Method for preparing nopinone

A technology of nopinone and preparation process, which is applied in the field of organic synthesis and achieves the effects of high conversion rate, suitable reaction temperature and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

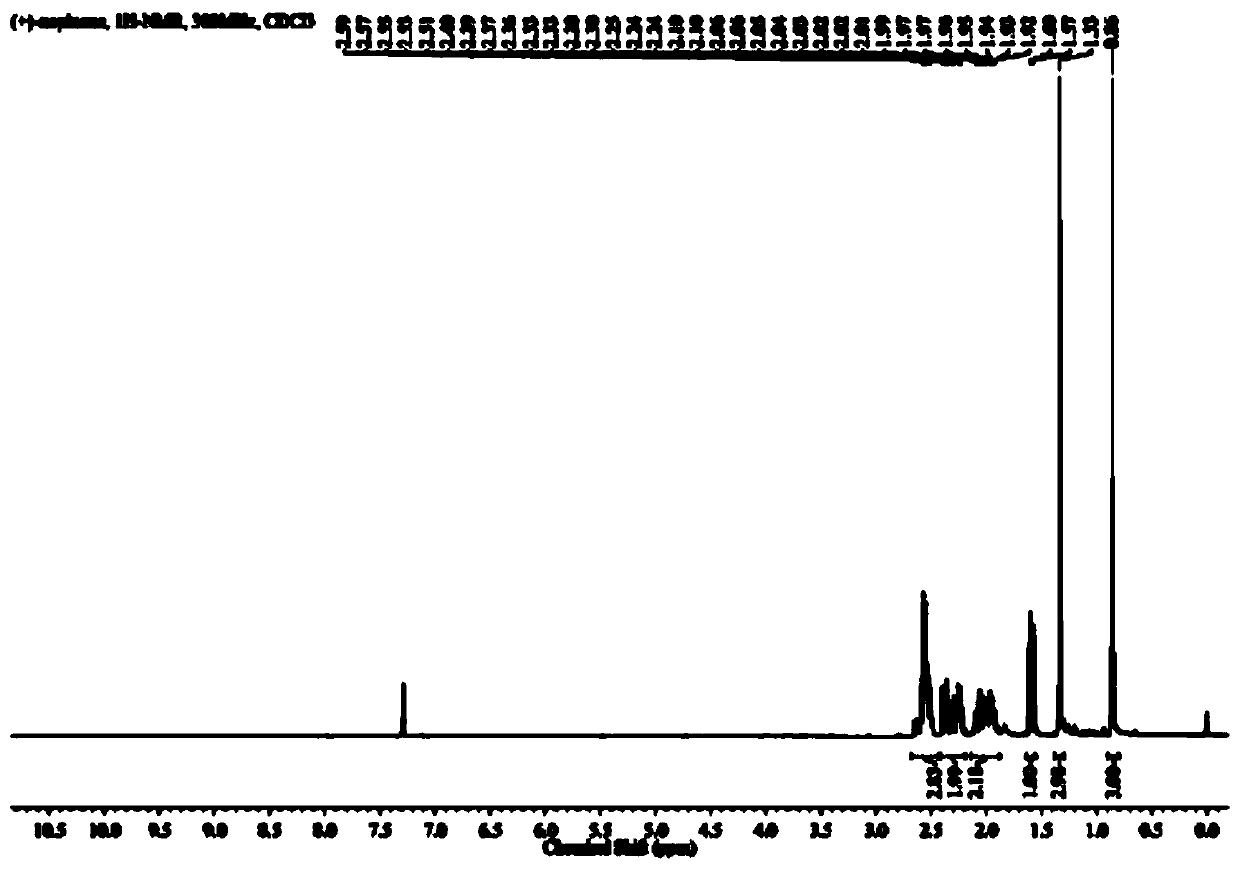

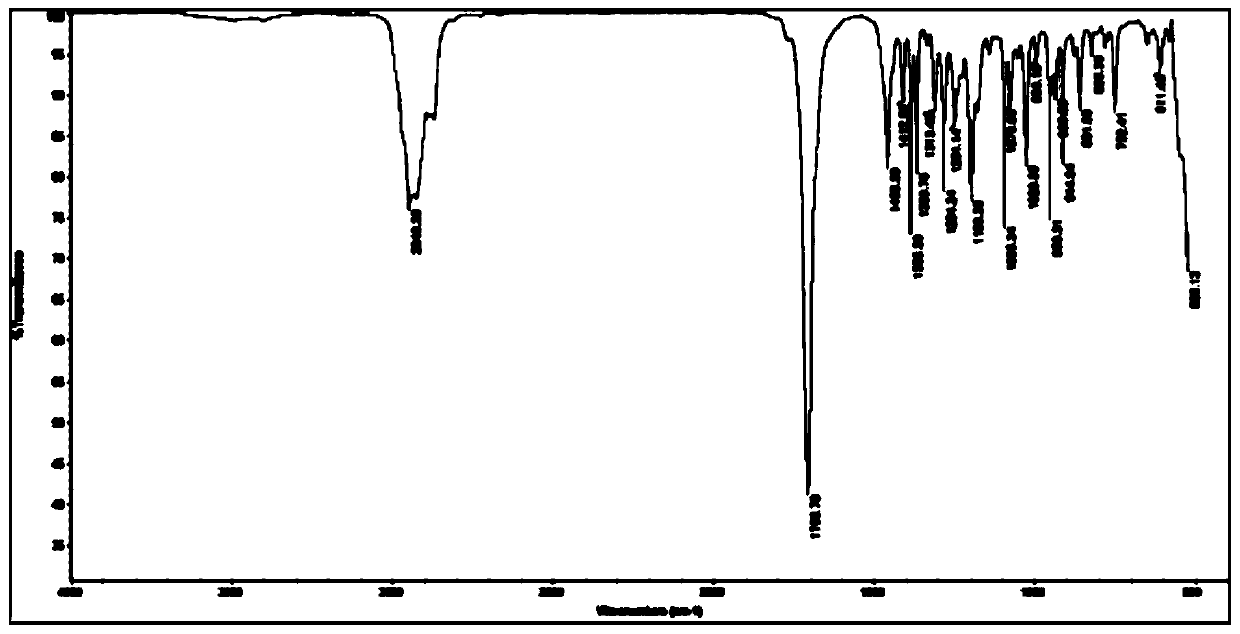

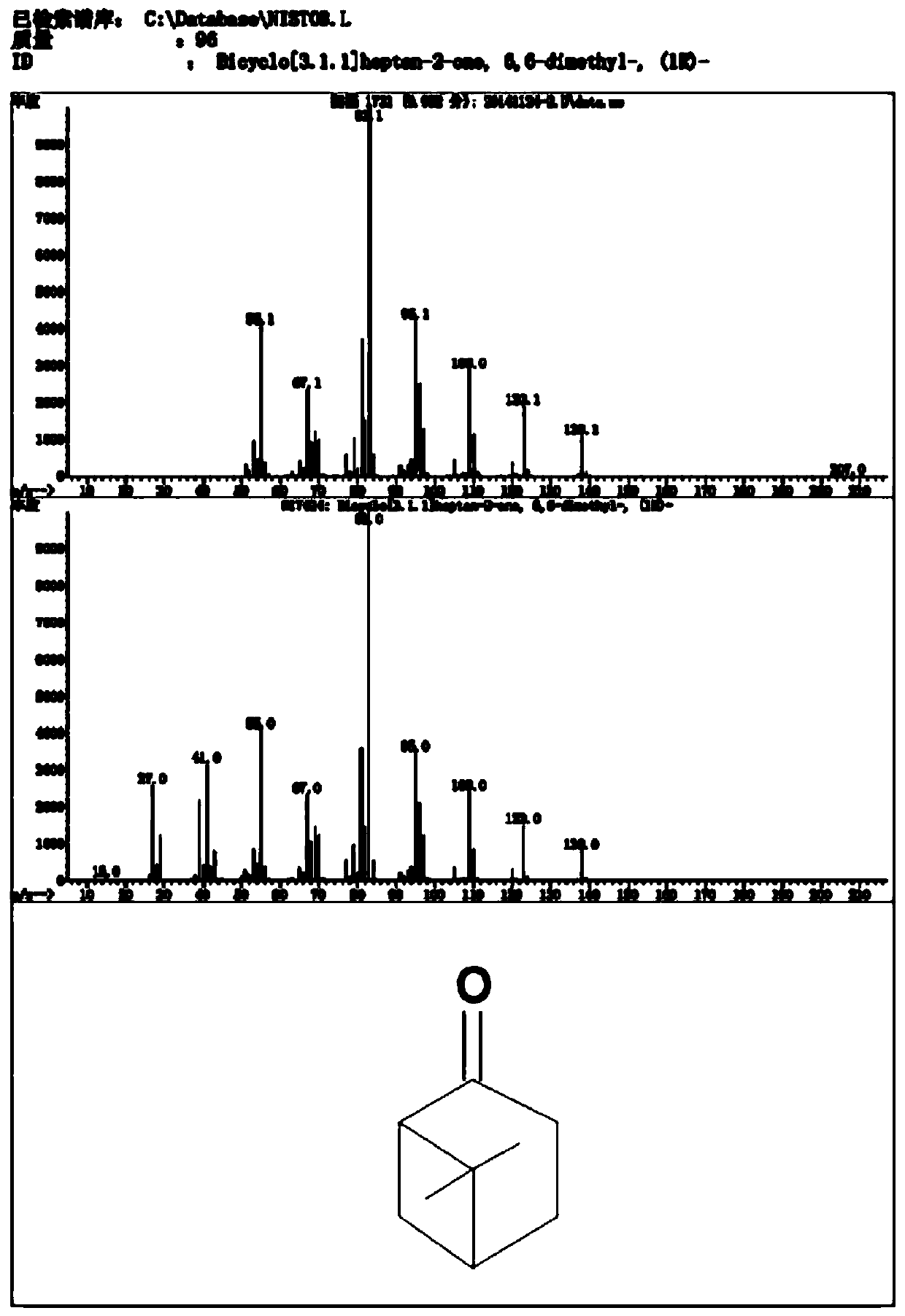

Image

Examples

Embodiment 1

[0020] A preparation method of nopinone, the reagents needed in the preparation process are: β-pinene, potassium permanganate, acetone, acid and catalyst, the preparation method steps are:

[0021] (1) Preparation: In the solvent acetone, mix β-pinene with the catalyst, then add potassium permanganate and acid, set the reaction temperature at 20-30°C, and continue the reaction time of 1-4h to obtain nopinene crude product;

[0022] (2) Purification: add 50mL ethyl acetate to the crude product of nopinone obtained above for extraction, then add a mass fraction of 5% sodium sulfite solution for washing, suction filtration, and the filtrate is washed with water and saturated saline, and finally Anhydrous sodium sulfate is dried to obtain the finished product of nopinone.

