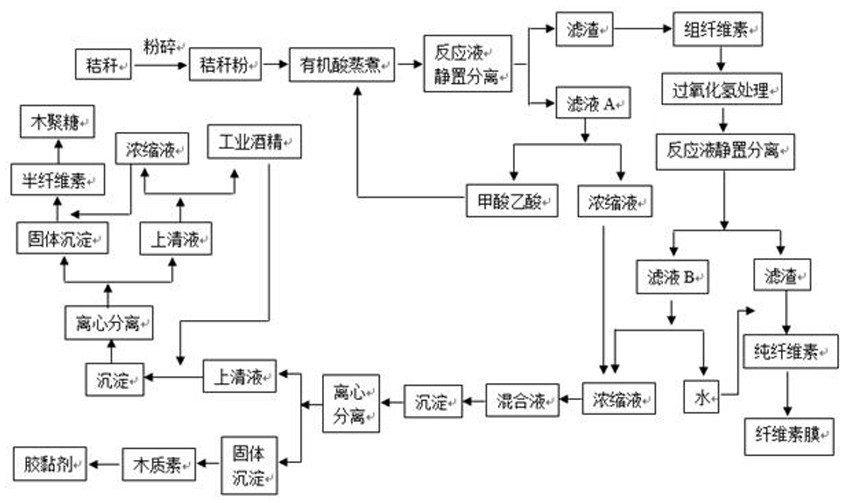

[0047] After crushing the corn stalks, sieve them with 40 meshes, wash them for later use, weigh 1000.0 g of the washed corn stalks, and cook the above-mentioned raw material stalks with a mixture of formic acid, acetic acid and water under the catalytic action of 0.1 mol / L dilute hydrochloric acid, wherein The volume ratio of formic acid, acetic acid and water is 30:60:10, the cooking temperature is controlled at 90°C, the solid-liquid mass ratio is 1:20, and the reaction time is 4h; after the reaction, the solid-liquid separation of the reaction liquid, the filtrate is collected as "A Liquid", the solid filter residue was washed with water until neutral, and dried at 60°C to obtain 445.0 g of crude cellulose.

[0048] The above crude cellulose is then treated with alkaline hydrogen peroxide. Wherein, the mass fraction of hydrogen peroxide solution is 5%, the pH of the control solution is 12, and the reaction is carried out at 60° C. for 3 hours, and the solid-liquid mass rat...

Embodiment 2

[0053] After crushing the corn stalks, sieve them with 40 meshes, wash them for later use, weigh 1000.0 g of the cleaned corn stalks, and cook the above-mentioned raw material stalks with a mixture of formic acid, acetic acid and water under the catalytic action of 0.2 mol / L dilute hydrochloric acid, wherein The volume ratio of formic acid, acetic acid and water is 30:60:10, the cooking temperature is controlled at 90°C, the solid-liquid mass ratio is 1:20, and the reaction time is 4h; after the reaction, the solid-liquid separation of the reaction liquid, the filtrate is collected as "A Liquid", the solid filter residue was washed with water until neutral, and dried at 60°C to obtain 463.0 g of crude cellulose.

[0054] The above crude cellulose is then treated with alkaline hydrogen peroxide. Among them, the mass fraction of hydrogen peroxide solution is 3%, the pH of the control solution is 12, and the reaction is carried out at 60° C. for 3 hours, and the mass ratio of sol...

Embodiment 3

[0059] After crushing the corn stalks, sieve them with 40 meshes, wash them for later use, weigh 1000.0 g of the washed corn stalks, and cook the above-mentioned raw material stalks with a mixture of formic acid, acetic acid and water under the catalytic action of 0.1 mol / L dilute hydrochloric acid, wherein The volume ratio of formic acid, acetic acid and water is 20:60:20, the cooking temperature is controlled at 90°C, the solid-liquid mass ratio is 1:20, and the reaction time is 4h; after the reaction, the solid-liquid separation of the reaction liquid, the filtrate is collected as "A Liquid", the solid filter residue was washed with water until neutral, and dried at 60°C to obtain 450.0 g of crude cellulose.

[0060] The above crude cellulose is then treated with alkaline hydrogen peroxide. Wherein, the mass fraction of hydrogen peroxide solution is 5%, the control solution pH=10, react at 60°C for 3 hours, and the solid-liquid mass ratio is 1:30; after the reaction, the so...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com