Sizing agent for reducing graphene oxide according to preset pattern, application method and obtained graphene film layer

A predetermined pattern, graphene film technology, applied in the direction of graphene, nano carbon, etc., can solve the problems of harsh environment, unsuitability, photoresist toxicity, etc., to achieve the effect of complete pattern and clear edge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

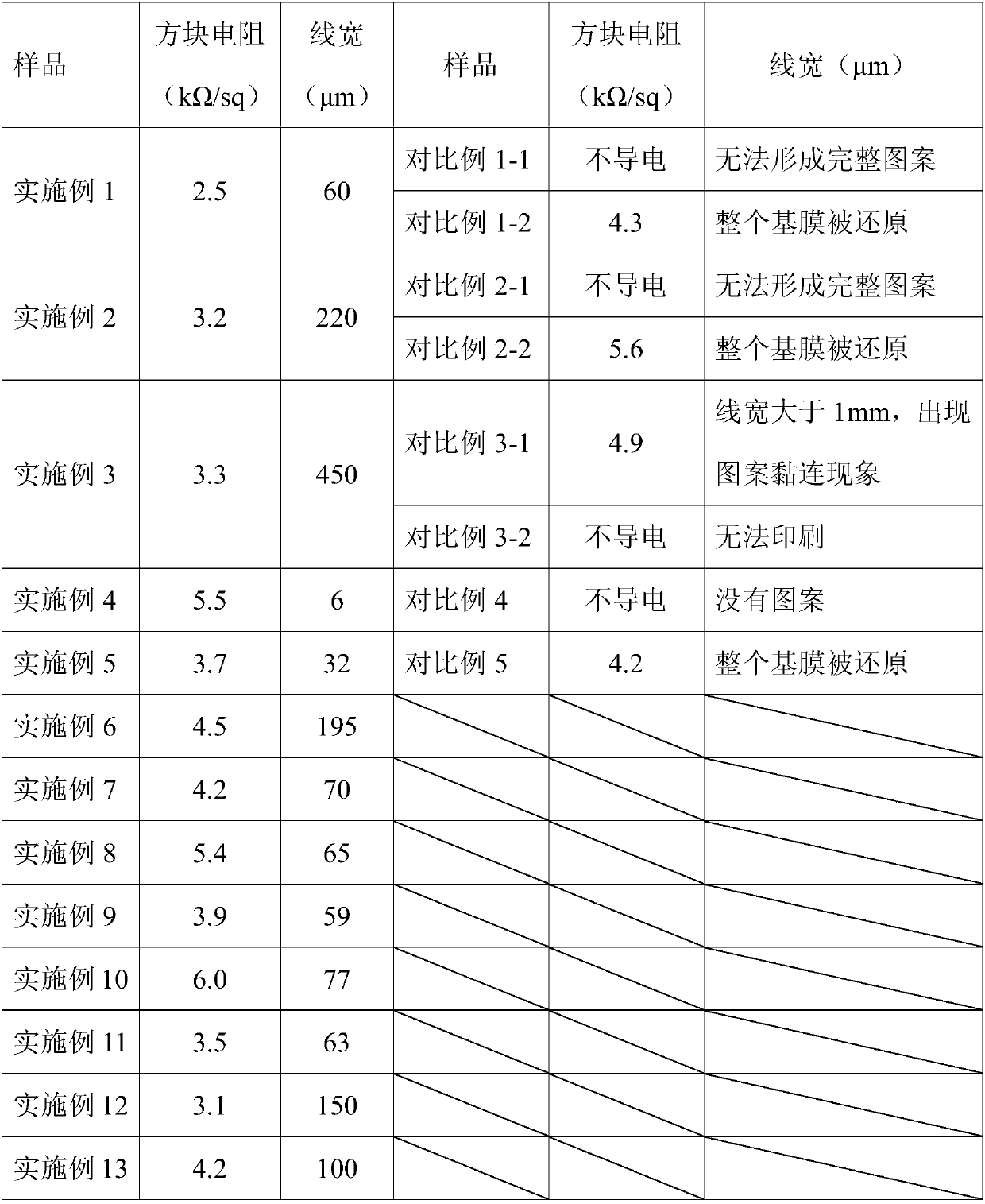

Embodiment 1

[0053] A method for preparing a patterned graphene film includes the following steps:

[0054] (1) Prepare a 10nm thick graphene oxide film on the surface of the PET film by spin coating;

[0055] (2) A slurry was prepared in a proportion of 50% by weight of aluminum powder (particle size of 10μm), 10% by weight of polyester resin (weight average molecular weight greater than 100,000), and 40% by weight of N-methylpyrrolidone, and the viscosity of the slurry was measured Is 1000 centipoise;

[0056] (3) Apply the slurry of step (2) to the surface of the graphene oxide film prepared in step (1) by screen printing, with a line width of 50 μm;

[0057] (4) Let stand for 1 min at a temperature of 50°C, dry for 5 min, pickle for 1 min, water for 2 min, and dry for 1 min. Finally, the graphene patterned film has a line width of 60 μm, clear edges, and complete graphene film. The thickness of the graphene patterned film was measured to be about 10 nm.

Embodiment 2

[0065] A method for preparing a patterned graphene film includes the following steps:

[0066] (1) Prepare a 1μm thick graphene oxide film on the surface of the PET film by dipping;

[0067] (2) According to the ratio of zinc powder (particle size of 2μm) 30wt%, polyurethane (weight average molecular weight of 250,000) 5wt%, DMF (N,N-dimethylformamide) 65wt%, the measured viscosity is 800 centipoise;

[0068] (3) Apply the slurry of step (2) to the surface of the graphene oxide film prepared in step (1) by screen printing, with a line width of 200 μm;

[0069] (4) Let stand for 5 minutes at a temperature of 30°C, dry for 5 minutes, pickle for 1 minute, wash for 2 minutes, and dry for 10 minutes. The final graphene patterned film has a line width of 220 μm, clear edges, and complete graphene film. The thickness of the graphene patterned film was measured to be about 1 μm.

Embodiment 3

[0077] A method for preparing a patterned graphene film includes the following steps:

[0078] (1) Prepare a 10μm thick graphene oxide film on the surface of the PP film by extrusion coating;

[0079] (2) According to the proportion of 30wt% of stannous chloride, 15wt% of PVP (polyvinylpyrrolidone) (weight average molecular weight of 150,000), and 55wt% of DMSO (dimethyl sulfoxide), the measured viscosity is 400%. Moor

[0080] (3) Apply the slurry of step (2) to the surface of the graphene oxide film prepared in step (1) by using gravure printing, with a line width of 500 μm;

[0081] (4) Let stand for 10 minutes at a temperature of 40°C, dry for 10 minutes, pickle for 5 minutes, water for 5 minutes, and dry for 15 minutes. The final graphene patterned film has a line width of 450 μm, clear edges and complete graphene film. The thickness of the graphene patterned film was measured to be 9.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com