A kind of preparation method of manganese dioxide-conductive polypropylene composite anode plate

A technology of manganese dioxide and composite anode, which is applied in the direction of electrodes, electrolytic components, electrolytic process, etc., can solve the problems such as the quality reduction of cathode zinc products, and achieve the effects of good connection, low oxygen evolution potential, and improved conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A preparation method of a manganese dioxide-conductive polypropylene composite anode plate, specifically implemented according to the following steps:

[0032] Step 1. Measure the following raw materials by volume percentage: 10% of carbon black with a particle size of 0.5mm, 0.1% of copper powder with a particle size of 50 mesh, and the balance being polypropylene powder with a particle size of 50 mesh.

[0033] Step 2. Fully grind the carbon black measured in step 1, fully mix it with copper powder and polypropylene powder to obtain a mixed powder, and evenly spread the mixed powder on the preheated and sprayed with silicone oil release agent on both sides of the ceramic plate In between, when spraying the silicone oil release agent, it is 30cm away from the ceramic plate, so that it is a uniformly covered thin layer, and the thickness of the mixed powder is 5mm. Counterweight, press for 5 minutes, and cool to room temperature to obtain a conductive polyethylene sheet...

Embodiment 2

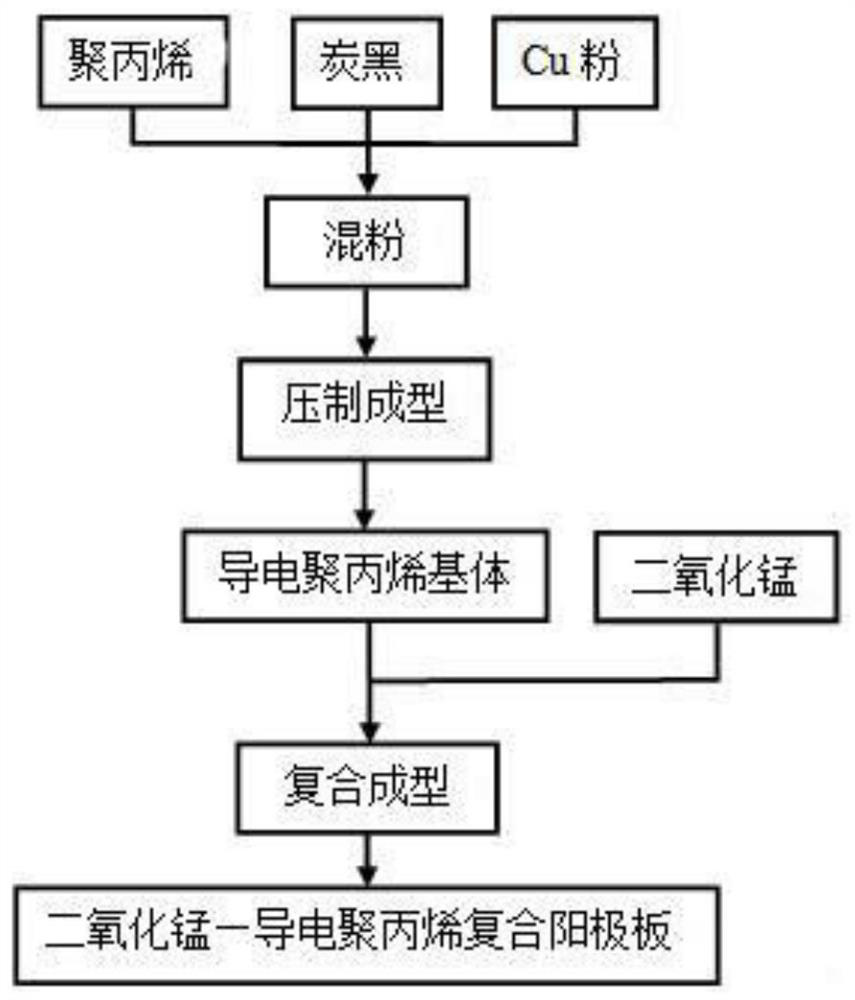

[0036] A kind of preparation method of manganese dioxide-conductive polypropylene composite anode plate, such as figure 1 As shown, the specific steps are as follows:

[0037] Step 1. Measure the following raw materials by volume percentage: 25% of carbon black with a particle size of 2mm, 0.5% of copper powder with a particle size of 100 mesh, and the balance being polypropylene powder with a particle size of 100 mesh.

[0038] Step 2. Fully grind the carbon black measured in step 1, fully mix it with copper powder and polypropylene powder to obtain a mixed powder, and spread the mixed powder evenly on the preheated and sprayed with silicone oil release agent on both sides of the ceramic plate In between, when spraying the silicone oil release agent, it is 35cm away from the ceramic plate, so that it is a uniformly covered thin layer, and the thickness of the mixed powder is 7mm. Counterweight, press for 15 minutes, and cool to room temperature to obtain a conductive polyeth...

Embodiment 3

[0041] A kind of preparation method of manganese dioxide-conductive polypropylene composite anode plate of the present invention, specifically implement according to the following steps:

[0042]Step 1. Measure the following raw materials by volume percentage: 40% of carbon black with a particle size of 3mm, 1% of copper powder with a particle size of 200 mesh, and the balance being polypropylene powder with a particle size of 200 mesh.

[0043] Step 2. Fully grind the carbon black measured in step 1, fully mix it with copper powder and polypropylene powder to obtain a mixed powder, and evenly spread the mixed powder on the preheated and sprayed with silicone oil release agent on both sides of the ceramic plate In between, when spraying the silicone oil release agent, it is 40cm away from the ceramic plate, so that it is a uniformly covered thin layer, and the thickness of the mixed powder is 9mm. Counterweight, press for 30 minutes, and cool to room temperature to obtain a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com