Preparation method of smokeless expandable graphite flame retardant

A technology of expanded graphite and flame retardant, which is applied in the field of flame retardant, can solve the problem of damage and shedding of the expanded carbon layer, achieve the effects of reduced smoke and dust, simple chemical structure, and no secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

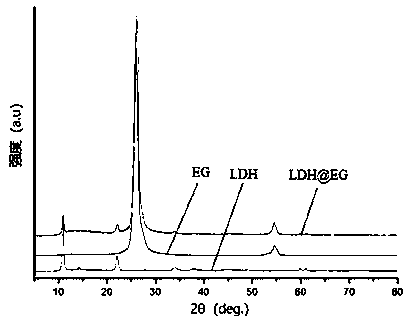

Embodiment 1

[0025] Add magnesium nitrate hexahydrate and aluminum nitrate nonahydrate into a 100mL beaker at a molar ratio of 3:1, add 50mL deionized water to fully dissolve to obtain solution S1; mix 2g of expandable graphite with a particle size of 50-150μm into solution S1 , mix evenly, adjust the pH value to 10 with sodium hydroxide solution, and stir well to obtain a mixed solution S2, wherein the mass ratio of expandable graphite to the coating material is 1:1; transfer the mixed solution S2 to 100mL polytetrafluoroethylene In an ethylene-lined autoclave, heat at 100°C for 12 hours by hydrothermal method, and cool to room temperature; the product obtained is centrifugally filtered with a centrifuge, washed with deionized water until the pH of the filtrate is neutral, and washed with ethanol The product was then dried at a temperature of 90 °C and cooled to room temperature to prepare a smokeless expandable graphite flame retardant (LDG@EG).

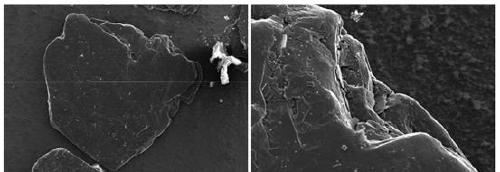

[0026] SEM images of expandable graphite...

Embodiment 2

[0029] Add magnesium nitrate hexahydrate and aluminum nitrate nonahydrate into a 100mL beaker at a molar ratio of 2:1, add 50mL deionized water to fully dissolve to obtain solution S1; mix 2g of expandable graphite with a particle size of 50-150μm into solution S1 , mix well, adjust the pH to 11 with sodium hydroxide solution, and stir well to obtain a mixed solution S2, wherein the mass ratio of expandable graphite to the coating material is 2:1; transfer the mixed solution S2 to 100mL polytetrafluoroethylene In a lined high-pressure reactor, heat preservation at 120°C for 18 hours by hydrothermal method, cool to room temperature; centrifuge filter to obtain the product; wash the product with deionized water until the pH value of the filtrate is neutral, wash with ethanol, and then in Dry at a temperature of 60°C and cool to room temperature to prepare a smokeless expandable graphite flame retardant.

[0030] According to the mass ratio of 1:3, the smokeless expandable graphi...

Embodiment 3

[0032] Add magnesium nitrate hexahydrate and aluminum nitrate nonahydrate into a 100mL beaker at a molar ratio of 4:1, add 50mL deionized water to fully dissolve to obtain solution S1; mix 2g of expandable graphite with a particle size of 50-150μm into solution S1 , mix evenly, adjust the pH to 10.5 with sodium hydroxide solution, and stir well to obtain a mixed solution S2, wherein the mass ratio of expandable graphite to the coating material (magnesium nitrate and aluminum nitrate) is 3:1; the mixed solution S2 Transfer to a 100mL polytetrafluoroethylene-lined autoclave, heat it at 80°C for 24 hours by hydrothermal method, cool to room temperature, and centrifugally filter to obtain the product; wash the product with deionized water until the pH value of the filtrate is neutral properties, washed with ethanol, dried at a temperature of 75°C, and cooled to room temperature to obtain a smokeless expandable graphite flame retardant.

[0033] According to the mass ratio of 1:3, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com