A rotating metal target and its preparation method and device

A metal target and metal pipe technology, applied in metal material coating process, vacuum evaporation coating, coating and other directions, can solve problems such as unfavorable preparation of high-purity aluminum targets, difficult process control, expensive processing equipment, etc. problem, to achieve the effect of cheap processing equipment, low cost, and grain size refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

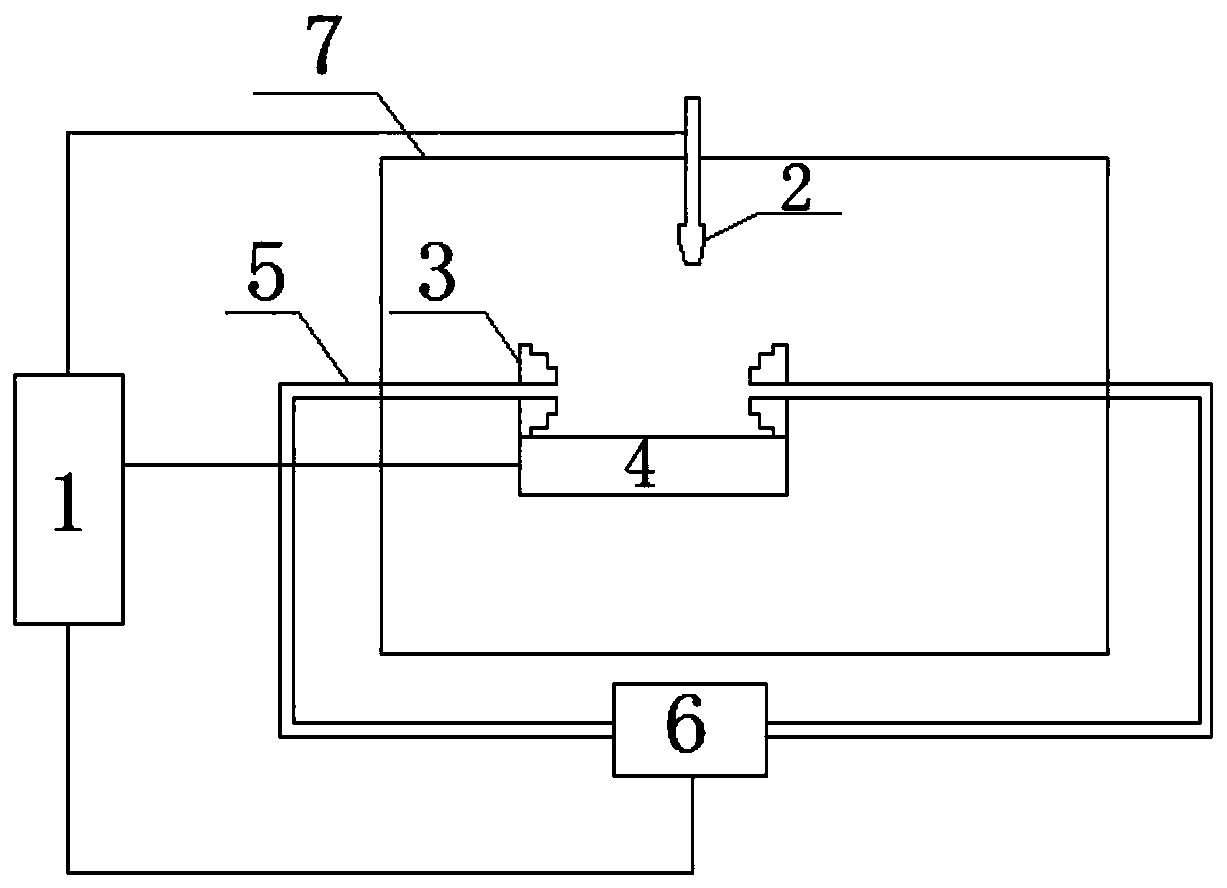

[0030] The invention provides a method for preparing a rotating metal target, comprising the following steps:

[0031] Under vacuum conditions, the metal tube is subjected to high-energy electron beam regional remelting treatment and then cooled to obtain a rotating metal target.

