Fluorescent glass ceramic material and light-emitting device containing same

A technology of ceramic materials and fluorescent glass, which is applied in the direction of luminescent materials, chemical instruments and methods, semiconductor devices, etc., can solve the problems of low luminous efficiency and poor stability, and achieve high luminous efficiency, high stability, excellent thermal stability and The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the fluorescent glass-ceramic material described in the present invention can be prepared by existing conventional methods. In the embodiment of the present invention, the various raw materials required for the above-mentioned fluorescent glass-ceramic material are uniformly mixed, and then pressed into tablets and calcined. , the calcination environment can be air or nitrogen, hydrogen, CO gas protected furnace body, according to a certain program, heat up at the highest temperature for 0.5-10 hours, then take it out after cooling, and carry out grinding, pickling, polishing, cutting, etc. post-processing steps within.

[0030] In yet another typical embodiment of the present invention, a light-emitting device is provided, including a light source and a fluorescent glass-ceramic material, the fluorescent glass-ceramic material is the above-mentioned fluorescent glass-ceramic material, and the light source includes a laser, a high-power LED, an ...

Embodiment 1-5

[0033] According to the type and quality of the glass-ceramic material and phosphor powder shown in Table 1-1 below, the glass-ceramic material and phosphor powder are mixed to form a mixture. Then the mixture is compressed into a tablet machine, placed in a high-temperature furnace for high-temperature treatment in an air atmosphere, and after cooling down, the sheet-shaped fluorescent glass-ceramic material is ground and polished to a desired thickness.

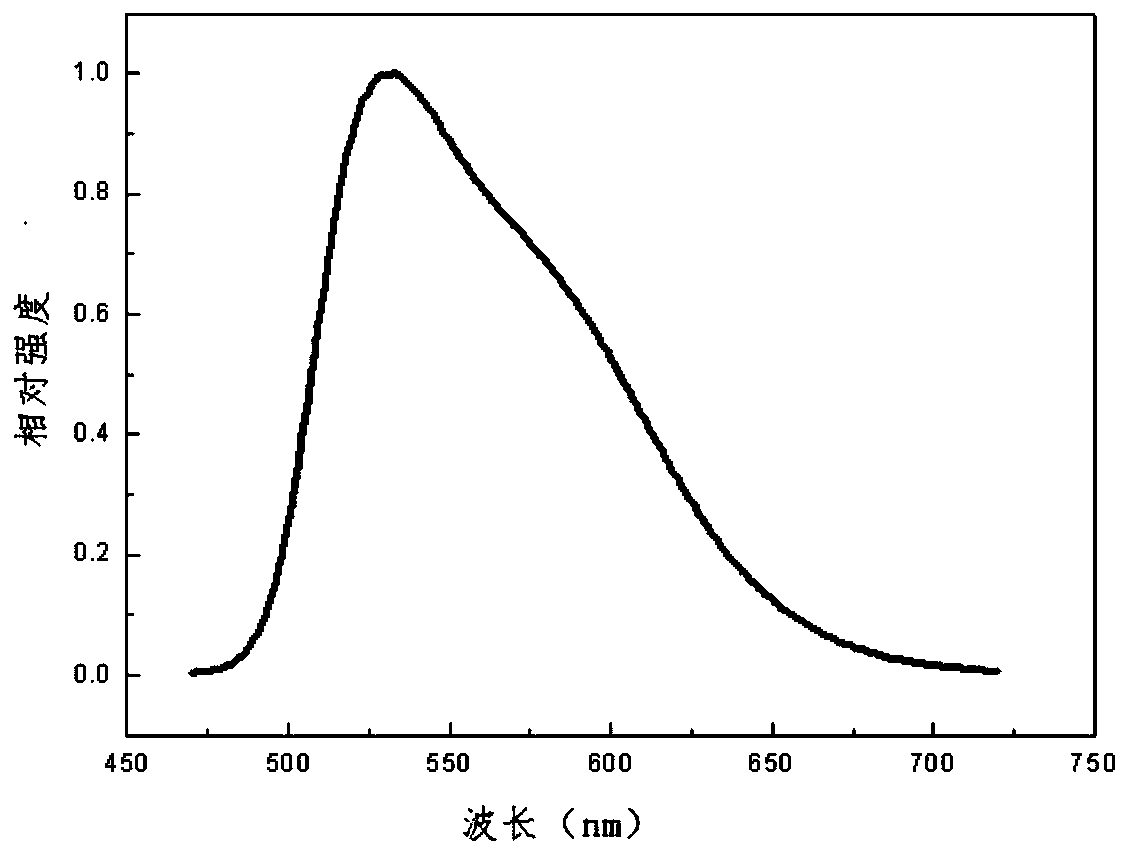

[0034] Fluorescence spectrum analysis is carried out to the fluorescent glass-ceramic material that embodiment 1 makes, as figure 1 As shown, it shows that the obtained fluorescent glass-ceramic material is different from the general commercial La 3 Si 6 N 11 :Ce fluorescence spectrum is roughly the same.

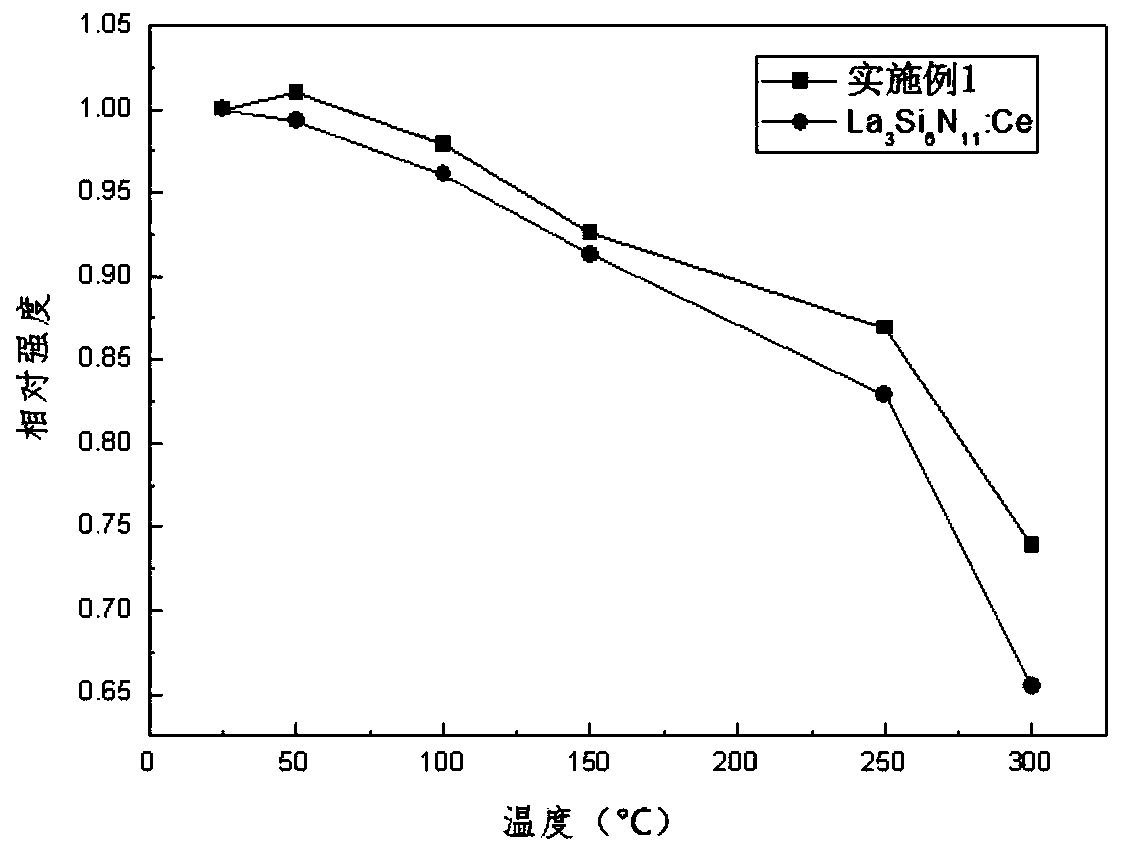

[0035] The thermal stability of the fluorescent glass-ceramic materials in Examples 1-5 above was tested, and the ratios of the luminous intensity at 150°C and 300°C to the luminous intensity at room temperature are s...

