High efficiency renewable adsorption light-catalyzed reaction module for removing VOCs and working method of high efficiency renewable adsorption light-catalyzed reaction module

A photocatalytic reaction and high-efficiency technology, applied in the field of air purification, can solve the problems of long regeneration time of adsorbent, easy deactivation of adsorbent, low photocatalytic efficiency, etc., to reduce competitive adsorption, increase photocatalytic activity, and prolong deactivation. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

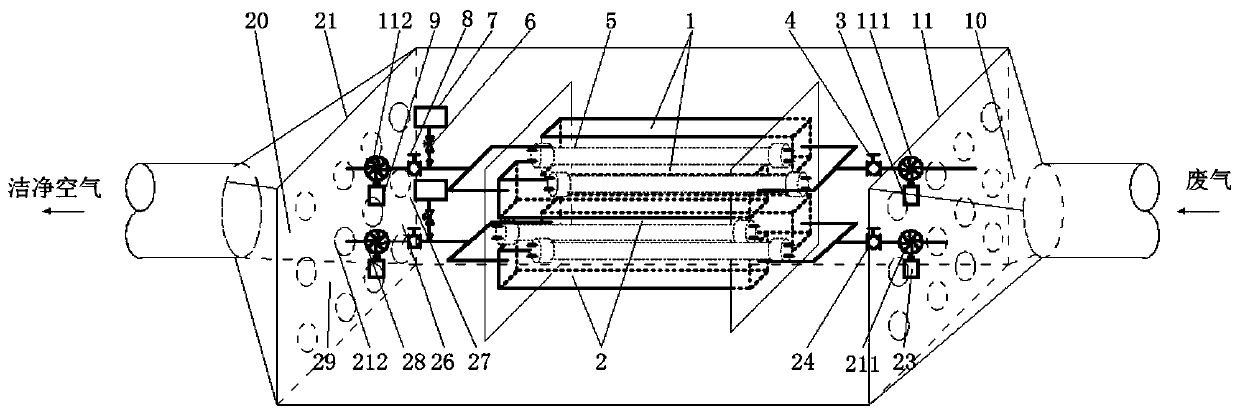

[0033] Such as figure 1 As shown, an efficient and reproducible adsorption photocatalytic reaction module for the removal of VOCs,

[0034] 1. The two sets of purification units are composed of two square reactors made of quartz glass, and the reactors are filled with nano-TiO 2 A total of four 254nm ultraviolet lamp tubes are installed between each square reactor;

[0035] 2. The air with a formaldehyde content of 1.0ppm is passed into the reaction module at a flow rate of 5mL / min; the first air inlet negative pressure device control unit 3 controls the first air inlet negative pressure device 111 to open, and the second air inlet negative pressure device 111 is opened. The pressure device control unit 23 controls the negative pressure device 211 at the second air intake end to close, and the waste gas enters the first purification unit. Under the synergistic effect of adsorption and photocatalysis, the formaldehyde removal rate is above 90%, the first regulating valve 6 is ...

Embodiment 2

[0039] An Efficient and Renewable Adsorption Photocatalytic Reaction Module for VOCs Removal

[0040] 1. Increase the two sets of purification units in Example 1 to four square reactors made of ordinary glass, and the reactor is filled with nano-TiO 2 Coal-based activated carbon, a total of 10 365nm ultraviolet lamp tubes are installed between each square reactor,

[0041] 2. Pass air with a formaldehyde content of 1.0ppm into the reaction module at a flow rate of 5mL / min, run the entire high-efficiency regenerative adsorption photocatalytic reaction module according to the operation mode of Example 1, and the formaldehyde removal rate is above 95%. The catalyst and adsorbent The regeneration effect is good, and it can run continuously for a long time.

Embodiment 3

[0043] An Efficient and Renewable Adsorption Photocatalytic Reaction Module for VOCs Removal

[0044] 1. The arrangement of the square reactor of the purification unit and the ultraviolet lamp in the reaction module is the same as that of Example 2, and the square reactor is filled with nano-TiO 2 zeolite molecular sieves.

[0045] 2. Pass a mixed gas containing 100 ppm of benzene, toluene and xylene into the reaction module at a flow rate of 5 mL / min. When the first purification unit performs the purification function, the module operates in the same manner as Example 1, and the removal rate of benzene, toluene and xylene is above 95%;

[0046] 3. After running for a period of time, the second purification unit performs the gas purification function, and the operation mode is the same as that of Example 1; at this time, the first purification unit performs regeneration of the adsorbent and photocatalysis, and the first air inlet negative pressure device control unit 3 Contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com