PE foamed wood-plastic board and production method thereof

A foamed material and board technology, which is applied in the fields of wood-plastic board and its preparation, PE foamed wood-plastic board and its preparation, can solve the problems of burning waste environment, easy aging and brittleness, short use time, etc. Forest resources, improve appearance quality, improve the effect of low temperature embrittlement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

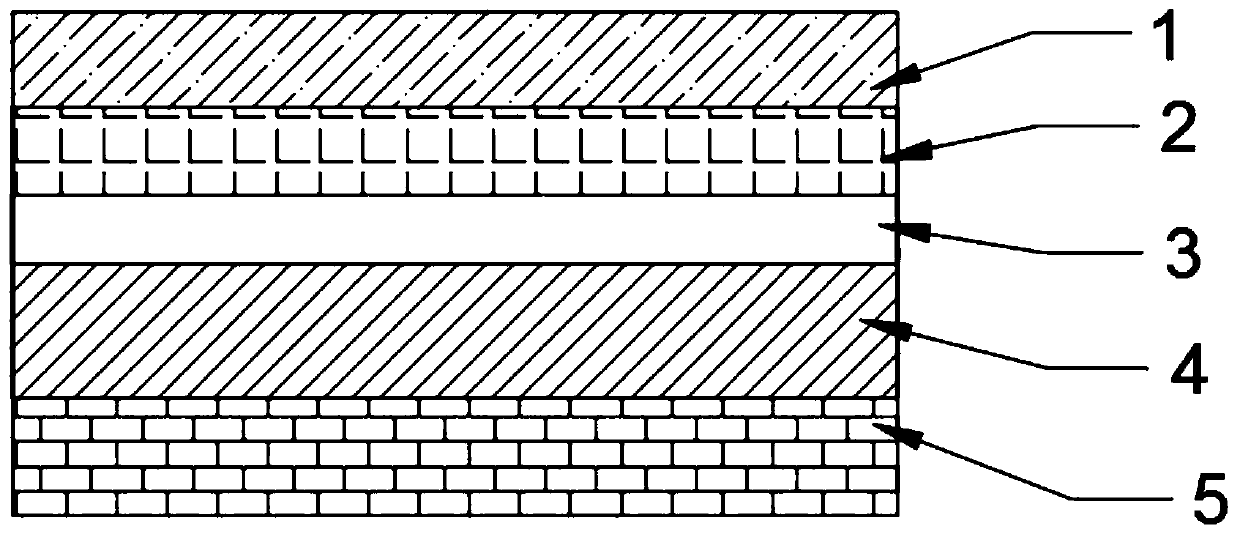

Image

Examples

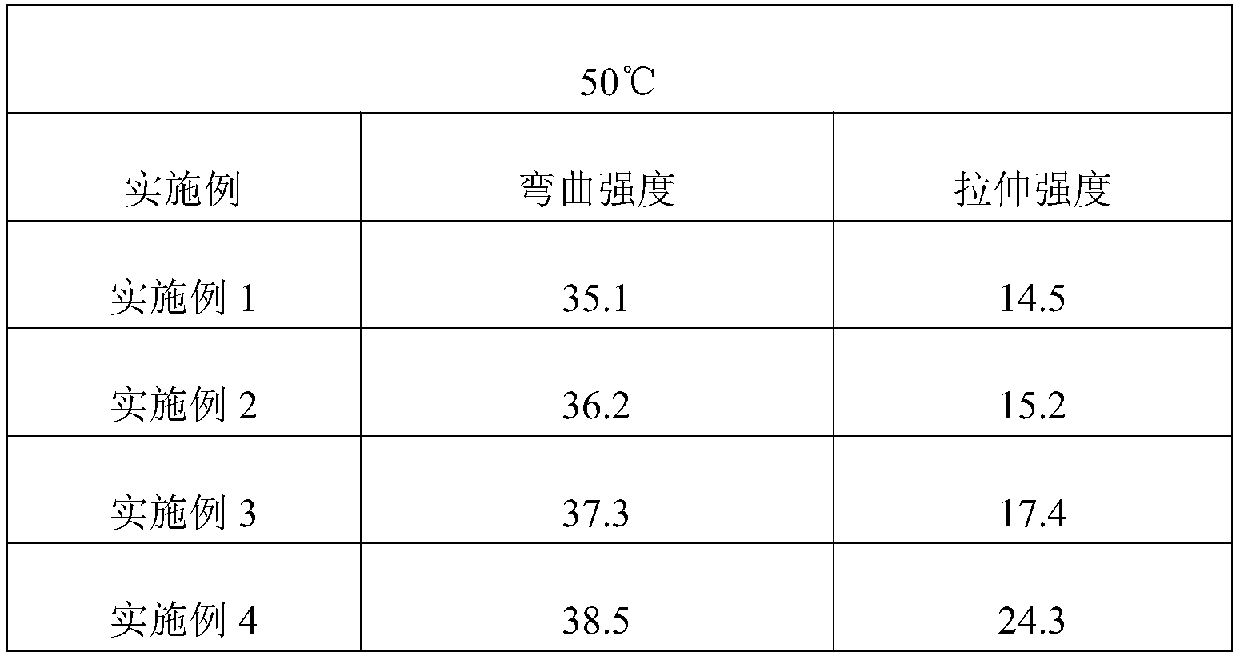

Embodiment 1

[0034] (1) Bake the cotton stalk powder at 132 degrees centigrade for 3 hours to make the moisture content below 3%.

[0035] (2) In parts by weight, take 30 parts of cotton straw powder, 40 parts of waste plastics, 5 parts of perlite, 10 parts of magnesium silicate, 3 parts of PE foam material, 4 parts of antioxidant, 5 parts of stabilizer, 30 parts of silicon dioxide, 1 part of impact modifier, 0.6 part of processing aid, 0.1 part of auxiliary stabilizer and 0.5 part of lubricant.

[0036] (3) According to processing step 1: add the above-mentioned raw materials into a high-speed mixer, and stir at a speed of 50-68r / min for 7-13min at room temperature;

[0037] Step 2: Stirring for 15-30min at 90-115°C and 68-120r / min to obtain a premix;

[0038] Step 3: Put the premixed material obtained in Step 2 into a kneader, melt it, and after cooling, crush it into granules or powders with a particle size below 1mm for use;

[0039] Step 4: The PE foamed wood-plastic board is obtained...

Embodiment 2

[0041] (1) Bake the cotton stalk powder at 132 degrees centigrade for 3 hours to make the moisture content below 3%.