Embodiment 6-10

[0042] According to the composition and quality of the glass ceramic material and phosphor powder shown in Table 2-1 below, the glass ceramic material and phosphor powder are mixed to form a mixture. Then the mixture was compressed into a tablet machine, placed in a high-temperature furnace for high-temperature treatment in an air atmosphere, and after cooling down, the sheet-shaped fluorescent glass-ceramic material was ground and polished to the required thickness, and its thermal stability and transmission CIE were also tested. The results are shown in Table 2-2. and general commercial La 3 Si 6 N 11 : Compared with the thermal stability of Ce (91.1% at 150°C and 65.8% at 300°C), it has higher thermal stability.

[0043] table 2-1

[0044]

[0045] Table 2-2

[0046]

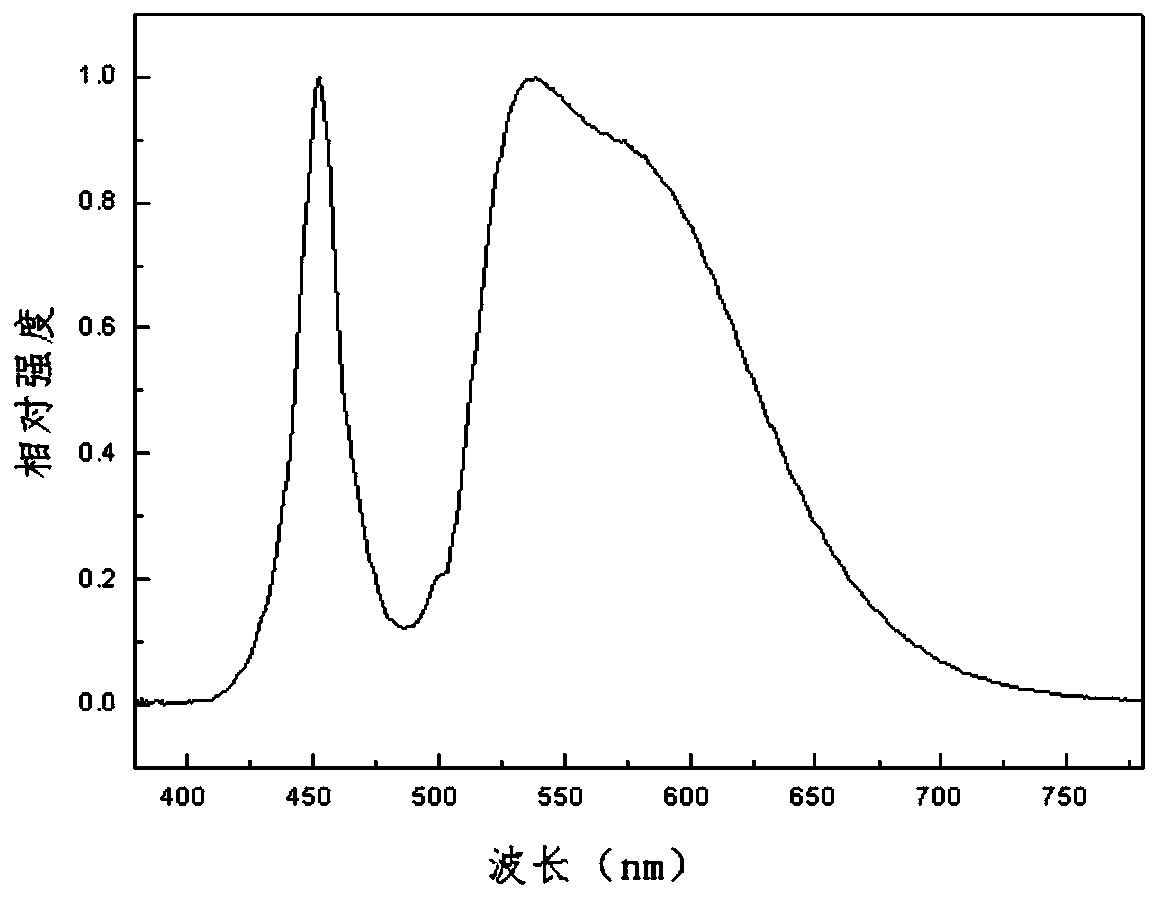

[0047] In summary, the fluorescent glass-ceramic material of the present invention has excellent luminescence performance and temperature characteristics, and can obtain continuous and stable spect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com