Functional graphene/montmorillonite/modified molybdenum sulfide lubricating oil additive

A lubricating oil additive and molybdenum sulfide technology, which is applied in the direction of additives, petroleum industry, lubricating composition, etc., can solve the problems of unreported friction surface repair ability, insufficient friction coefficient, friction coefficient reduction, etc., and achieve a significant intelligent repair effect , low cost, and the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

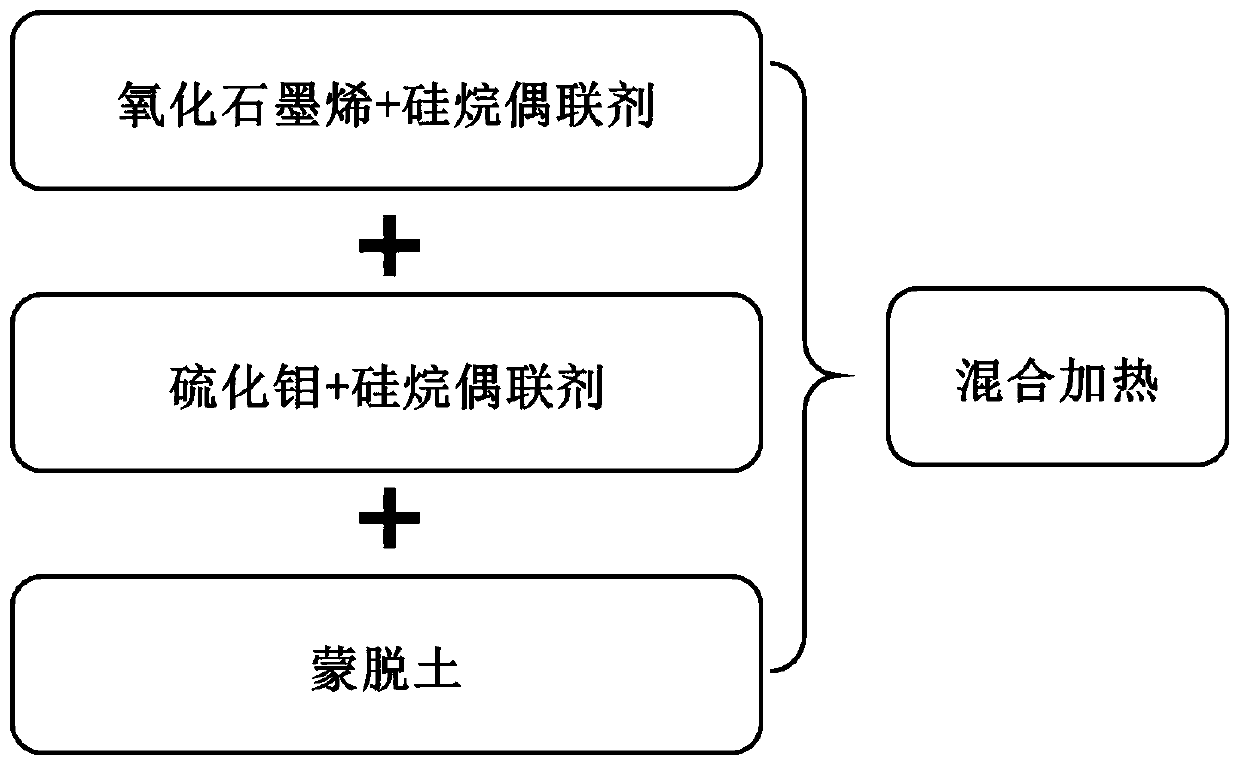

Method used

Image

Examples

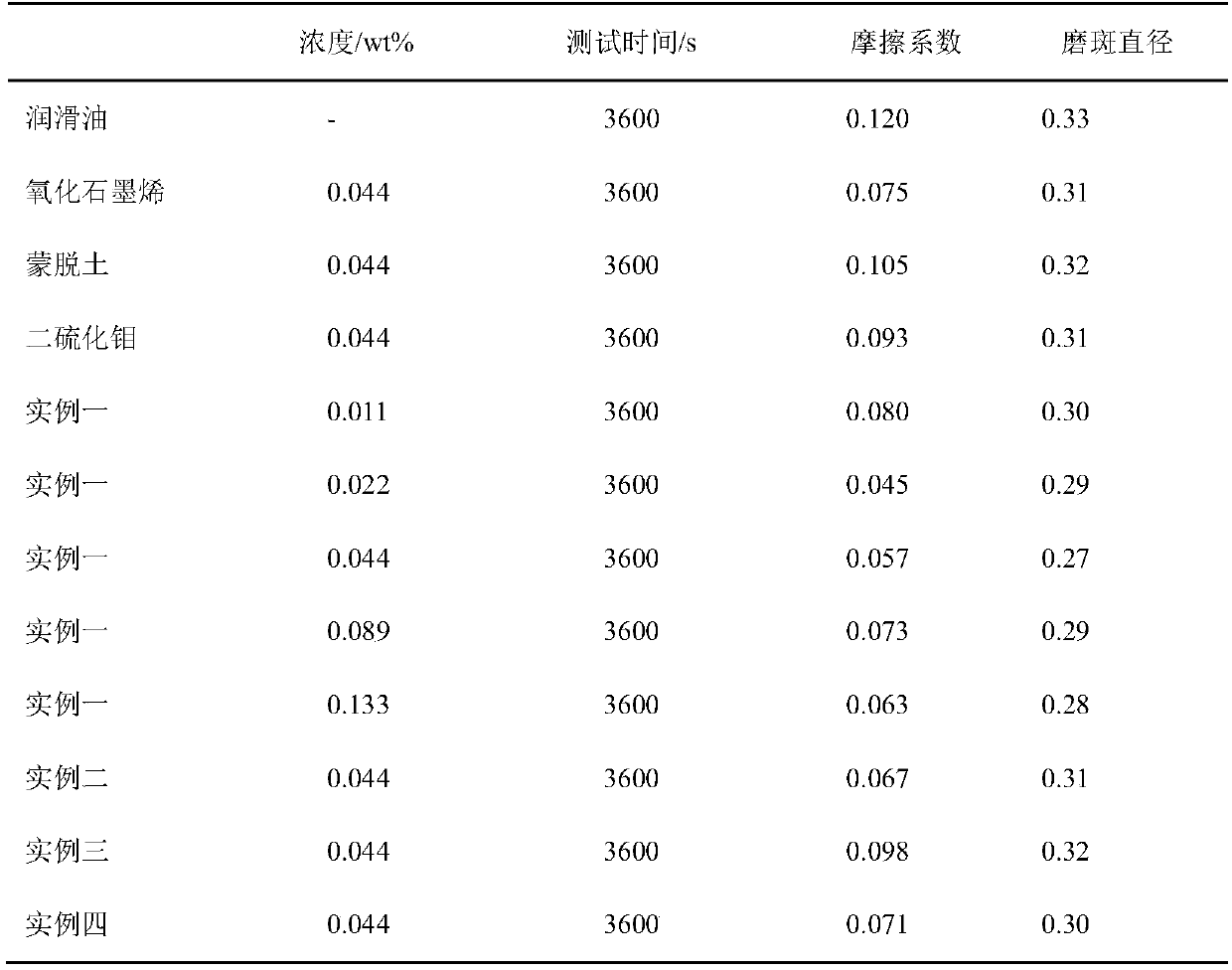

Embodiment 1

[0025] (1) First, 160 g of an aqueous dispersion of graphene oxide having a concentration of 0.025 wt % was prepared. Then, 6 mL of silane coupling agent (A-1100) was added, and magnetically stirred at room temperature for 1 h. Finally, it was transferred to a flask and reacted in a water bath at 80°C for 2h. After separation and cleaning, an appropriate amount of deionized water is added to obtain an aqueous dispersion of functional graphene oxide.

[0026] (2) Weigh 0.04g of molybdenum sulfide and add water and stir evenly to obtain an aqueous dispersion of molybdenum sulfide, add 6mL of silane coupling agent (A-1100) and stir at room temperature for 1h, heat at 80°C for 2h, separate and wash to obtain modified vulcanization molybdenum.

[0027] (3) Take the above-mentioned modified molybdenum sulfide, 0.16g of montmorillonite and the above-mentioned functional graphene oxide aqueous dispersion and mix and stir for 1h; transfer to the reaction kettle for 4h of hydrothermal...

Embodiment 2

[0031] (1) First, 160 g of an aqueous dispersion of graphene oxide having a concentration of 0.025 wt % was prepared. Then, 1 mL of silane coupling agent (A-1110) was added and reacted at 25° C. for 5 h. After separation and cleaning, an appropriate amount of deionized water is added to obtain an aqueous dispersion of functional graphene oxide.