[0023] Wherein the catalyst is a surfactant, the molar ratio of β-pinene to potassium permanganate is 1:1 to 1:4, the molar ratio of β-pinene to acetone is 1:30 to 1:300, and the molar ratio of β-pinene to pot...

Embodiment 2

[0027] Take 5.000g (37mmol) of β-pinene in a 100mL three-necked flask, accurately weigh 0.2g (0.55mmol) of hexadecyltrimethylammonium bromide in the beaker, and continue to add 30mL of acetone and 3mL of soluble 2mol / L sulfuric acid to completely dissolve cetyl ammonium bromide, then pour it into a three-necked flask, use mechanical stirring, control the speed at 220r / min, and condense with a condenser. Keep the temperature steady at 21 °C. Add 18.6g (118mmol) potassium permanganate powder to there-necked flask, add in 1 minute. Continuous reaction 2h. After the reaction is completed, use 50 mL of ethyl acetate to wash twice and filter with suction. If the filtrate is purple, use an appropriate amount of 5% sodium sulfite solution for washing. After the filtrate is purple, a solid precipitate of manganese dioxide will be produced. , and then filter. Use 75mL water to wash 2 times, then wash with 80mL saturated salt water (2 times), after detecting neutrality with pH test pa...

Embodiment 3

[0029] Take 5.000g (37mmol) of β-pinene in a 100mL three-necked flask, accurately weigh 0.2g (2.2mmol) of 2-bromoethyltrimethylammonium bromide in the beaker, and continue to add 30mL of acetone and 2.5mL of Hydrochloric acid with a solubility of 2mol / L completely dissolves 2-bromoethyltrimethylammonium bromide, then pours it into a three-necked flask, uses mechanical stirring, controls the speed at 220 r / min, and condenses with a condenser tube. Keep the temperature steady at 23°C. Add 15.0g (95mmol) potassium permanganate powder to the three-necked flask, and finish adding within 1 minute. Continuous reaction 3h. After the reaction is completed, use 50 mL of ethyl acetate to wash twice and filter with suction. If the filtrate is purple, use an appropriate amount of 5% sodium sulfite solution for washing. After the filtrate is purple, a solid precipitate of manganese dioxide will be produced. , and then filter. Use 75mL of water to wash twice, and then wash twice with 80mL...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap