Adipic acid particle screening device and method for screening and improving quality of dried adipic acid product by using same

A screening device and adipic acid technology, applied in the direction of granular material drying, cyclone device, drying solid materials, etc., can solve the problems of improving the production process of adipic acid without drying adipic acid particle size screening, and achieve increased fluidity, The effect of uniform particle size and product quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

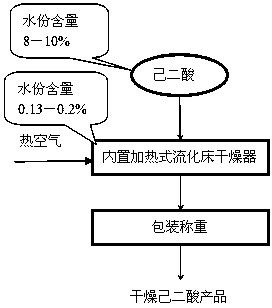

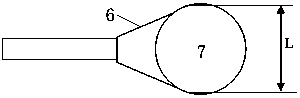

[0025] A particle size screening device for adipic acid, such as figure 2 with image 3 As shown, it includes a fluidized bed dryer 3, a large silo 1, a nitrogen source 4, an air homogenizer 6, a winnowing chamber 7, a cyclone 8 and a packaging and weighing device. The winnowing chamber 7 is equipped with gas inlets, materials The inlet, the outlet of the winnowing material and the outlet of the large-size material. The fluidized bed dryer 3 is connected to the top inlet of the large silo 1 through a tube chain conveyor, and the bottom outlet of the large silo 1 is connected to the material inlet of the air separation chamber 7 through a pipe. The source 4 is connected to the inlet of the homogenizer 6 through a pipe, the outlet of the homogenizer 6 is connected to the gas inlet of the winnowing chamber 7, and the outlet of the winnowing material is connected to the inlet of the cyclone 8 through a pipe. The cyclone 8 is provided with dust The outlet is connected to the outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com