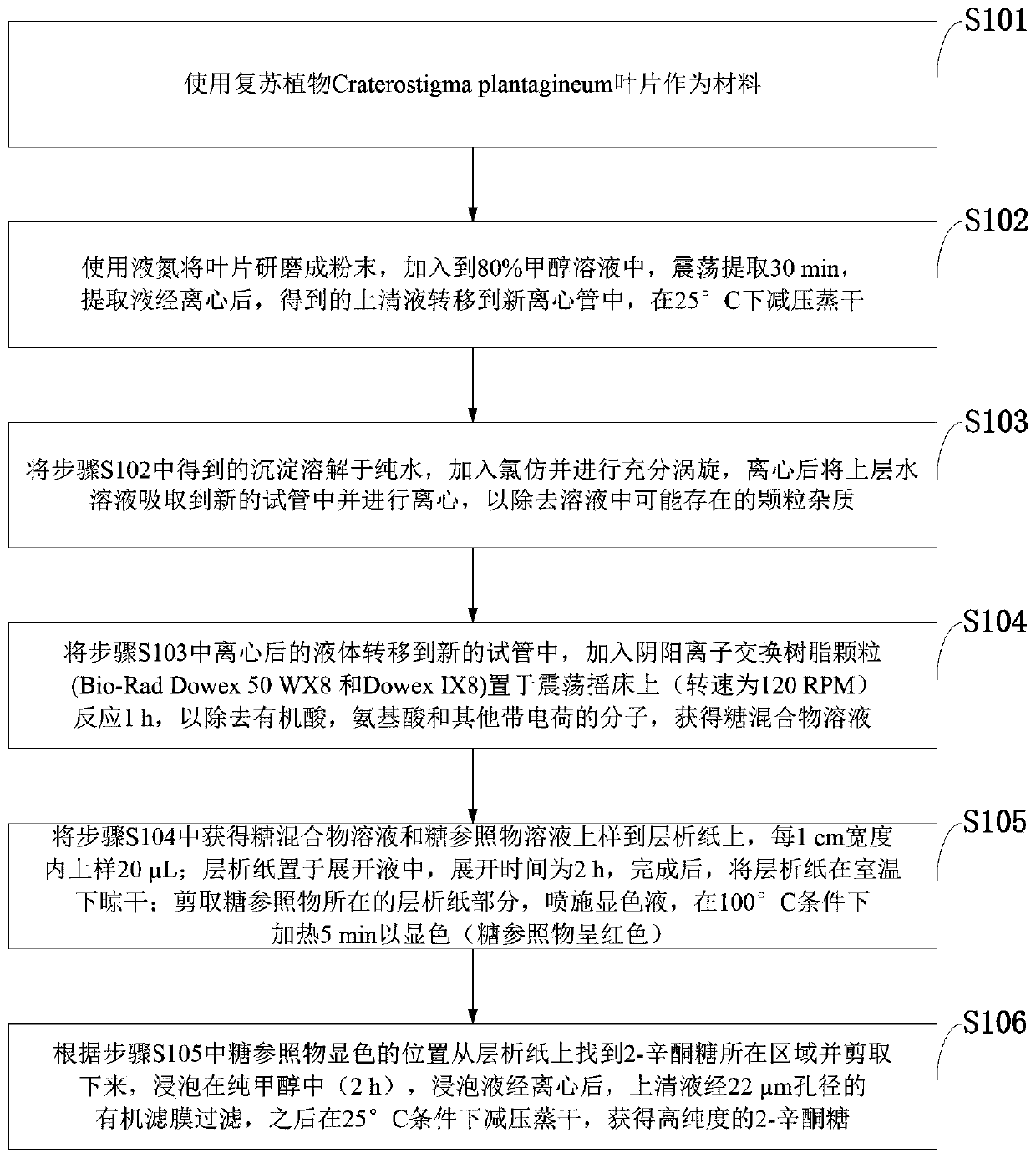

Method for preparing plant pure 2-octulose in small quantities

A technology of octanulose and pure product is applied in the field of small-scale preparation of pure 2-octanulose of plants, and can solve the problem that there is no relevant research report on the preparation method of pure 2-octanulose, scientific research and product development to be carried out, Limit the research and development of 2-octanulose, and achieve the effect of good application prospects, easy widespread application, and easy implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

