Photochromic material and application thereof

A technology of photochromic materials and dosage ratio, applied in the field of materials, can solve the problems of low discoloration efficiency, waste water pollution, hinder the development of tungsten oxide/molybdenum photochromic materials, etc., and achieve the effect of high discoloration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

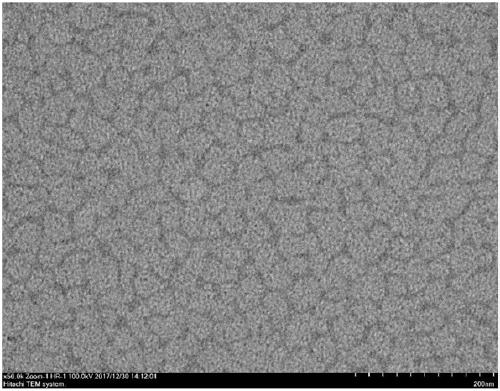

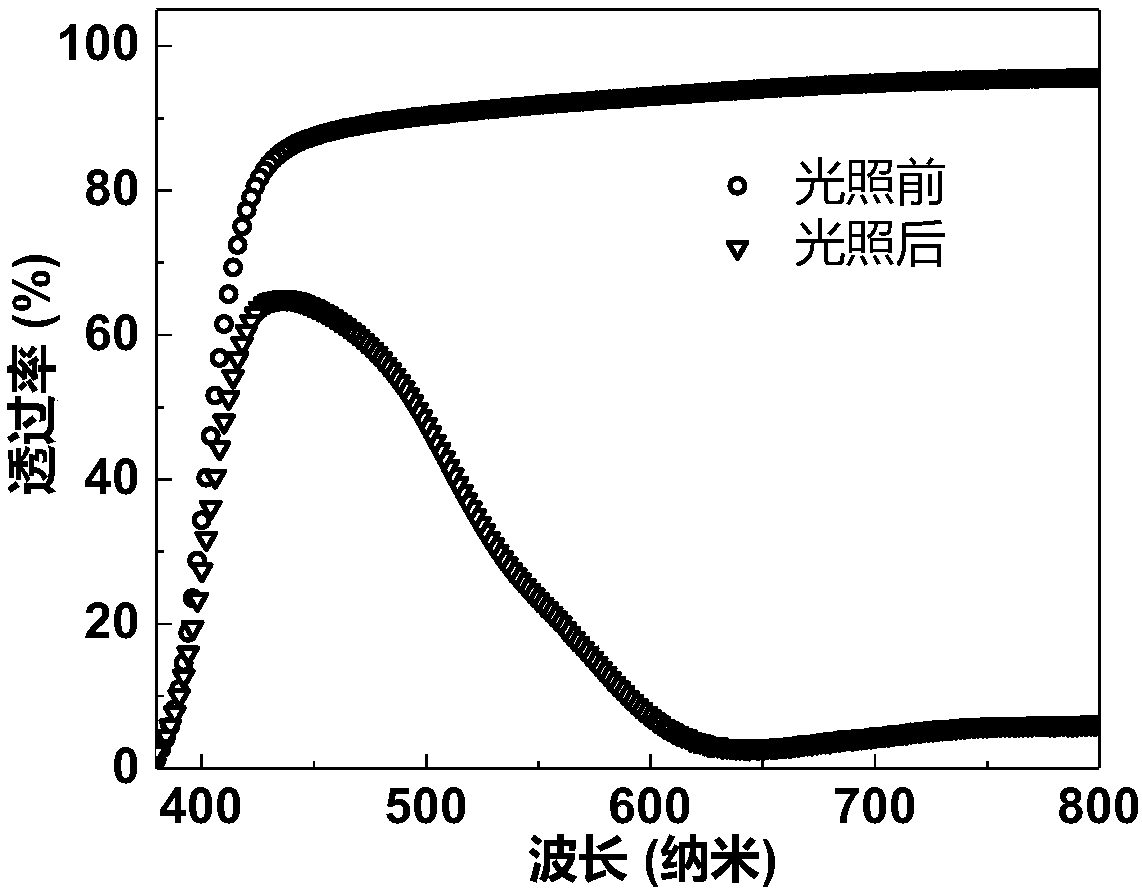

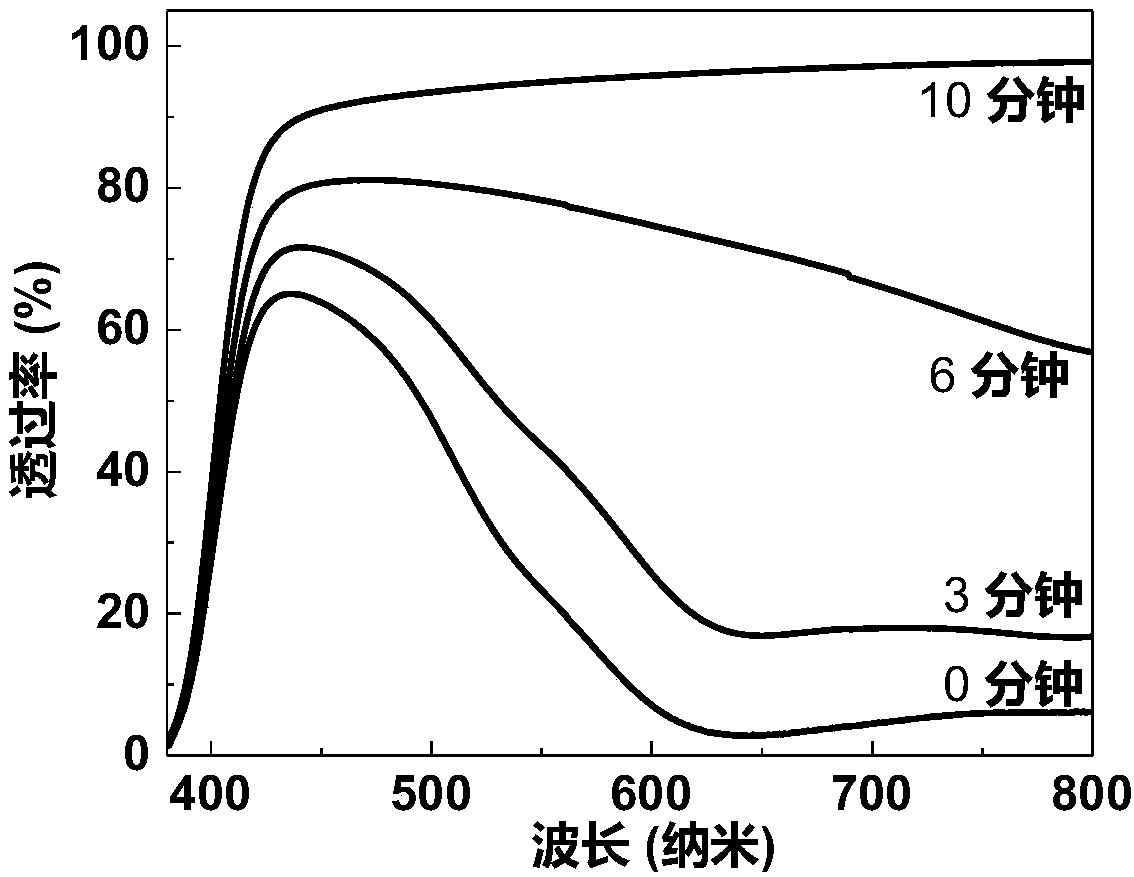

Image

Examples

Embodiment 1

[0043] Weigh 0.5g of sodium tungstate and add it to a 250mL beaker containing 150mL of deionized water, and stir for 15 minutes with a magnetic stirrer; weigh 0.6g of disodium edetate and add it to the above mixture, and use an electric heating mantle Heating to 50°C and continuing to stir for 25 minutes to obtain a mixed solution;

[0044] Measure 4mL hydrochloric acid with a 5mL pipette purchased from the market along the beaker wall and slowly add it into a 50mL beaker filled with 16mL deionized water, the pH of the acid solution is 1; weigh 0.15g polyvinylpyrrolidone and add The above acid solution, and continuously stirred with a glass rod until well mixed;

[0045] Transfer the above acid solution to a dropping funnel with a volume of 50mL, fix the dropping funnel above the above 250mL beaker with an iron stand, control the dropping speed to 2 drops / second, and add the acid solution dropwise to the above mixed solution In the process, until the pH value of the above sol...

Embodiment 2

[0051] Weigh 0.2g of sodium tungstate and add it to a 100mL beaker containing 80mL of deionized water, and stir for 15 minutes with a magnetic stirrer; weigh 0.6g of lauroyl glutamic acid and add it to the above mixture, and heat it to Continue stirring at 80°C for 10 minutes to obtain a mixed solution;