[0042] (2) In parts by weight, 40 parts of cotton straw powder, 50 parts of waste plastics, 6 parts of perlite, 11 parts of magnesium silicate, 4 parts of PE foam material, 5 parts of antioxidant, 6 parts of stabilizer, 40 parts of silicon dioxide, 2 parts of impact modifier, 0.7 part of processing aid, 0.2 part of auxiliary stabilizer and 0.6 part of lubricant.

[0043] (3) According to processing step 1: add the above-mentioned raw materials into a high-speed mixer, and stir at a speed of 50-68r / min for 7-13min at room temperature;

[0044] Step 2: Stirring for 15-30min at 90-115°C and 68-120r / min to obtain a premix;

[0045] Step 3: Put the premixed material obtained in Step 2 into a kneader, melt it, and after cooling, crush it into granules or powders with a particle size below 1mm for use;

[0046] Step 4: The PE foamed wood-plastic board is obtained b...

Embodiment 3

[0048] (1) Bake the cotton stalk powder at 132 degrees centigrade for 3 hours to make the moisture content below 3%.

[0049] (2) In parts by weight, weigh 50 parts of cotton straw powder, 60 parts of waste plastics, 7 parts of perlite, 12 parts of magnesium silicate, 5 parts of PE foam material, 6 parts of antioxidant, 7 parts of stabilizer, 50 parts of silicon dioxide, 3 parts of impact modifier, 0.8 part of processing aid, 0.3 part of auxiliary stabilizer and 0.7 part of lubricant.

[0050] (3) According to processing step 1: add the above-mentioned raw materials into a high-speed mixer, and stir at a speed of 50-68r / min for 7-13min at room temperature;

[0051] Step 2: Stirring for 15-30min at 90-115°C and 68-120r / min to obtain a premix;

[0052] Step 3: Put the premixed material obtained in Step 2 into a kneader, melt it, and after cooling, crush it into granules or powders with a particle size below 1mm for use;

[0053] Step 4: The PE foamed wood-plastic board is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com