Resin-based nano-hydroxyapatite composite material, preparation method, and application of composite material in fluorine-polluted water treatment

A technology of nano-hydroxyapatite and composite materials, which is applied in water/sewage treatment, adsorption water/sewage treatment, water/sludge/sewage treatment, etc. pH impact, difficult separation and recovery, etc., to achieve the effect of solving the difficulty of separation and regeneration, low preparation cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

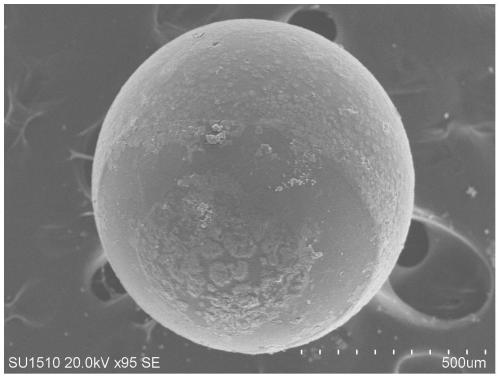

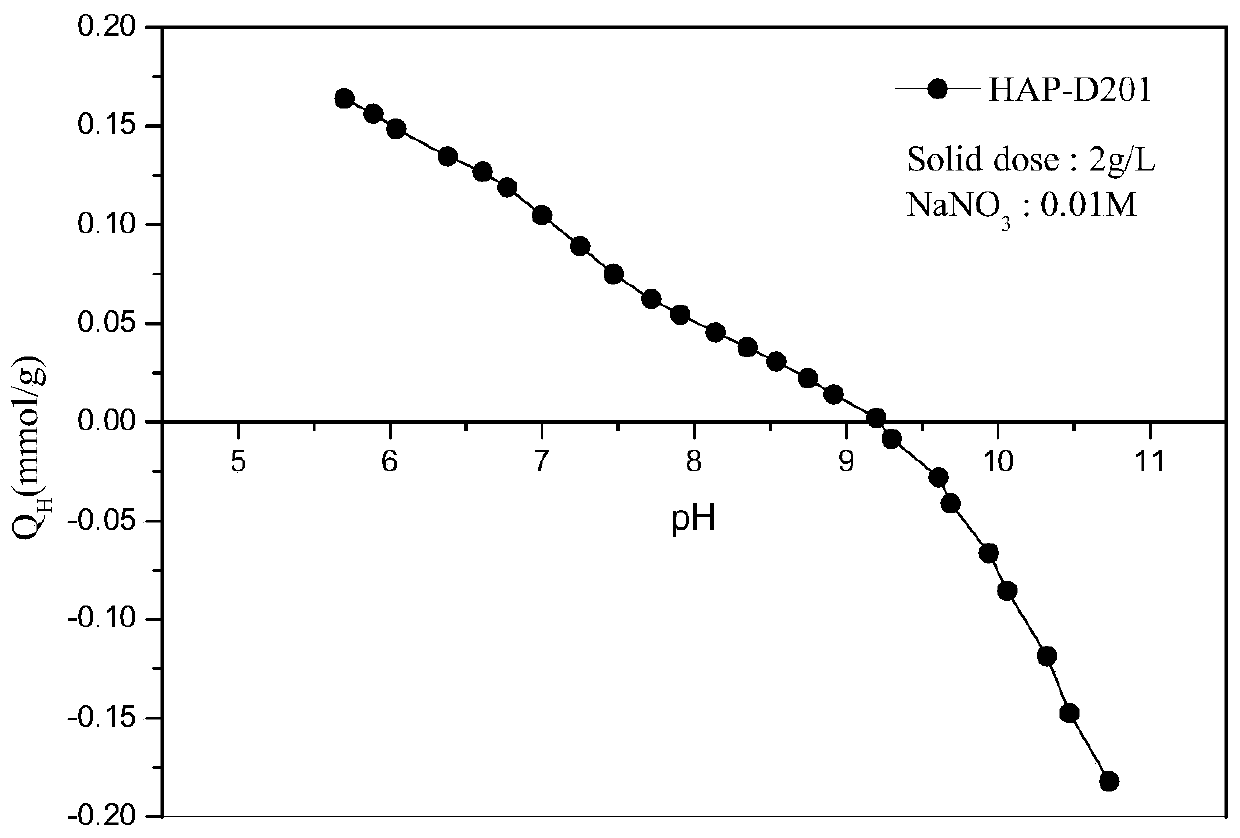

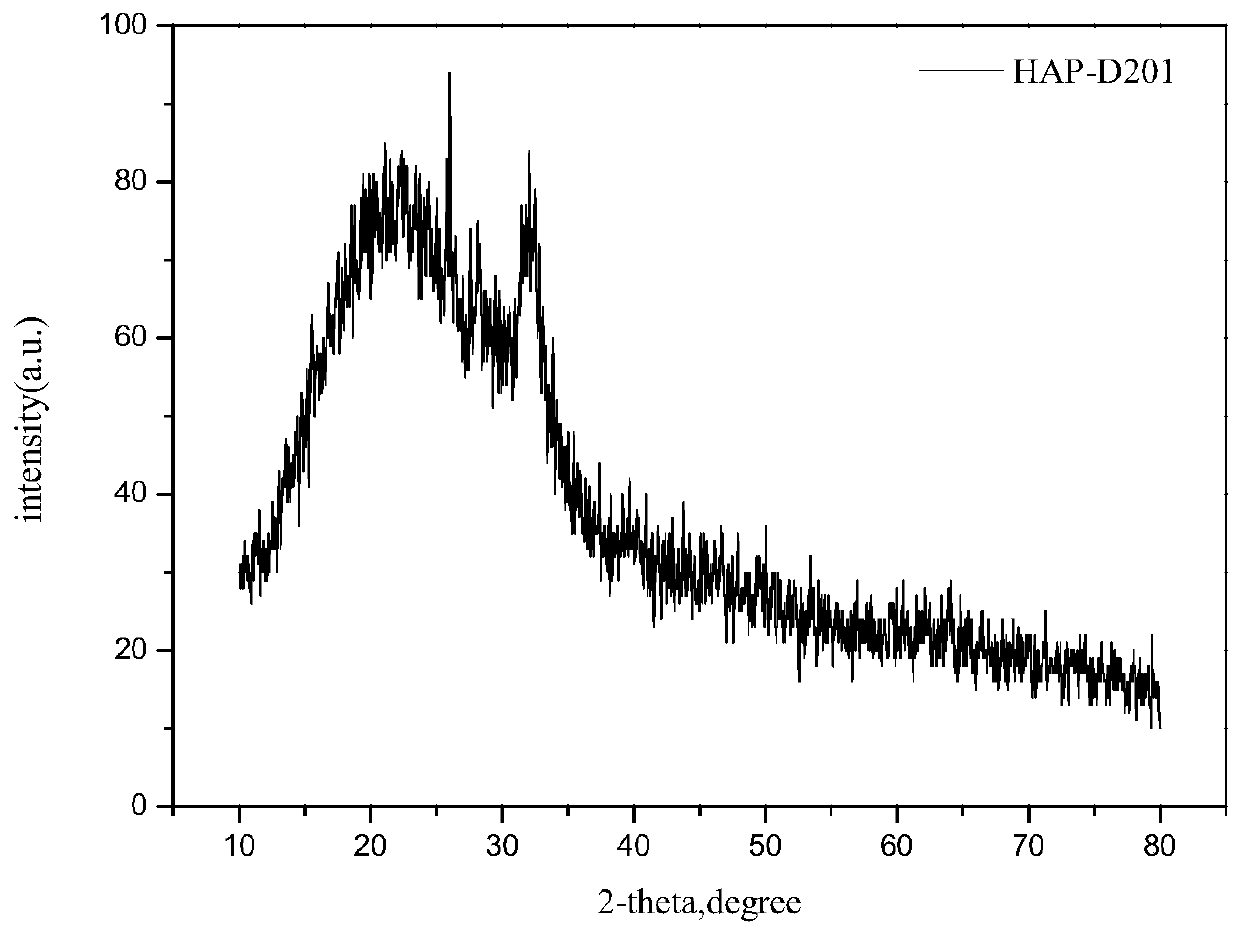

[0035] The resin-based nano-hydroxyapatite composite material HAP-D201 is obtained by immobilizing nano-hydroxyapatite particles on the macroporous strongly basic anion-exchange resin D201, and its average particle size is 0.8mm (such as figure 1 shown), the point of zero charge is 9.2 (as figure 2 shown), the crystal form is amorphous (as image 3 shown), the particle size of the immobilized nano-hydroxyapatite particles is 50nm (such as Figure 4 Shown), the HAP immobilization amount is 15%.

[0036] The specific preparation steps of the resin-based nano-hydroxyapatite composite material are as follows:

[0037] (1) 32.7880g Na 3 PO 4 Dissolve in 200mL water to get PO 4 3- Solution A with a concentration of 1M;

[0038] (2) 37.0673g CaCl 2 Dissolve in 200mL water to get Ca 2+ Solution B with a concentration of 1.67M;

[0039] (3) Weigh 5g of D201 resin in a three-necked flask, add solution A to it, mix and stir at 200rpm at 40°C for 12h, and make PO 4 3- Fully e...

Embodiment 2