[0052] Measure 1.5mL sulfuric acid with a 5mL pipette purchased from the market along the beaker wall and slowly add it into a 25mL beaker containing 8.5mL deionized water, the pH of the acid solution is 1; weigh 0.1g octave Alkyl sodium sulfate is added to the above acid solution, and continuously stirred with a glass rod until it is evenly mixed;

[0053] Transfer the above acid solution to a dropping funnel with a volume of 25mL, fix the dropping funnel above the above 100mL beaker with an iron stand, control the dropping speed to 1 drop / second, and add the acid solution dropwise to the above mixed solution In the process, until the pH value of the above solution is 3, th...

Embodiment 3

[0056] Weigh 0.35g of sodium molybdate into a 250mL beaker containing 100mL of ethanol, and stir for 15 minutes with a magnetic stirrer; weigh 0.5g of cetyltrimethylammonium bromide into the above mixture, and heat it with electricity Heat the jacket to 40°C and continue to stir for 10 minutes to obtain a mixed solution;

[0057] Measure 0.5mL of acetic acid with a commercially available pipette gun with a range of 1mL and slowly add it along the beaker wall into a 25mL beaker containing 9.5mL of deionized water, the pH of the acid solution is 2.5; weigh 0.2g of fatty alcohol Sodium polyoxyethylene ether sulfate is added to the above acid solution, and continuously stirred with a glass rod until it is evenly mixed;

[0058] Transfer the above acid solution to a dropping funnel with a volume of 25mL, fix the dropping funnel above the above 250mL beaker with an iron stand, control the dropping speed to 3 drops / 10 seconds, and add the acid solution dropwise to the above mixing I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com