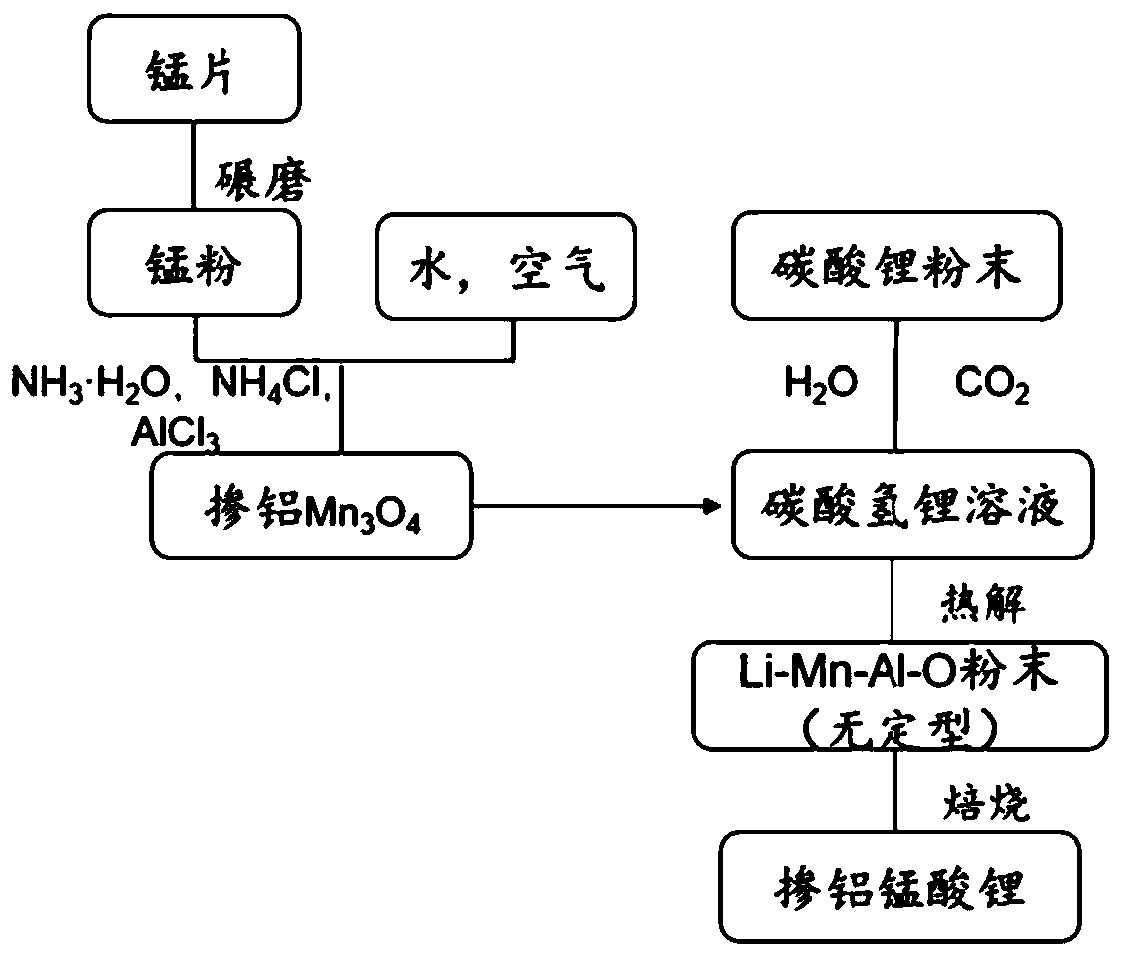

Preparation method of aluminum-doped lithium manganate

A technology of lithium aluminum manganate and manganese powder is applied in the field of preparation and modification of lithium manganate, which can solve the problems of low product capacity and poor cycle performance, and achieve the effects of wide product applicability, high capacity and lower production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

