Antibacterial hydrogel with bactericidal, low bacterial adhesion and bacterial release, preparation method and application thereof

A technology of bacterial adhesion and hydrogel, applied in bandages, medical science, etc., can solve the problems of unsuitable for industrial mass production and application, poor biocompatibility of hydrogel, poor biocompatibility, etc., and achieve excellent biophase Compatibility, high biocompatibility, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Take 1.18g DVBAPS and 0.08g GMA and place them in a 25ml round bottom flask containing 5ml each of water and trifluoroethanol. After stirring for 30min under nitrogen, add 0.02g of azobisisobutyronitrile and continue the process under nitrogen. Stirring for 20min under the condition of 60°C, reacting for 6h, then lyophilizing to collect poly(DVBAPS-co-GMA) copolymer solid samples after dialysis for a period of time;

[0034] (2) Put 0.25g poly(DVBAPS-co-GMA) and 0.5g PEGDGE in a container, add 1ml brine, the concentration of brine is 0.5M, stir well at 60°C, add 0.5g lysine after dissolution and continue Stir to dissolve, transfer the solution to a spare mold, and place it in an air blast oven at 80° C. for 2 hours to obtain an antibacterial hydrogel with a thickness of 1 mm.

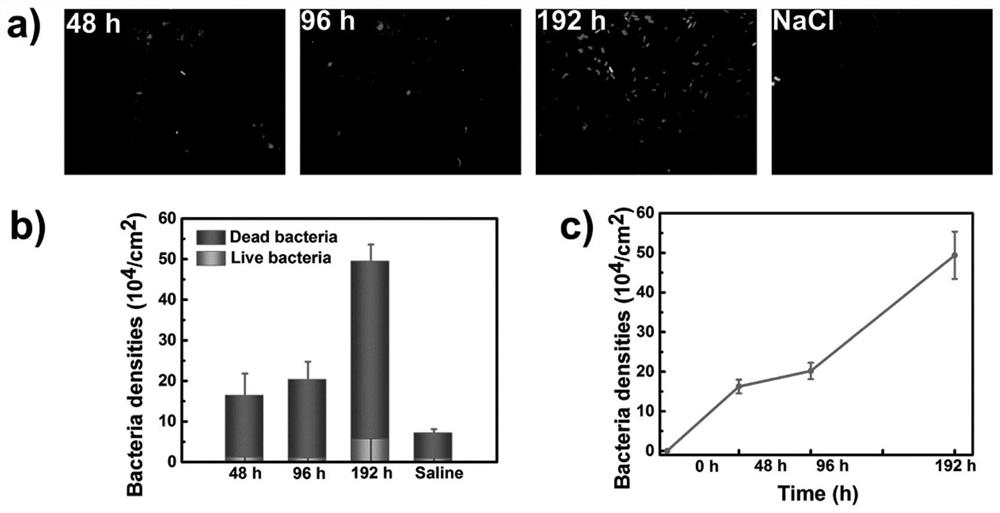

[0035] figure 2 It is the surface fluorescence micrograph of the antibacterial hydrogel obtained in Example 1 for sterilization, low bacterial adhesion, and bacterial release, and the relat...

Embodiment 2

[0038] (1) Take 1.18g DVBAPS and 0.08g GMA and place them in a 25ml round bottom flask containing 5ml each of water and trifluoroethanol. After stirring for 30min under nitrogen, add 0.02g of azobisisobutyronitrile and continue the process under nitrogen. Stirring for 20min under the condition of 60°C, reacting for 6h, then lyophilizing to collect poly(DVBAPS-co-GMA) copolymer solid samples after dialysis for a period of time;

[0039] (2) Take 1.25g HEAA and 0.08g GMA and place them in a 25ml round bottom flask containing 5ml each of water and dimethyl sulfoxide. After stirring for 30min under nitrogen gas, add 0.02g potassium persulfate and continue to nitrogen gas Stirring for 20 minutes under the condition of 60°C, reacting for 6 hours, then dialysis for a period of time and freeze-drying to collect poly(HEAA-co-GMA) copolymer solid samples;

[0040] (3) Put 0.25g poly(DVBAPS-co-GMA) and 0.5g poly(HEAA-co-GMA) into a container, add 1ml deionized water, stir well at 60°C, a...

Embodiment 3

[0042](1) Get 0.47g NIPAM and 0.08g GMA and place them in a 25ml round-bottomed flask containing 5ml of water and trifluoroethanol. After stirring for 30min under the condition of nitrogen, add 0.02g of azobisisobutyronitrile and continue the process under nitrogen. Stirring for 20 minutes under the condition of 60°C, reacting for 6 hours, then lyophilizing to collect poly(NIPAM-co-GMA) copolymer solid samples after dialysis for a period of time;

[0043] (2) Take 1.25g of HEAA and 0.08g of GMA and place them in a 25ml round bottom flask containing 5ml of water and 5ml of dimethyl sulfoxide, stir for 30min under nitrogen, add 0.02g of azobisisobutylcyanide Continue to stir for 20 min under nitrogen, react at 60°C for 6 h, then freeze-dry to collect poly(HEAA-co-GMA) copolymer solid samples after dialysis for a period of time;

[0044] (3) Take 0.25g poly(DVBAPS-co-GMA) and 0.5g poly(HEAA-co-GMA) in a container, add 0.5ml deionized water and 0.5ml dimethyl sulfoxide, fully Sti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com