Nano functional coating and its preparation method and application

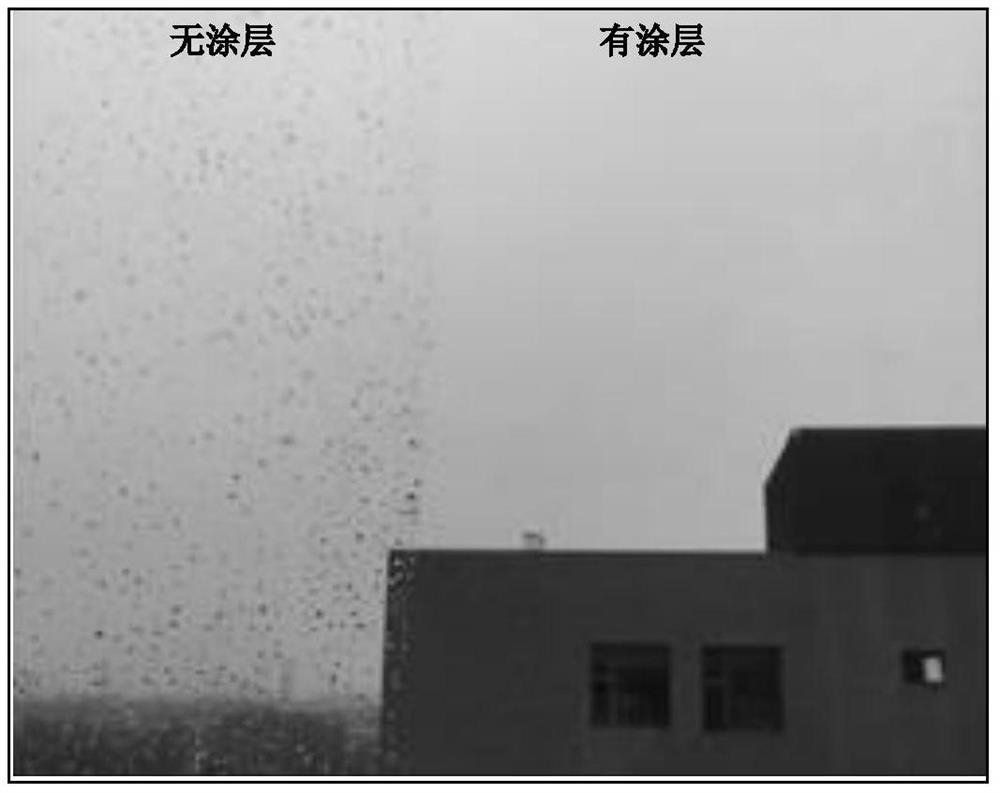

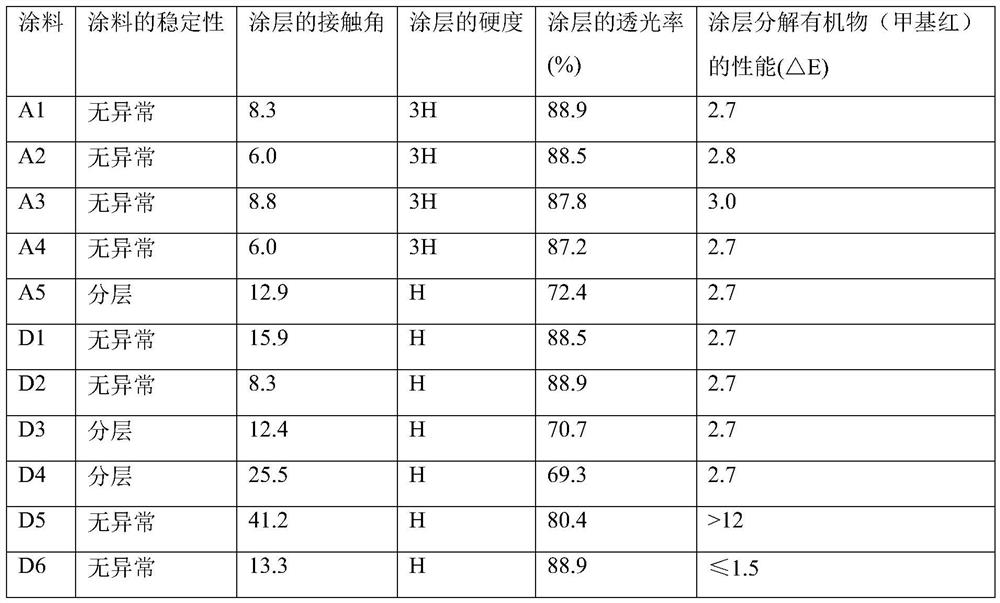

A nano-functional, coating technology, applied in conductive coatings, radiation-absorbing coatings, antifouling/underwater coatings, etc., can solve the problems of short curing time, poor light transmission, large contact angle, etc., and achieve short curing time , The effect of high light transmittance and small contact angle of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] In a first aspect, the present invention provides a method for preparing a nano-functional coating, comprising the following steps:

[0020] (1) mixing alcohol, silicate compound and organosilane modifier, and then under acidic conditions, mixing the resulting mixture with graphene and / or carbon nanotube dispersion and water to prepare an inorganic adhesive;

[0021] (2) under alkaline conditions, anatase nano-titanium dioxide powder, a dispersant and a dispersion medium are mixed to prepare a nano-titanium dioxide dispersion;

[0022] (3) mixing the inorganic adhesive obtained in step (1) with the nano-titanium dioxide dispersion obtained in step (2) to obtain a nano-functional coating;

[0023] Wherein, the organosilane modifier is selected from amino group-containing silane coupling agents.

[0024] In the method of the present invention, the selection of the organic alcohol in step (1) is not particularly limited, and can be conventionally selected in the field, as...

preparation Embodiment 1

[0061] (1) Mix and stir 84.50g absolute ethanol, 26.00g tetraethyl orthosilicate, and 29.25g N-β(aminoethyl)-γ-aminopropyltrimethoxysilane evenly, and rinse with hydrochloric acid (concentration is 36.5%) wt) to adjust the pH to 3, then slowly add 21.70g of water and 1g of graphene water dispersion with a mass fraction of 0.5% under stirring, and obtain a modified silica / graphene composite nano-inorganic adhesive after stirring and reacting. 50nm;

