Method for preparing isohexadecane by using Pd-supported SAPO-31 molecular sieve nanocrystalline bifunctional catalyst

A SAPO-31, dual-function catalyst technology, applied in the field of isoparaffin production, can solve the problems of large grain size of micron molecular sieve, reduced isomerization reaction selectivity, increased catalyst cost, etc. The effect of improving yield, high reactivity and isomerization selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment 1: This embodiment is a method for preparing isohexadecane by using a Pd-loaded SAPO-31 molecular sieve nanocrystalline bifunctional catalyst, which is specifically completed according to the following steps:

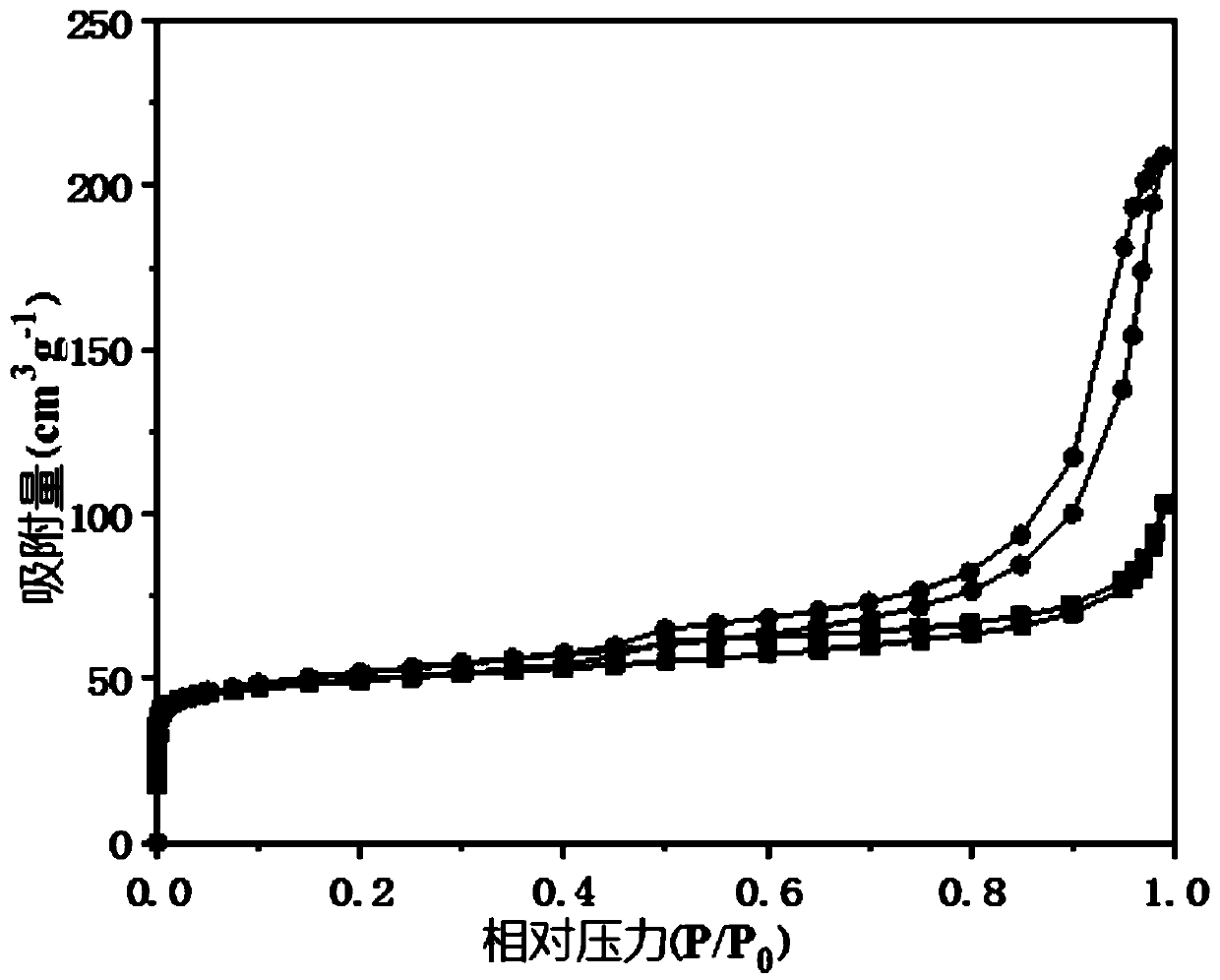

[0018] Using Pd-loaded SAPO-31 molecular sieve nanocrystals as a bifunctional catalyst, the hydroisomerization reaction of n-hexadecane is carried out on a fixed-bed reactor to produce isohexadecane; the Pd-loaded SAPO-31 molecular sieve The loading amount of Pd in the nanocrystalline bifunctional catalyst is 0.02wt% ~ 0.09wt%; the yield of isohexadecane reaches over 75%, and the proportion of multi-branched isomers in isohexadecane reaches over 50% .

specific Embodiment approach 2

[0019] Specific embodiment two: The difference between this embodiment and specific embodiment one is: the SAPO-31 molecular sieve nanocrystalline bifunctional catalyst loaded with Pd is prepared according to the following steps:

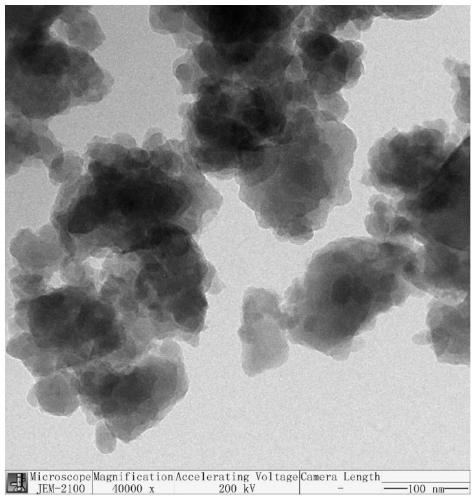

[0020] 1. Preparation of SAPO-31 molecular sieve nanocrystals: phosphoric acid as phosphorus source, pseudoboehmite as aluminum source, silica sol as silicon source, di-n-butylamine as template, 1-octyl-3-methyl chloride Imidazole is a crystal growth inhibitor. Add phosphorus source, aluminum source, silicon source, template agent and crystal growth inhibitor to deionized water in sequence, stir evenly to make initial gel, crystallize at 160-180°C for 12h-36h, Synthesize SAPO-31 molecular sieve nanocrystals, and the grain size of SAPO-31 molecular sieve nanocrystals is 30nm~50nm; the chlorinated 1-octyl-3-methylimidazole and pseudoboehmite in the initial gel Al 2 o 3 The molar ratio is 0.4:1;

[0021] 2. Loading Pd: SAPO-31 molecular sieve nanocr...

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the particle size of the bifunctional catalyst is 20-40 mesh. Others are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com