Environmentally-friendly wear-resistant non-slip foam composite material used for shoes and preparation method of composite material

A composite material and environmentally friendly technology, applied in applications, footwear, clothing, etc., can solve problems such as product failure, and achieve good compatibility, less additives, and obvious wear-resistant and anti-skid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

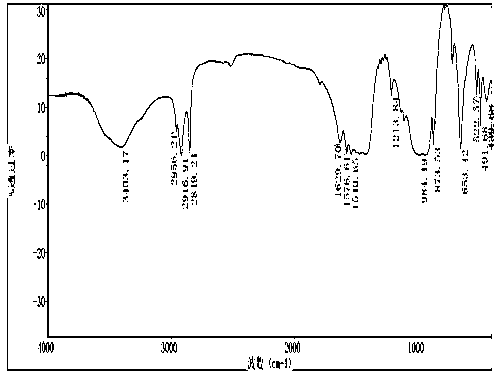

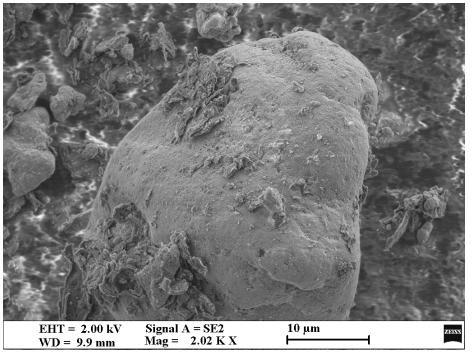

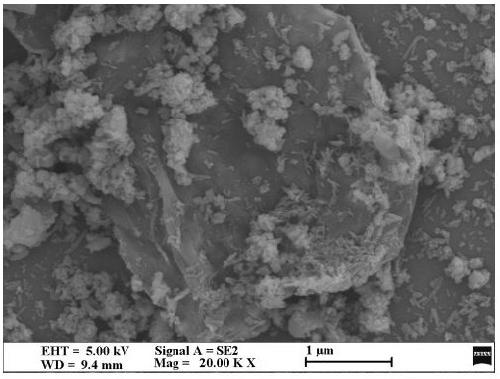

Image

Examples

Embodiment 1

[0026] A method for preparing an environmentally friendly wear-resistant anti-skid foam composite material for shoes, the specific steps are:

[0027] 1) Preparation of graphene oxide template: 1 g of expanded graphite was dissolved in 23 mL of concentrated sulfuric acid, placed in a magnetic stirrer for stirring, and after it was uniformly dispersed, 3 g of potassium permanganate and 1 g of sodium nitrate were slowly added, and the Add within one hour; after another 2 hours of reaction, start to heat up to 98°C, when the solution system becomes thick, add 44ml of deionized water and 5ml of 5wt% hydrogen peroxide solution dropwise, and titrate into the solution with 5wt% hydrochloric acid The reaction ends when no more bubbles are produced; the prepared graphene oxide is washed with deionized water, centrifuged, and freeze-dried;

[0028] 2) Preparation of graphene oxide-coated desulfurization ash nanomaterials: Add 200mg of graphene oxide prepared in step 1) into a flask, add...

Embodiment 2

[0033] A method for preparing an environmentally friendly wear-resistant anti-skid foam composite material for shoes, the specific steps are:

[0034] 1) Preparation of graphene oxide template: 1 g of expanded graphite was dissolved in 23 mL of concentrated sulfuric acid, placed in a magnetic stirrer for stirring, and after it was uniformly dispersed, 3 g of potassium permanganate and 1 g of sodium nitrate were slowly added, and the Add within one hour; after another 2 hours of reaction, start to heat up to 98°C, when the solution system becomes thick, add 44ml of deionized water and 5ml of 5wt% hydrogen peroxide solution dropwise, and titrate into the solution with 5wt% hydrochloric acid The reaction ends when no more bubbles are produced; the prepared graphene oxide is washed with deionized water, centrifuged, and freeze-dried;

[0035]2) Preparation of graphene oxide-coated desulfurization ash nanomaterials: Add 200mg of graphene oxide prepared in step 1) into a flask, add ...

Embodiment 3

[0040] A method for preparing an environmentally friendly wear-resistant anti-skid foam composite material for shoes, the specific steps are:

[0041] 1) Preparation of graphene oxide template: 1 g of expanded graphite was dissolved in 23 mL of concentrated sulfuric acid, placed in a magnetic stirrer for stirring, and after it was uniformly dispersed, 3 g of potassium permanganate and 1 g of sodium nitrate were slowly added, and the Add within one hour; after another 2 hours of reaction, start to heat up to 98°C, when the solution system becomes thick, add 44ml of deionized water and 5ml of 5wt% hydrogen peroxide solution dropwise, and titrate into the solution with 5wt% hydrochloric acid The reaction ends when no more bubbles are produced; the prepared graphene oxide is washed with deionized water, centrifuged, and freeze-dried;

[0042] 2) Preparation of graphene oxide-coated desulfurization ash nanomaterials: Add 200mg of graphene oxide prepared in step 1) into a flask, add...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com