A method and device for desorption and recycling of thallium-containing titanium peroxide

A titanium peroxide and desorption technology, applied in chemical instruments and methods, separation methods, filtration and separation, etc., to achieve the effects of improving purity and washing effect, high desorption rate, and enhancing mixing and stirring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

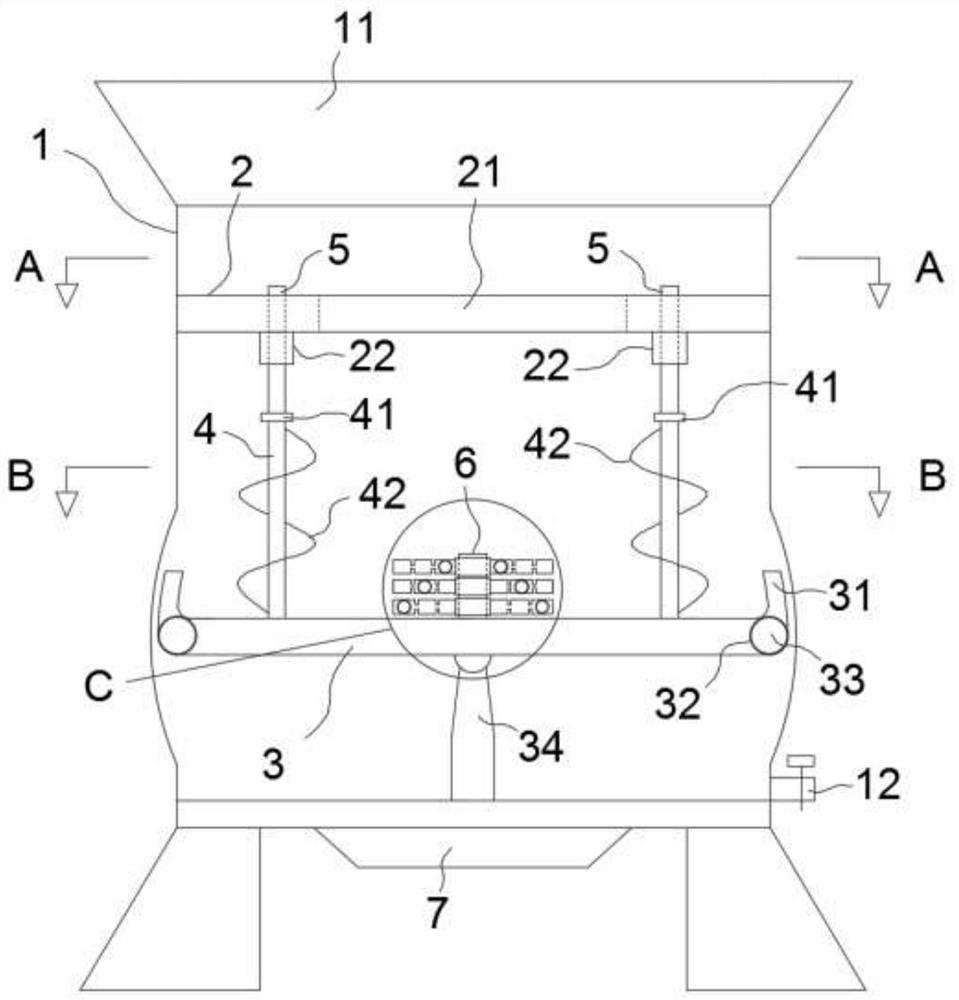

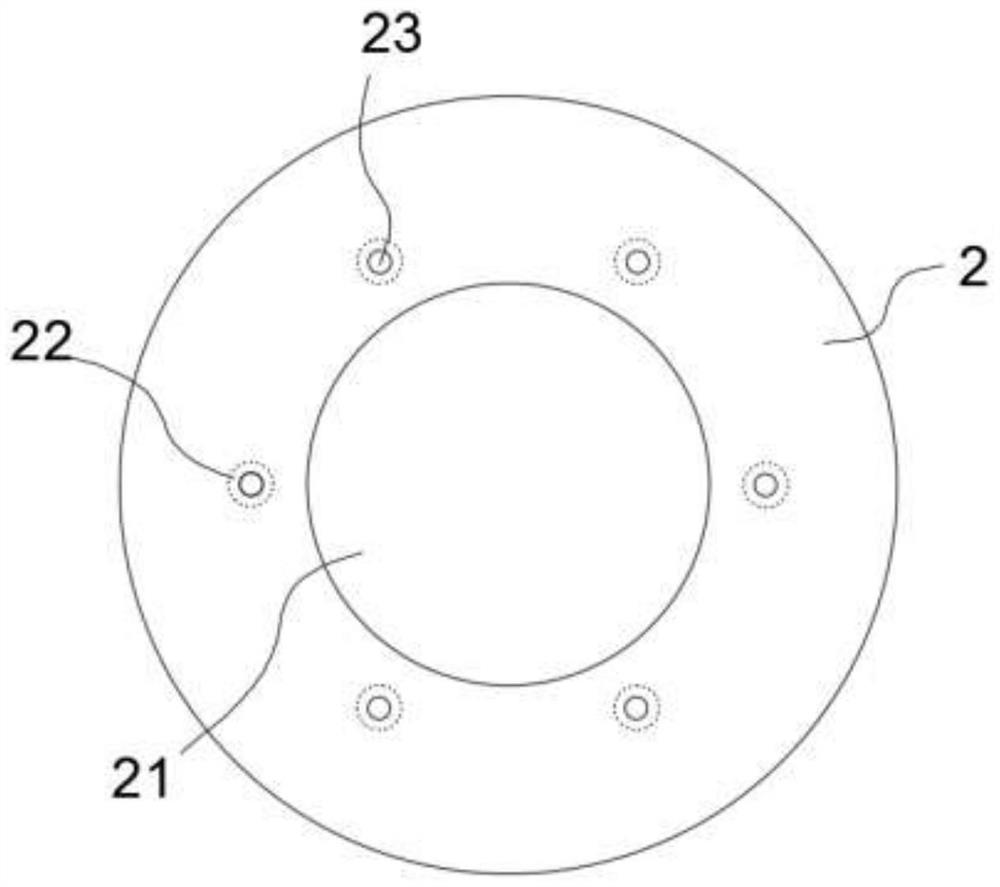

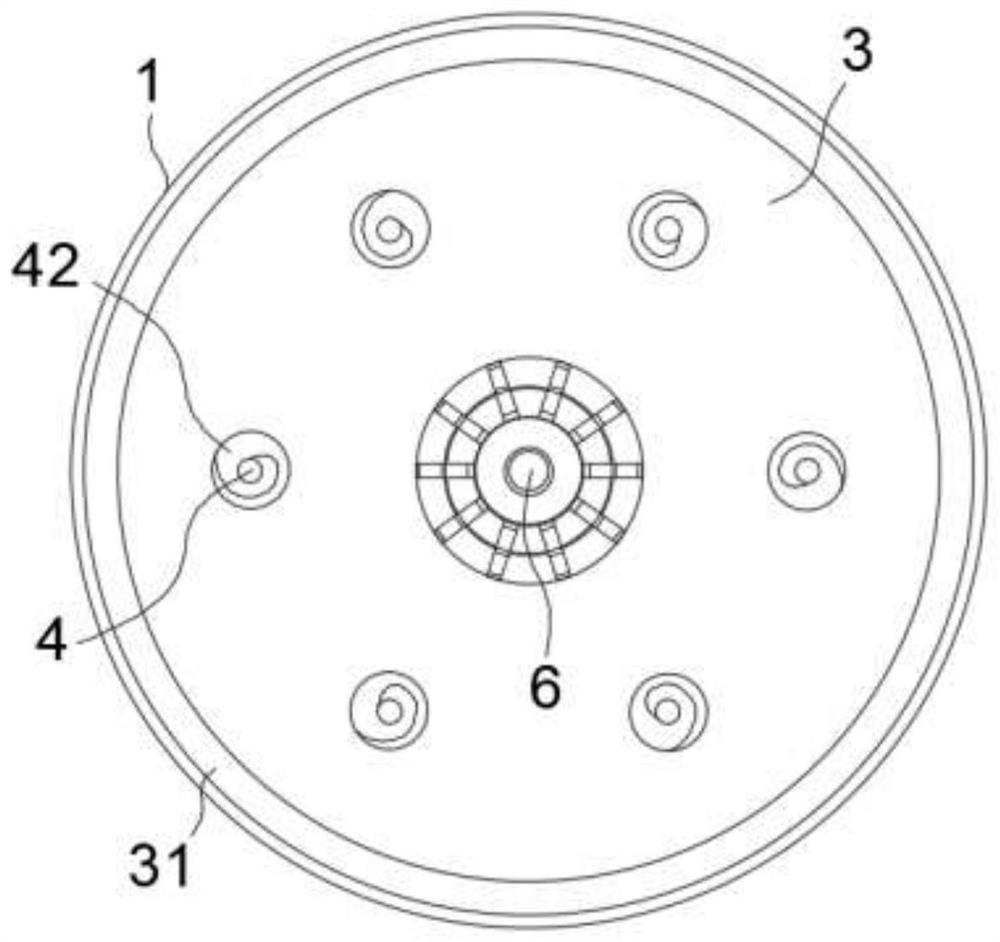

Method used

Image

Examples

Embodiment 1

[0036] A desorption recycling method containing thallium peroxide titanium, comprising the following steps:

[0037] S1: Using a desorption device to add titanium peroxide containing TL(I) to excess 1M HNO 3 In the solution, control the temperature at 20°C, stir for 7 minutes, and filter to obtain the primary precipitate; add 110kHz high-frequency ultrasonic waves during the period, and the ultrasonic intensity is 0.5w / cm 2 ;