[0032] (2) Weigh 0.01 g of molybdenum sulfide, add water and stir evenly to obtain an aqueous dispersion of molybdenum sulfide, add 0.5 mL of silane coupling agent (A-1110) to react at 25° C. for 8 hours, separate and wash to obtain modified molybdenum sulfide.

[0033] (3) Mix and stir the aqueous dispersion of the above-mentioned modified molybdenum sulfide, 0.02g montmorillonite and the above-mentioned functional graphene oxide for 0.5h; transfer to an autoclave for 200°C hydrothermal reaction for 1h, let it stand for cooling; separate, wash, Dry to obtain functional graphene / montmorillonite / modified molybdenum sulfide composite l...

Embodiment 3

[0037] (1) First, 160 g of an ethanol dispersion of graphene oxide having a concentration of 0.025 wt % was prepared. Then, 8 mL of silane coupling agent (A-1120) was added, and the mixture was refluxed at 80° C. for 1 h. After separation and cleaning, an appropriate amount of ethanol is added to obtain an ethanol dispersion of functional graphene oxide.

[0038] (2) Weigh 0.16g of molybdenum sulfide and add ethanol and stir evenly to obtain ethanol dispersion of molybdenum sulfide, add 16mL of silane coupling agent (A-1120) to react at 60°C for 3h, separate and wash to obtain modified molybdenum sulfide.

[0039] (3) Take the above-mentioned modified molybdenum sulfide, 0.32g montmorillonite and the ethanol dispersion of the above-mentioned functional graphene oxide and mix and stir for 2h; transfer to a flask and heat at reflux for 5h at 100°C, let stand and cool; separate, wash, and dry to obtain Functional graphene / montmorillonite / modified molybdenum sulfide composite lub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com