MnOx-MOF-Gr composite material and preparation method and application thereof

A technology of mnox-mof-gr and composite materials, applied in the field of composite materials, can solve problems such as poor formaldehyde removal effect, and achieve the effects of improving adsorption performance, improving catalytic oxidation performance, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A kind of MnO x -The preparation method of MOF-Gr-1 composite material, comprising:

[0031] (1) Preparation of Mn-MOFs material: 1.2g of manganese chloride tetrahydrate and 0.3g of terephthalic acid were fully dissolved in a mixture containing 3mL of water and 15mL of N,N dimethylformamide (DMF), and then the mixture was Heat water at 100-160°C for 1-5 hours, filter, wash and dry the reactant to obtain Mn-MOFs crystal material;

[0032] (2) Mix Mn-MOFs material with graphene dispersion: add 5mg graphene into 10mL deionized water and ultrasonically disperse for 10-30min to obtain graphene dispersion, then add Mn-MOFs to graphene dispersion and stir ultrasonically to disperse the mixture evenly;

[0033] (3) Preparation of oxidant solution: take 5g potassium permanganate and dissolve it in 40mL deionized water to ensure complete dissolution to obtain oxidant solution;

[0034] (4) Fully mix the mixed solution prepared in step (2) with the oxidant solution prepared in ...

Embodiment 2

[0039] A kind of MnO x -The preparation method of the MOF-Gr-2 composite material is basically the same as the method in Example 1, the difference is that in step (2), the amount of graphene is 15mg. The yield of Example 2 was also 50%.

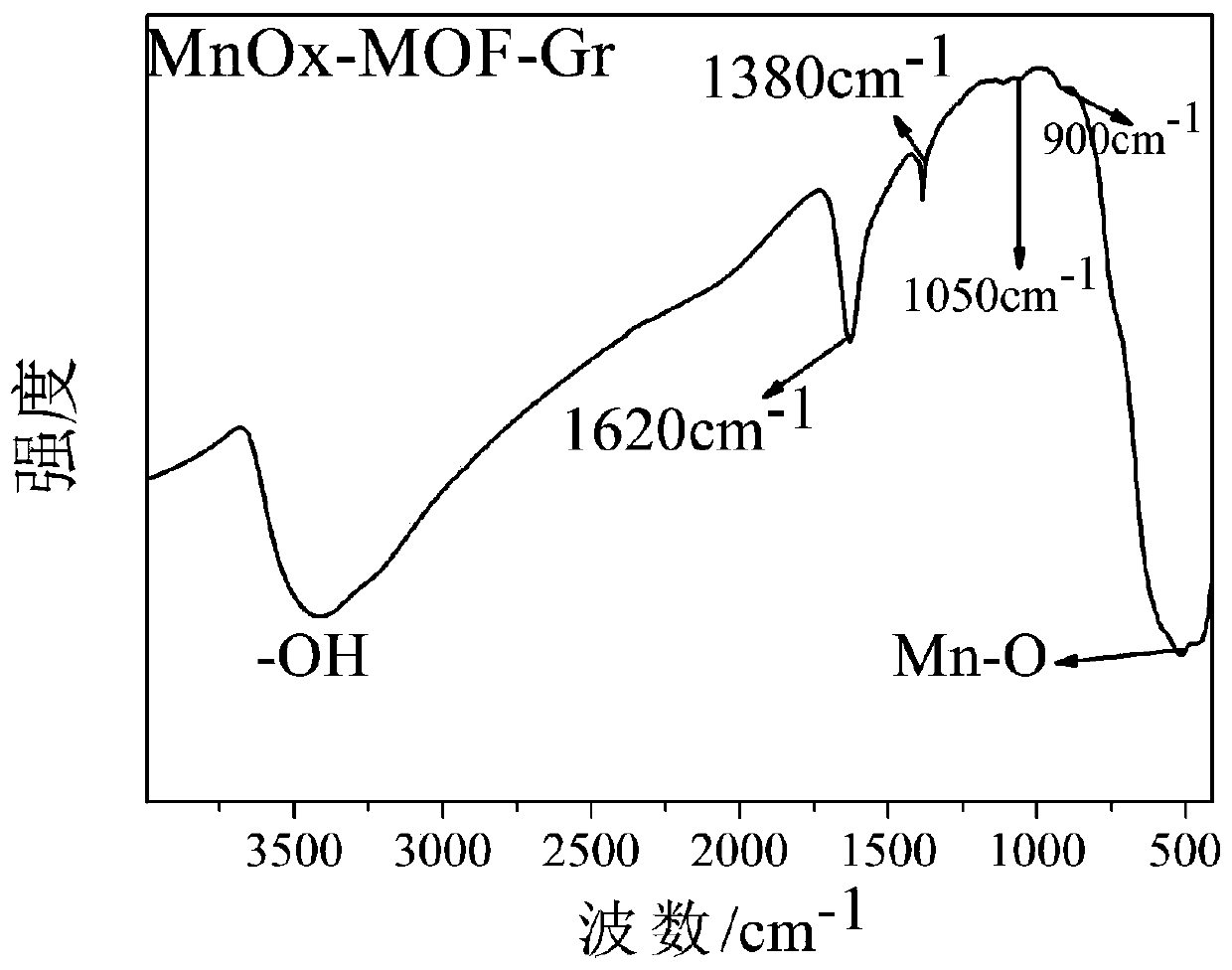

[0040] Such as figure 1 Shown, is the MnO prepared by Example 2 of the present invention x - The FT-IR spectrum of the MOF-Gr-2 composite material, qualitatively determined the surface groups of the catalyst, located at 3400cm in the figure -1 The peak is the infrared characteristic absorption peak of -OH, located at 500cm -1 The peak is the absorption peak of the Mn-O bond, which verifies the generation of manganese dioxide in the product. Located at 1620cm -1 , 1050cm -1 and 900cm -1 The infrared absorption peaks of corresponding to the C=C stretching vibration absorption peak in aromatics, the C-OH stretching vibration absorption peak in alkoxy groups and the C-O stretching vibration in epoxides, these representative oxygen-containi...

Embodiment 3

[0050] A kind of MnO x -The preparation method of the MOF-Gr-3 composite material is basically the same as the method in Example 1, the difference is that in step (2), the amount of graphene is 25 mg.

[0051] Adopt the same testing method as embodiment 1 to the MnO prepared by present embodiment 3 x -1.0mg / m of MOF-Gr-3 composite material 3 The low-concentration formaldehyde catalytic oxidation static test experiment, the specific implementation method is as follows:

[0052] Weigh 0.1g of the MnO prepared in Example 3 x -MOF-Gr-3 composite material, put it in a petri dish and seal the petri dish with plastic wrap and put it into a formaldehyde reactor. The volume of the reactor is 150L. Seal it, place the formaldehyde volatilization device in the reaction chamber, wait for it to volatilize completely, after reaching equilibrium, put the MnO x - The MOF-Gr-3 composite is fully exposed to the air containing formaldehyde in the reactor.

[0053] Measure the MnO prepared by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com