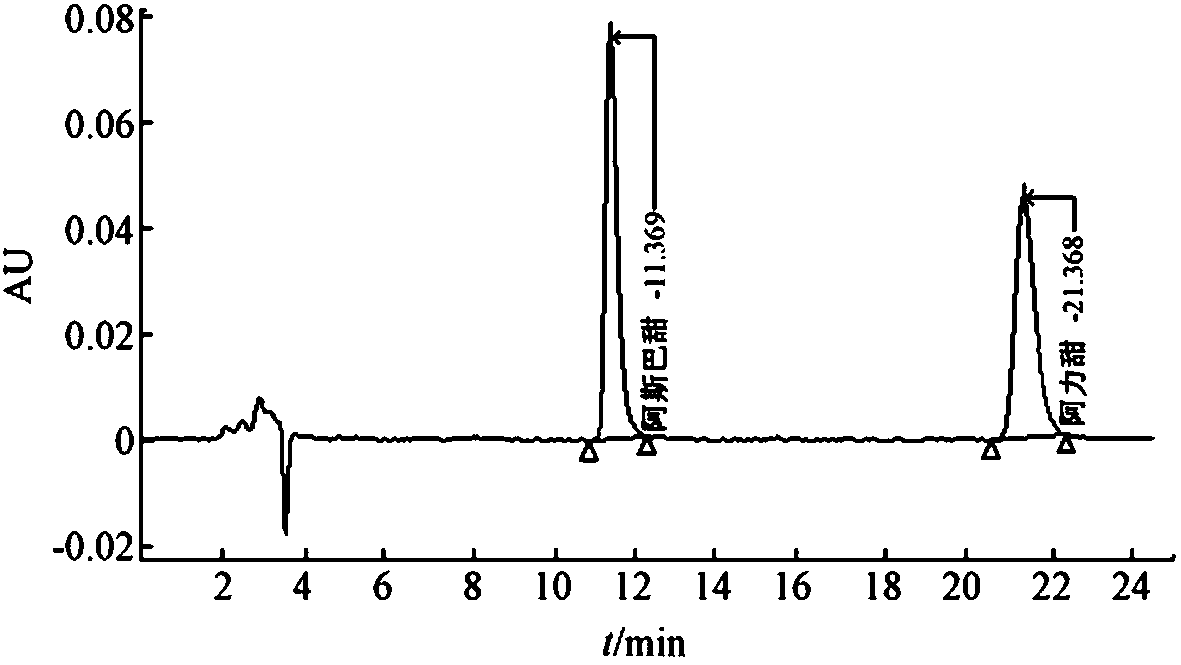

Method for measuring aspartame and alitame in food by reversed phase liquid chromatography mixed-standard sample-adding incremental process

A technology of reversed-phase liquid chromatography and aspartame, which is applied in the field of food testing, can solve the problems of different degrees of interference and side reactions in the measurement results, simultaneous and simultaneous measurement, and different background backgrounds, etc., achieving low cost, High accuracy and reduced interference effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

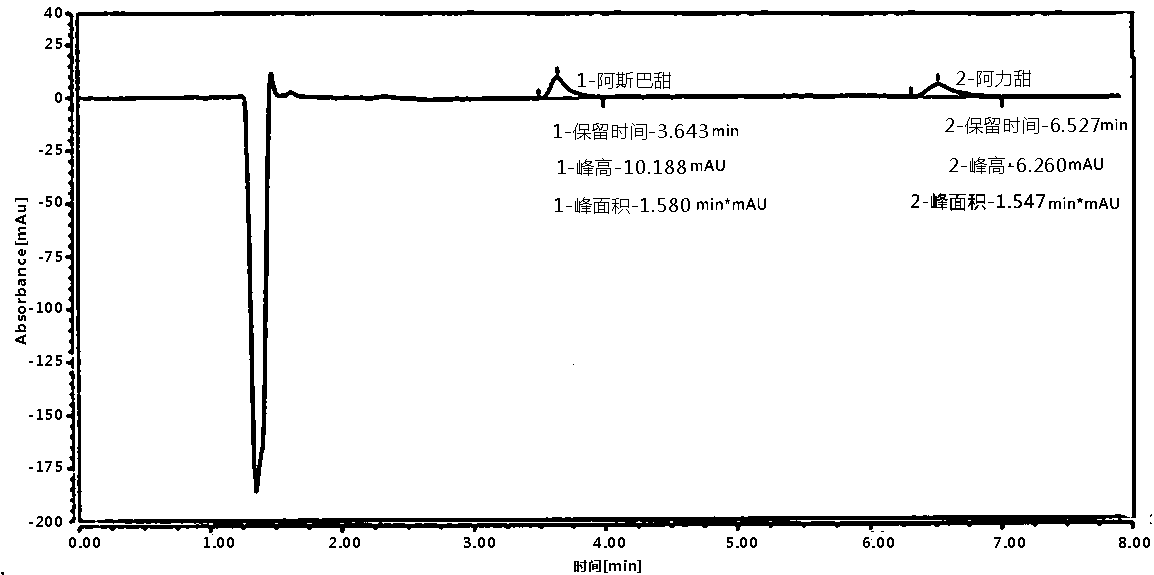

[0080] Weigh about 5.000g (accurate to 0.001g) Coca-Cola carbonated beverage sample in a 50mL beaker, remove carbon dioxide on an ultrasonic oscillator, transfer all of it to a 25mL volumetric flask with water to make up the volume, mix well, and the measured components reach the concentration Balance, 4000r / min centrifuge for 5min, the concentration of aspartame and alitame in the supernatant and the lower layer are the same, centrifugation is to precipitate the particulate matter that may exist in the sample, take the supernatant and filter it with 0.45μm water system After membrane filtration, the liquid to be tested was obtained for chromatographic analysis.