[0048] The resin-based nano-hydroxyapatite composite material HAP-D301 was obtained by immobilizing nano-hydroxyapatite particles on macroporous weakly basic anion-exchange resin D301. The average particle size was 1.0mm, the zero charge point was 8.5, and the crystal form was Shaped, the diameter of the nano-hydroxyapatite particles immobilized is 60nm, and the immobilized amount of HAP is 12%.

[0049] The specific preparation steps of the resin-based nano-hydroxyapatite composite material are as follows:

[0050] (1) 32.7880g Na 3 PO 4 Dissolve in 200mL water to get PO 4 3- Solution A with a concentration of 1M;

[0051] (2) 37.0673g CaCl 2 Dissolve in 200mL water to get Ca 2+ Solution B with a concentration of 1.67M;

[0052] (3) Weigh 5g of D301 resin in a three-necked flask, add solution A to it, mix and stir at 200rpm at 40°C for 24h, and make PO 4 3- Fully exchanged to the surface and interior of the resin;

[0053] (4) Filter out the resin obtained in step (...

Embodiment 3

[0061] Resin-based nano-hydroxyapatite composite material HAP-201×4 was obtained by immobilizing nano-hydroxyapatite particles on gel-type strongly basic anion-exchange resin 201×4, with an average particle size of 0.6 mm and a zero charge point of 9.0 , the crystal form is amorphous, the diameter of the nano-hydroxyapatite particles immobilized is 50nm, and the immobilized amount of HAP is 14%.

[0062]The specific preparation steps of the resin-based nano-hydroxyapatite composite material are as follows:

[0063] (1) 32.7880g Na 3 PO 4 Dissolve in 200mL water to get PO 4 3- Solution A with a concentration of 1M;

[0064] (2) 37.0673g CaCl 2 Dissolve in 200mL water to get Ca 2+ Solution B with a concentration of 1.67M;

[0065] (3) Weigh 5g of 201×4 resin in a three-necked flask, add solution A to it, mix and stir at 25°C for 12h at a speed of 200rpm, and make PO 4 3- Fully exchanged to the surface and interior of the resin;

[0066] (4) Filter out the resin obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com