[0032] In the present invention, the metal pipes preferably include aluminum pipes, copper pipes or titanium pipes, the purity is preferably >99.999%, the outer diameter is preferably 150-180mm, more preferably 150-165mm, and the inner diameter is preferably 110-120mm, further It is preferably 120 mm, and the length is preferably 500 to 3000 mm, more preferably 850 to 2940 mm. In the present invention, the metal pipe is preferably cast by vacuum arc melting process. The present invention has no special limitation on the specific operation of the vacuum arc melting process, and the vacuum arc melting process well known to those skilled in the art can be used. The invention adopts the metal pipe mat...

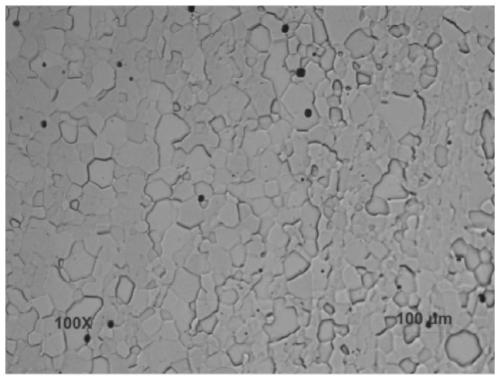

Embodiment 1

[0060] High-purity aluminum ingots (>99.999%) are melted and cast into aluminum tubes by vacuum arc melting. The specifications of the aluminum tubes are outer diameter OD=150mm, inner diameter ID=120mm, length L=860mm;

[0061] Install the prepared aluminum tube on a movable rotary table, and connect it with a cooling water pipe, pass constant temperature cooling water inside the aluminum tube, set the cooling water temperature to 15°C, and the flow rate to 2m / s;

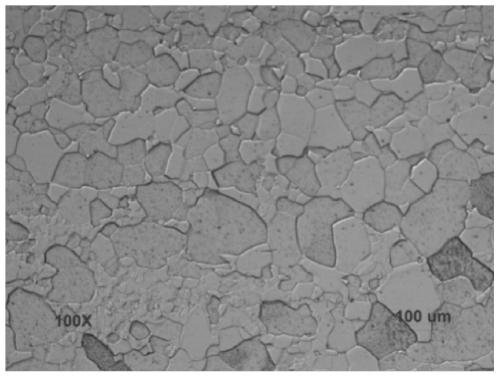

[0062] In a vacuum of 10 -2 In the vacuum chamber of Pa, high-energy electron beams are used to remelt the pipe area. Adjust the electron beam output power to 15kW, the accelerating voltage to 60kV, and the scanning current to 250mA. Form a small molten pool with a diameter of 4mm and a depth of about 12mm on the surface of the aluminum tube;

[0063] According to the thickness of the metal pipe T=15mm (T=(OD-ID) / 2), set the rotational speed of the aluminum pipe to 1.5m / min and the horizontal movement speed of th...

Embodiment 2

[0067] High-purity aluminum ingots (>99.999%) are melted and cast into aluminum tubes by vacuum arc melting. The specifications of the aluminum tubes are outer diameter OD=175mm, inner diameter ID=120mm, and length L=2950mm;

[0068] Install the prepared aluminum tube on a movable rotary table, and connect it with a cooling water pipe, pass constant temperature cooling water inside the aluminum tube, set the cooling water temperature to 15°C, and the flow rate to 2m / s;

[0069] In a vacuum of 10 -2 In the vacuum chamber of Pa, high-energy electron beams are used to remelt the pipe area. Adjust the electron beam output power to 25kW, the accelerating voltage to 71.4kV, and the scanning current to 350mA. Form a small molten pool with a diameter of 5mm and a depth of about 24mm on the surface of the aluminum tube;

[0070] According to the thickness T=27.5mm (T=(OD-ID) / 2) of the metal pipe, set the rotational speed of the aluminum pipe to 2.5m / min and the horizontal movement sp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com