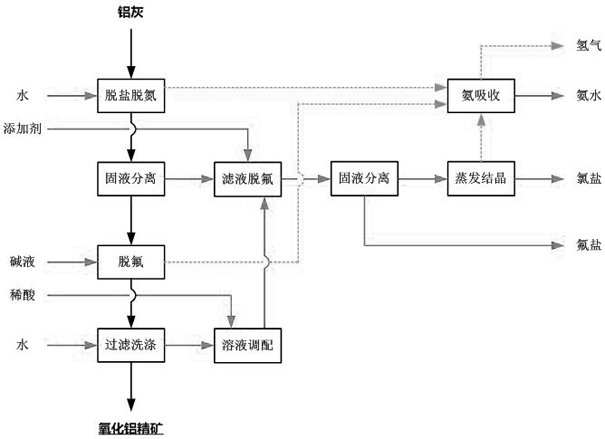

A method for efficiently separating fluorine, chlorine, and nitrogen components from aluminum ash to co-produce alumina concentrate

A technology of alumina and aluminum ash, applied in aluminate/alumina/aluminum hydroxide purification, ammonium chloride, alkali metal chloride, etc., to achieve efficient separation and recycling, low investment, and high-efficiency separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

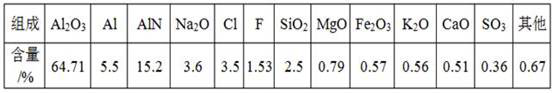

[0038] In this embodiment, the method for efficiently separating fluorine, chlorine, and nitrogen components from aluminum ash to co-produce alumina concentrate, the specific steps are as follows:

[0039] (1) Desalination and denitrification: Weigh the secondary aluminum ash from an enterprise in Gongyi and put it into the reactor, add water as a solvent according to the ratio of liquid to solid ratio of 2; turn on the stirring and heating control device of the reactor, at 75 Stir at high speed for 2 hours at a temperature of ℃, and the gas generated during the reaction is introduced into the gas absorption device through the pipeline;

[0040] (2) Solid-liquid separation: After the reaction is completed, the slurry is released, and the solid-liquid two-phase is separated by suction filtration;

[0041] (3) Defluorination: Add the separated solid phase and lye with a concentration of 150g / L into the reaction kettle at a ratio of liquid to solid ratio of 2, mix thoroughly, and...

Embodiment 2

[0050] In this embodiment, the method for efficiently separating fluorine, chlorine, and nitrogen components from aluminum ash to co-produce alumina concentrate, the specific steps are as follows:

[0051] (1) Desalination and denitrification: add aluminum ash and water to the reactor according to the ratio of liquid to solid ratio of 1.5, turn on the stirring and heating control device of the reactor, and stir at a high speed for 4 hours at a temperature of 25°C. The gas is introduced into the gas absorption device through the pipeline;

[0052] (2) Solid-liquid separation: After the reaction is completed, the slurry is released, and the solid-liquid two-phase is separated by means of pressure filtration;

[0053] (3) Defluorination: Add the separated solid phase and lye with a concentration of 200g / L into the reaction kettle at a liquid-solid ratio of 1.5, mix well, and react at room temperature of 25°C for 4 hours , the gas produced in the reaction process is introduced in...

Embodiment 3

[0062] In this embodiment, the method for efficiently separating fluorine, chlorine, and nitrogen components from aluminum ash to co-produce alumina concentrate, the specific steps are as follows:

[0063] (1) Desalination and denitrification: Weigh the secondary aluminum ash from an enterprise in Gongyi and put it into the reactor, add water as a solvent according to the ratio of liquid to solid ratio of 2; turn on the stirring and heating control device of the reactor, at 50 Stir at high speed for 3 hours at a temperature of ℃, and the gas generated during the reaction is introduced into the gas absorption device through the pipeline;

[0064] (2) Solid-liquid separation: After the reaction is completed, the slurry is released, and the solid-liquid two-phase is separated by suction filtration;

[0065] (3) Defluorination: Add the separated solid phase and lye with a concentration of 200g / L into the reaction kettle at a liquid-solid ratio of 2, mix well, and then keep warm at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com