[0081] Take two identical centrifuge tubes A and B, add 50 μL of 10 μg / mL aspartame and alitame mixed standard solution respectively, then add 100 μL of Coca-Cola test solution to centrifuge tube A, and dilute to 1 mL; Add 200 μL of Coca-Cola to-be-tested solution to centrifuge tube B, and dilute to 1 mL. Finally, t...

Embodiment 2

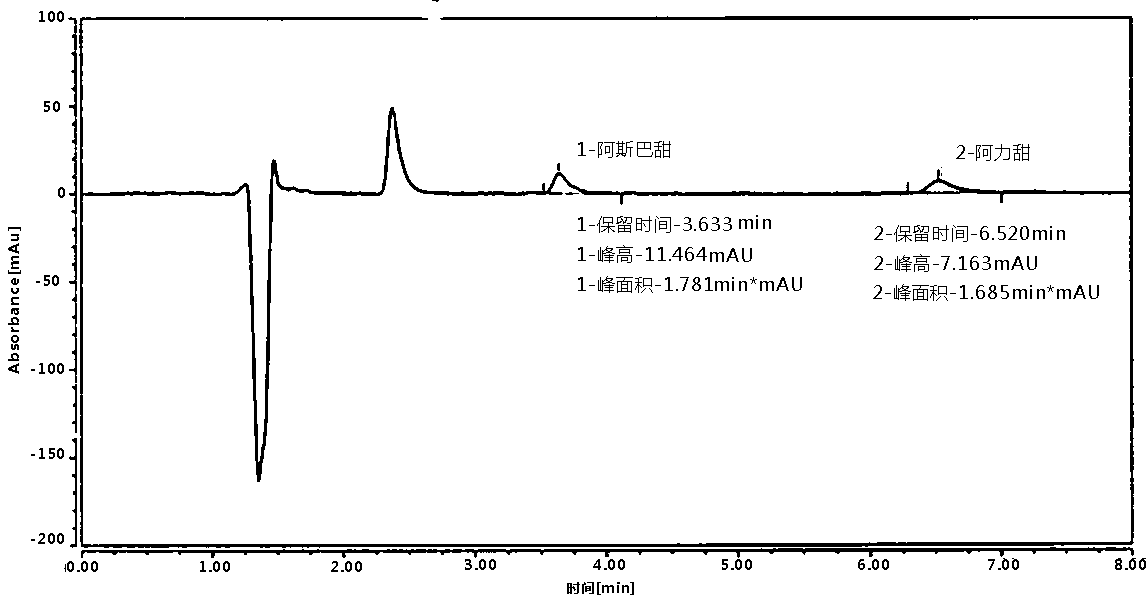

[0110] Weigh about 1.000g (accurate to 0.001g) chrysanthemum crystal sample in a 50mL beaker, add 10mL water, extract by ultrasonic vibration for 20min, transfer the extract into a 25mL volumetric flask, add 10mL water to the residue and ultrasonically extract for 10min, Transfer the extract into the same 25mL volumetric flask, dilute to volume with water, mix well, the measured components reach concentration balance, centrifuge at 4000r / min for 5min, aspartame and alitame in the supernatant and lower layer The concentrations are the same, centrifugation is to precipitate the particulate matter that may exist in the sample, take the supernatant and filter it with a 0.45 μm water filter membrane to obtain the test solution for chromatographic analysis.

[0111] Take two identical centrifuge tubes A and B, add 50 μL of 10 μg / mL aspartame and alitame mixed standard solution respectively, then add 100 μL of chrysanthemum crystal test solution to centrifuge tube A, and dilute to 1 m...

Embodiment 3

[0127] Weigh 5.000g (accurate to 0.001g) of yogurt sample into a 50mL centrifuge tube, add 10mL of ethanol to precipitate the protein in the yogurt sample, close the lid tightly, gently invert the centrifuge tube 5 times up and down (do not shake), and place After the centrifuge tube was mixed and vortexed for 10s, let it stand for 1min, centrifuged with a 4000r / min centrifuge for 5min, took the supernatant and filtered it into a 25mL volumetric flask, washed the filter residue with 8mL ethanol-water (2+1), and centrifuged the supernatant The solution was transferred into the same volumetric flask. Centrifugation is convenient for filtering a small amount of protein precipitation and other filter residues. After the components to be tested in the sample to be tested are completely extracted into the supernatant, use ethanol-water (2+1) to make up to 25mL, and use 0.45 After filtering with a μm organic filter membrane, the test solution was obtained for liquid chromatography ana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com