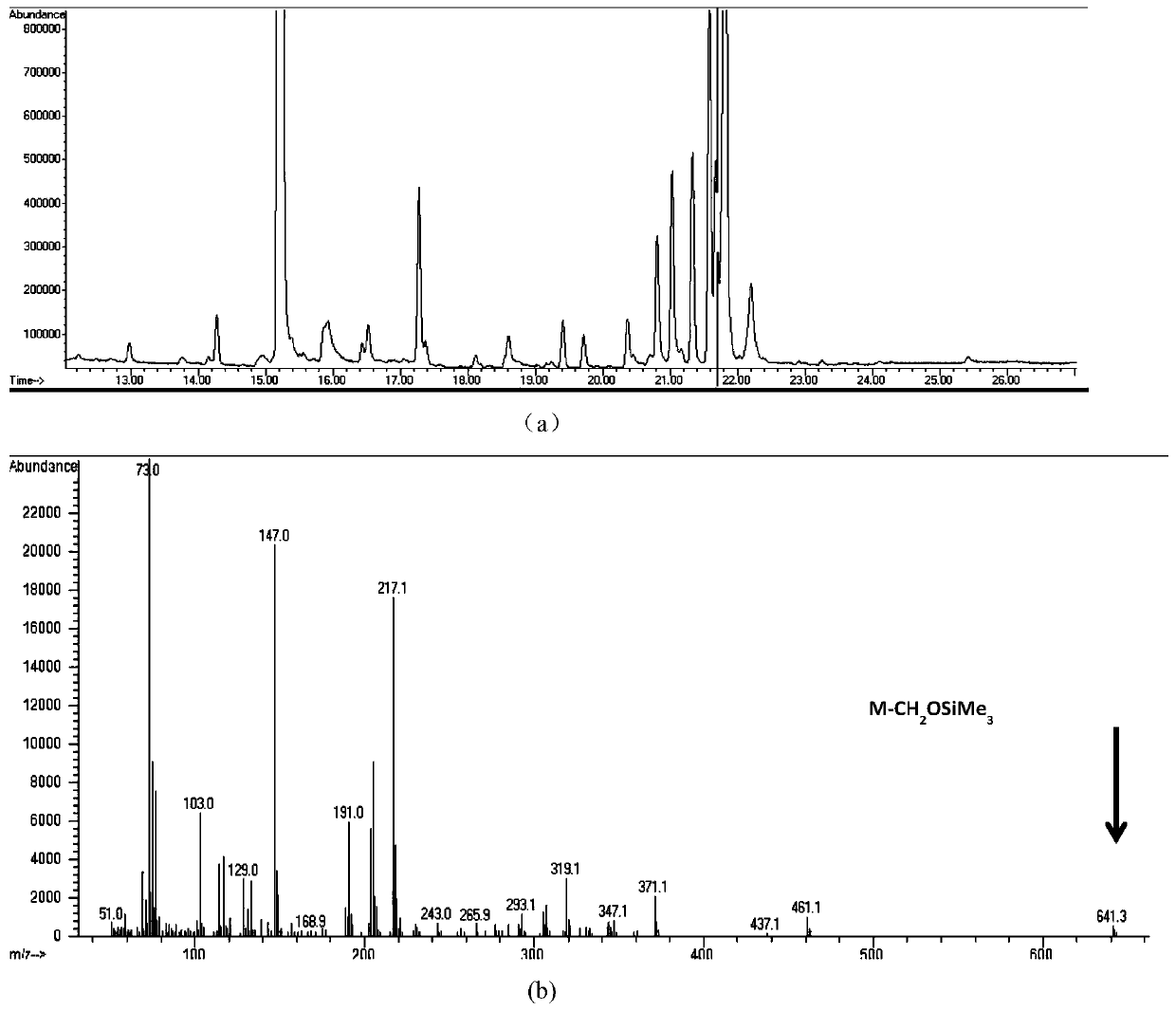

Embodiment 1

[0047] The fresh leaves of the revived plant Craterostigma plantagineum in normal growth were ground into powder with liquid nitrogen, and then 1 g of the powder was weighed and added to 1 mL of 80% methanol solution, and extracted by shaking for 30 min. After the extract was centrifuged at 10,000 g for 5 min, the obtained supernatant was transferred to a new centrifuge tube; the precipitate was repeatedly extracted three times with 80% methanol solution, and the supernatant obtained after centrifugation was transferred and combined into a new test tube. The obtained supernatant was evaporated to dryness under reduced pressure at 25° C. using an Eppendorf concentrator to obtain a precipitate. After the precipitate is fully dissolved in 1mL pure water, add 500μL chloroform to the aqueous solution, vortex fully, centrifuge at 10000g for 3min to separate the solution, draw the upper layer solution into a new test tube, add 500μL chloroform again, and vortex fully, Centrifuge at 1...

Embodiment 2

[0049] The fresh leaves of the revived plant Craterostigma Plantagineum in normal growth were ground into powder with liquid nitrogen, and then 5 g of the powder was weighed and added to 10 mL of 80% methanol solution, and extracted by shaking for 30 min. After the extract was centrifuged at 10,000 g for 5 min, the obtained supernatant was transferred to a new centrifuge tube; the precipitate was repeatedly extracted three times with 80% methanol solution, and the supernatant obtained after centrifugation was transferred and combined into a new test tube. The obtained supernatant was evaporated to dryness under reduced pressure at 25° C. using an Eppendorf concentrator to obtain a precipitate. After the precipitate is fully dissolved in 5mL pure water, add 2.5mL chloroform to the aqueous solution, vortex fully, centrifuge at 10000g for 3min to separate the solution, draw the upper layer solution into a new test tube, add 2.5mL chloroform again, and vortex fully Afterwards, cen...

Embodiment 3

[0051] The fresh leaves of the revived plant Craterostigma Plantagineum in normal growth were ground into powder with liquid nitrogen, and then 10 g of the powder was weighed and added to 10 mL of 80% methanol solution, and extracted by shaking for 30 min. After the extract was centrifuged at 10,000 g for 5 min, the obtained supernatant was transferred to a new centrifuge tube; the precipitate was repeatedly extracted three times with 80% methanol solution, and the supernatant obtained after centrifugation was transferred and merged into a new petri dish. The obtained supernatant was evaporated to dryness at 50° C. using a heating metal block to obtain a precipitate. After the precipitate is fully dissolved in 5mL pure water, add 2.5mL chloroform to the aqueous solution, vortex fully, centrifuge at 10000g for 3min to separate the solution, draw the upper layer solution into a new test tube, add 2.5mL chloroform again, and vortex fully Afterwards, centrifuge at 10000g for 3min ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com