[0062] (2) Using water as the dispersion medium, stir and mix the anatase titanium dioxide nanopowder, dispersant and dispersion medium at a mass ratio of 1:0.004:5.7, and prepare by ultrasonic pulverization and dispersion at 50°C and pH=8 Nano-titanium dioxide aqueous dispersion, and further diluting the aqueous dispersion to obtain a concentration of 0.5% nano-titanium dioxide aqueous dispersion dilution;

[0063] (3) The modified silica / graphene composite nano-inorganic adhesive obtained in step (1) is slowly added to the nano-...

preparation Embodiment 2

[0065] (1) 75.00g of absolute ethanol, 23g of tetraethyl orthosilicate, and 25.88g of N-β (aminoethyl)-γ-aminopropyltrimethoxysilane were mixed and stirred evenly, and then mixed with hydrochloric acid (concentration is 36.5%wt) ) to adjust the pH to 2.5, then slowly add 20g of water and 3g of graphene dispersion with a mass fraction of 0.8% under stirring, and obtain a modified silica / graphene composite nano-inorganic adhesive after stirring and reacting, with a particle size of 30nm;

[0066] (2) Using water as the dispersion medium, stir and mix the anatase titanium dioxide nano-powder, dispersant and water at a mass ratio of 1:0.004:5.7, and use ultrasonic pulverization and dispersion at 60°C and pH=7 to prepare nano-particles Titanium dioxide aqueous dispersion, further diluting the aqueous dispersion to obtain a concentration of 0.8% nanometer titanium dioxide aqueous dispersion dilution;

[0067] (3) The modified silica / graphene composite nano-inorganic adhesive obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com