Potato coarse cereal pellet pancake based on fresh potato juice and preparation method thereof

A potato and juice technology, which is applied in the processing of dough, tuber baked goods, baking, etc., can solve the problem of difficult to balance potato skins, and achieve the effects of rich dietary fiber, slightly sweet taste, and rich processed products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

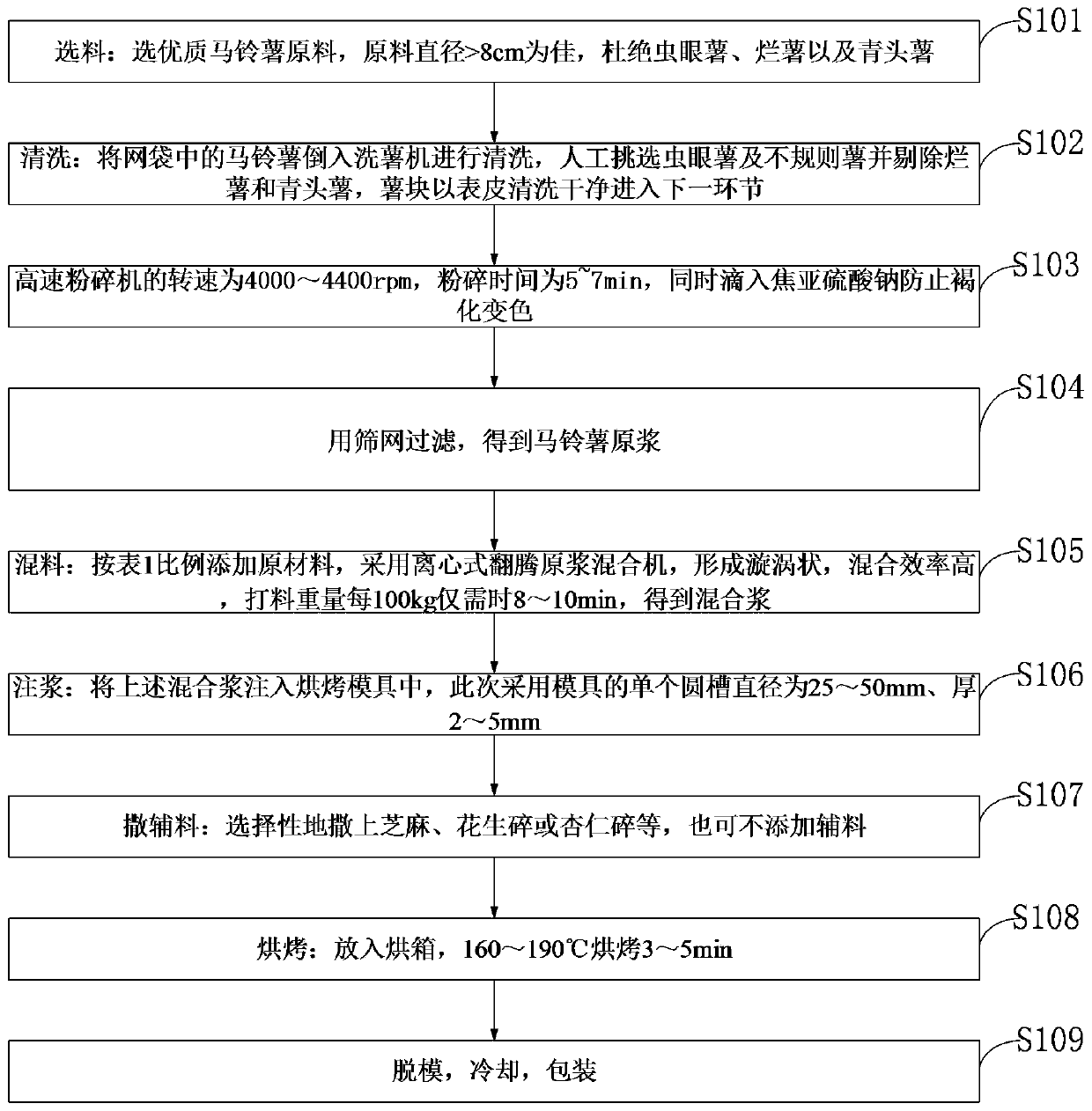

[0044] Such as figure 1 As shown, the method for preparing potato grain pellet pancakes based on fresh potato juice provided by the embodiments of the present invention includes:

[0045] S101, material selection: choose high-quality potato raw materials, preferably with a diameter > 8cm, and eliminate bug-eyed potatoes, rotten potatoes and green-headed potatoes.

[0046] S102, cleaning: pour the potatoes in the net bag into the potato washing machine for cleaning, manually select the bug-eyed potatoes and irregular potatoes and remove the rotten potatoes and green-headed potatoes, and clean the potato pieces with the skin to enter the next step.

[0047] S103, Juicing fresh whole potatoes: The speed of the high-speed pulverizer is 4000-4400rpm, and the pulverization time is 5-7min. 0.005% to 0.01% by weight of sodium metabisulfite is weighed to form a solution with a concentration of 1%).

[0048] S104, filtering: filtering through a sieve with a pore size of 1 mm, and prod...

Embodiment 1

[0063] Use the potato variety Atlantic (0.03% to 0.15% reducing sugar content) as raw material, remove bug-eyed potatoes, rotten potatoes and green-headed potatoes, and after full cleaning and manual selection, put them into a high-speed grinder for potato pulping, 4400rpm, 5min , while dropping 0.005% sodium metabisulfite solution to prevent browning and discoloration, and then filter through a 1mm sieve to obtain potato puree. Add raw materials according to the following parts by weight: 500 parts of potato puree, 50 parts of white granulated sugar, 20 parts of potato beef flavor seasoning, 20 parts of palm oil, 2 parts of salt, 100 parts of flour, 50 parts of egg liquid, 20 parts of highland barley flour, put Put into the puree mixer for thorough mixing. The mixed slurry is injected into the mould, and its single circular groove has a diameter of 30 mm and a thickness of 2 mm. Sprinkle sesame seeds evenly, bake at 180°C for 3 minutes, and then go through demoulding→cooling...

Embodiment 2

[0065] The potato variety Qingshu No. 9 (reducing sugar 0.253%) was selected as the raw material to remove worm-eyed potatoes, rotten potatoes and green-headed potatoes. After being fully cleaned and manually selected, put them into a high-speed grinder for potato pulping, 4400rpm, 5min, At the same time, 0.008% sodium pyrosulfite solution was added dropwise to prevent browning and discoloration, and then filtered through a 1 mm sieve to obtain potato puree. Add raw materials according to the following parts by weight: 600 parts of potato puree, 30 parts of white granulated sugar, 20 parts of Sichuan spicy seasoning, 20 parts of palm oil, 4 parts of salt, 200 parts of flour, 200 parts of egg liquid, miscellaneous grain powder (buckwheat, red bean , oats) 20 parts, put into the puree mixer and fully mix. The mixed slurry is injected into the mould, and its single circular groove has a diameter of 50 mm and a thickness of 3 mm. Sprinkle chopped peanuts evenly, bake at 190°C for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com