Amorphous alloy component and preparation method thereof

A technology of amorphous alloy and amorphous master alloy, applied in the field of preparation of amorphous alloy, can solve the problems of unstable performance, high cost of amorphous alloy, lack of alloy preparation equipment, etc., and achieves good mold filling and high surface finish. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] In the specific implementation process, the preparation method of a kind of amorphous alloy member proposed by the present invention comprises:

[0026] (1) Alloying the metal raw materials of each component (such as: zirconium-based raw materials) according to the design ratio to obtain an amorphous master alloy, and processing the amorphous master alloy into a size suitable for die-casting;

[0027] (2) Vacuum die-casting the amorphous master alloy: place the amorphous master alloy in a quartz or calcium oxide crucible, and vacuumize the closed environment where the crucible is located, and heat and melt the amorphous master alloy after reaching a suitable vacuum degree alloy, by adjusting the melting temperature, setting the injection speed and controlling the injection pressure to determine the vacuum die-casting conditions, pour the amorphous master alloy melt into the barrel quickly, and melt the amorphous master alloy under the vacuum die-casting conditions After...

Embodiment 1

[0032] In this embodiment, the grade of the amorphous alloy is: Zr-Y 0.8 , the preparation method of the amorphous alloy component is as follows:

[0033] (1) Alloying each component metal raw material zirconium, copper, nickel, aluminum, silver, and rare earth yttrium to obtain an amorphous master alloy, and processing the amorphous master alloy into a size suitable for die-casting;

[0034] (2) Vacuum die-casting the amorphous master alloy: place the amorphous master alloy in a quartz or calcium oxide crucible, and vacuumize the closed environment where the crucible, feeding barrel and mold are located to reach a suitable vacuum degree Then heat and melt the amorphous master alloy, heat the melt temperature of the amorphous master alloy to 950°C, quickly pour it into the barrel, and inject it into the watch case mold at a speed of 0.4m / s and a pressure of 6MPa to obtain an amorphous Alloy watch case.

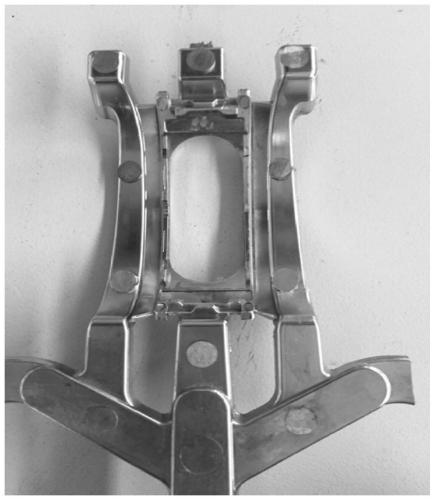

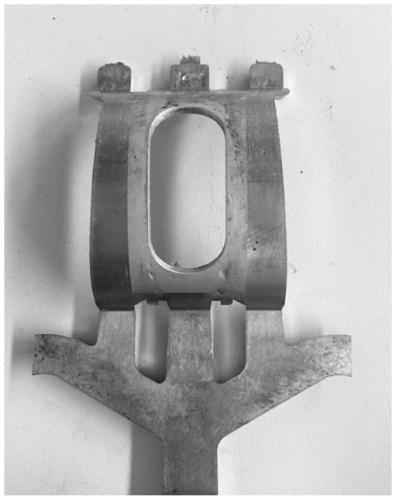

[0035] Such as figure 1 As shown, the amorphous alloy member in Exampl...

Embodiment 2

[0052] In this embodiment, the grade of the amorphous alloy is: Zr-Y 0.8 , the preparation method of the amorphous alloy component is as follows:

[0053] (1) Alloying zirconium, copper, nickel, and rare earth yttrium to obtain an amorphous master alloy, and processing the amorphous master alloy into a size suitable for die-casting;

[0054] (2) Vacuum die-casting the amorphous master alloy: placing the amorphous master alloy in a crucible, and vacuumizing the closed environment where the crucible, feeding barrel and mold are located and heating to 980°C to form a melt, The melt is poured into a barrel, and injected into a mold at a speed of 0.5 m / s and a pressure of 8 MPa to obtain an amorphous alloy component.

[0055] The yield of the amorphous alloy member of Example 2 was 91%, and the compressive strength was 1700 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com