[0038] S2: The primary precipitate obtained from the S1 solution was washed twice with deionized water, then the primary precipitate was reacted with concentrated sulfuric acid with a mass ratio of 0.8 times, boiled and filtered again to obtain clear liquid and precipitate A;

[0039] S3: Mix the clear liquid with 30% hydrogen peroxide mass concentration at a volume ratio of 2:1. After the reddish-brown solution is obtained, control the solution temperature at 52° C., and then add 10% ammonia mass concentration drop by drop until the solution The pH w...

Embodiment 2

[0049] The difference from Example 1 is that the temperature of the solution in S3 is controlled at 52°C; firstly, it is heated to 32°C, and then the temperature is raised to 52°C at 2°C / min, and ammonia water is added drop by drop during the temperature rise.

[0050] The titanium peroxide purity that embodiment 1 makes is 92.3%;

[0051] The titanium peroxide purity that embodiment 2 makes is 97.4%.

[0052] Conclusion: the purity of titanium peroxide obtained by the method of Example 2 is higher, up to 97.4%, which is more conducive to the subsequent re-adsorption use and improves the adsorption efficiency.

Embodiment 3

[0054] The difference from Example 1 is that it is washed with water before steam washing in S4. The water washing is washed with deionized water and supplemented with ultrasonic treatment. The ultrasonic wave adopts a combination of low frequency, high frequency and any two. 55kHz, high frequency is 130kHz.

[0055] Low frequency and high frequency: low frequency is 30kHz, high frequency is 130kHz, the purity of titanium peroxide is 99.2%;

[0056] Intermediate frequency and high frequency: the intermediate frequency is 55kHz, the high frequency is 130kHz, and the purity of titanium peroxide is 98.3%;

[0057] Low frequency and intermediate frequency: the low frequency is 30kHz, the intermediate frequency is 55kHz, the purity of titanium peroxide is 97.8%;

[0058] Conclusion: Compared with medium frequency plus high frequency and low frequency plus medium frequency, the dual frequency of low frequency plus high frequency is used for auxiliary ultrasonic treatment, which is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com