A kind of lithium salt additive and its lithium ion battery non-aqueous electrolyte

A lithium-ion battery and non-aqueous electrolyte technology, applied in the field of lithium-ion batteries, can solve the problems of LiFSI corroding aluminum foil, difficulty in balancing high and low temperature performance, and short high-temperature cycle life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

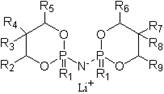

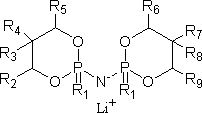

Method used

Image

Examples

Embodiment 1

[0024] (1) Preparation of electrolyte:

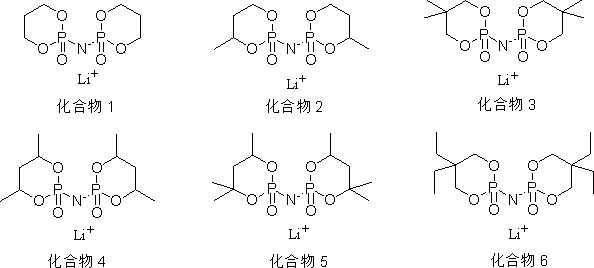

[0025] Under argon atmosphere, the electrolyte is prepared in a vacuum glove box with a moisture content of 6 The concentration of lithium salt is 1.0mol / L, the content of PS is 2% of the total weight of the electrolyte, the content of lithium difluorophosphate is 1% of the total weight of the electrolyte, and the bimolecular phosphoric acid amide lithium salt added with 1% by weight is named as Compound 1 was uniformly mixed to obtain the lithium ion electrolyte solution of the present invention.

[0026] (2) Preparation of positive electrode sheet: Li[Ni 0.5 mn 0.2 co 0.3 ]O 2 : PVDF:SP=95:1:4 Mix evenly with 1-methyl-2-pyrrolidone, coat the mixed slurry on both sides of the aluminum foil, dry and roll to obtain the positive electrode sheet.

[0027] (3) Preparation of negative pole piece: Dissolve graphite: SP: CMC: SBR=95:1.5:1.0:2.5 in aqueous solution, mix evenly, coat both sides of copper foil with the mixed slurry, and dry ...

Embodiment 2~9 and comparative example 1

[0034] This embodiment is used to illustrate the lithium-ion battery non-aqueous electrolyte disclosed by the present invention and its preparation method, including most of the operating steps in Example 1, the difference being:

[0035] In the preparation step of the non-aqueous electrolytic solution, the non-aqueous electrolytic solution is added with the components shown in the mass percentages of Examples 2-9 or Comparative Example 1 in Table 1.

[0036] The specific test method is consistent with that of Example 1, and the test results are shown in Table 2.

[0037] The electrolyte composition of table 1 embodiment and comparative example

[0038] main solvent additive lithium salt Example 1 EC:EMC:DEC=2:5:3 PS 2%; LiPO 2 f 2 1%; Compound 1 1%

1.0mol / L Example 2 EC:EMC:DEC=2:5:3 PS 2%; LiPO 2 f 2 1%; Compound 2 1%

1.0mol / L Example 3 EC:EMC:DEC=2:5:3 PS 2%; LiPO 2 f 2 1%; compound 3 1%

1.0mol / L Exam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com