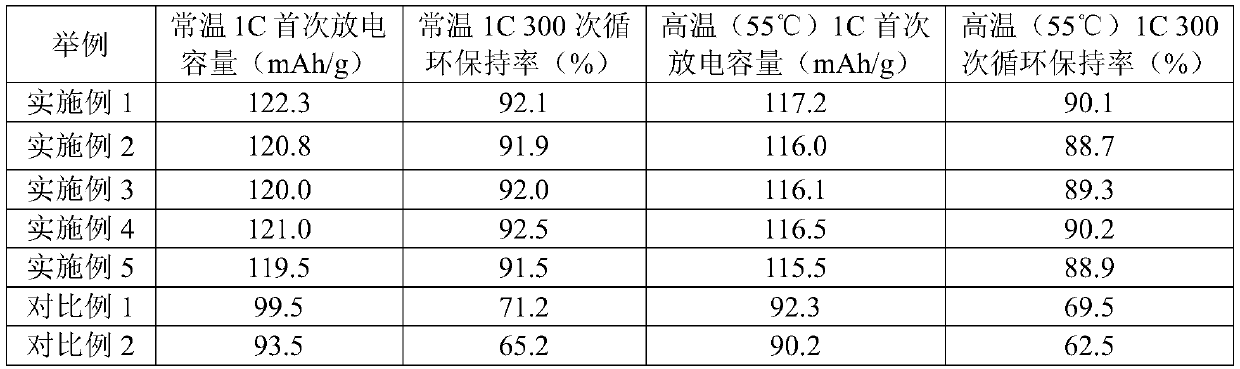

Examples

Embodiment 1

[0034] (1) Take 400g of manganese flakes, grind them with zirconia balls until the particle size is less than 200 mesh, add 2.60L of a mixed solution of water and 50g of ammonium chloride, control the temperature of the solution at 30°C, and use an air pump to inject air under stirring. reaction;

[0035] (2) when manganese powder oxidation reaction (whole oxidation reaction takes 18 hours) carries out 16h, add the mixed solution of ammoniacal liquor and ammonium chloride successively, aluminum chloride solution, the amount of aluminum chloride solution and ammoniacal liquor are respectively 0.073mol and 0.22mol, the mass fraction of aluminum chloride solution is 10%, the mass fraction of ammonia water is 30%, continue to react for 4h after the oxidation reaction is finished, after the reaction is finished, the filter cake obtained by filtering and washing is dried to obtain aluminum-doped trimanganese tetraoxide powder;

[0036] (3) Add 269g of industrial grade lithium carbon...

Embodiment 2

[0039] (1) Take 400g of manganese flakes, mill them with zirconia balls until the particle size is less than 400 mesh, add 1.33L of a mixed solution of water and 27g of ammonium chloride, control the temperature of the solution at 90°C, and use an air pump to feed air under stirring. reaction;

[0040] (2) when manganese powder oxidation reaction (whole oxidation reaction takes 10 hours) carries out 12h, add the mixed solution of ammoniacal liquor and ammonium chloride successively, aluminum chloride solution, the amount of aluminum chloride solution and ammoniacal liquor are respectively 0.29mol and 1.16mol, the mass fraction of aluminum chloride solution is 30%, the mass fraction of ammonia water is 30%, after the oxidation reaction is finished, continue to react for 2h, after the reaction is finished, the filter cake obtained by washing and filtering is dried to obtain aluminum-doped trimanganese tetraoxide powder;

[0041] (3) Add 135g of industrial grade lithium carbonate...

Embodiment 3

[0044] (1) Take 400g of manganese flakes, grind them with zirconia balls until the particle size is less than 300 mesh, add 2L of a mixed solution of water and 40g of ammonium chloride, control the temperature of the solution at 60°C, and use an air pump to feed air under stirring for reaction ;

[0045](2) when manganese powder oxidation reaction (whole oxidation reaction takes 16 hours) carries out 14h, add the mixed solution of ammoniacal liquor and ammonium chloride successively, aluminum chloride solution, the amount of aluminum chloride solution and ammoniacal liquor are respectively 0.22mol and 0.77mol, the mass fraction of the aluminum chloride solution is 26%, the mass fraction of ammonia water is 30%, the reaction is continued for 4h after the oxidation reaction is finished, and the filter cake obtained by washing and filtering after the reaction is finished is dried to obtain aluminum-doped trimanganese tetraoxide powder;

[0046] (3) Add 202g of industrial grade li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com