Acidic high temperature resistant recombinant cellulase and its application

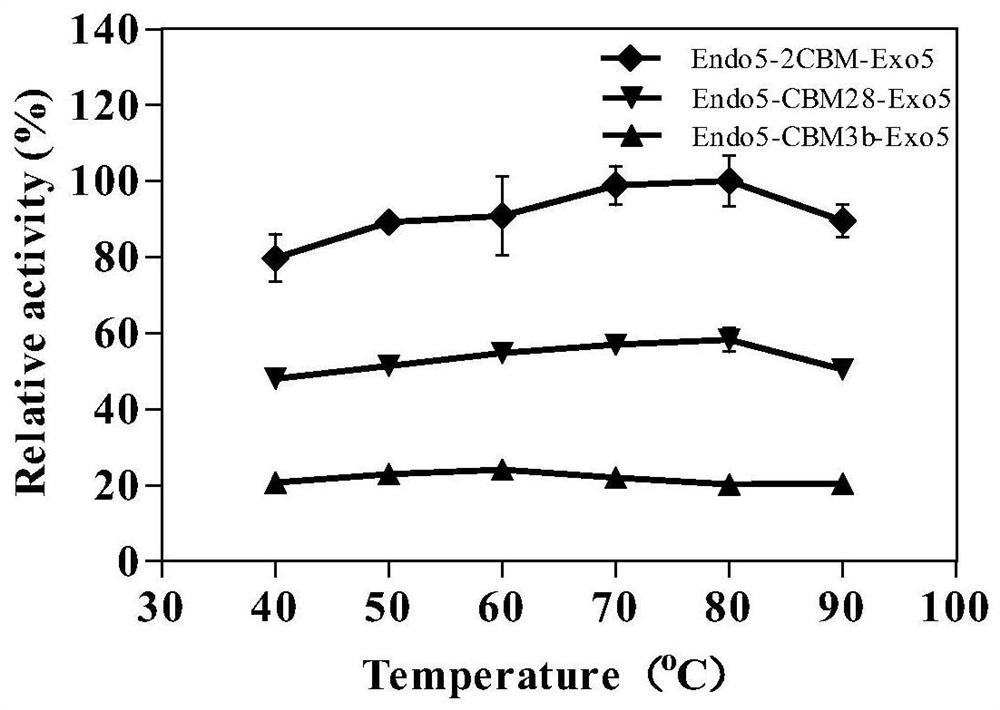

A technology of cellulase and high temperature resistance, which is applied in the field of genetic engineering technology and biomass refining, can solve the problem of Avicel's lack of activity, and achieve the effect of good activity and excellent enzymatic hydrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Gene preparation of endoglucanase (Endo5), carbohydrate binding domain (CBM) and exoglucanase (Exo5).

[0042] The original endo5-cbm28, endo5, cbm3b-exo5 and exo5 genes in the prior art can be prepared by artificial synthesis, or the total DNA of Caldicellulosiruptor saccharolyticus (purchased from the American Culture Collection) can be obtained by PCR as a template.

[0043] The new endo5-cbm28, endo5, cbm3b-exo5 and exo5 genes in this example are based on the binding characteristics of enzymes Endo5-CBM28, Endo5, CBM3b-Exo5 and Exo5 to substrates, and new sequences were designed through sequence alignment, prediction and design. , and sent the new sequence to Shanghai Sangon for full gene synthesis. The designed new gene has better activity for substrates such as CMC-Na, filter paper, Avicel, and natural lignocellulose, and the enzymatic hydrolysis effect is better.

[0044] Using the new sequences synthesized from the whole gene as templates, the following new pri...

Embodiment 2

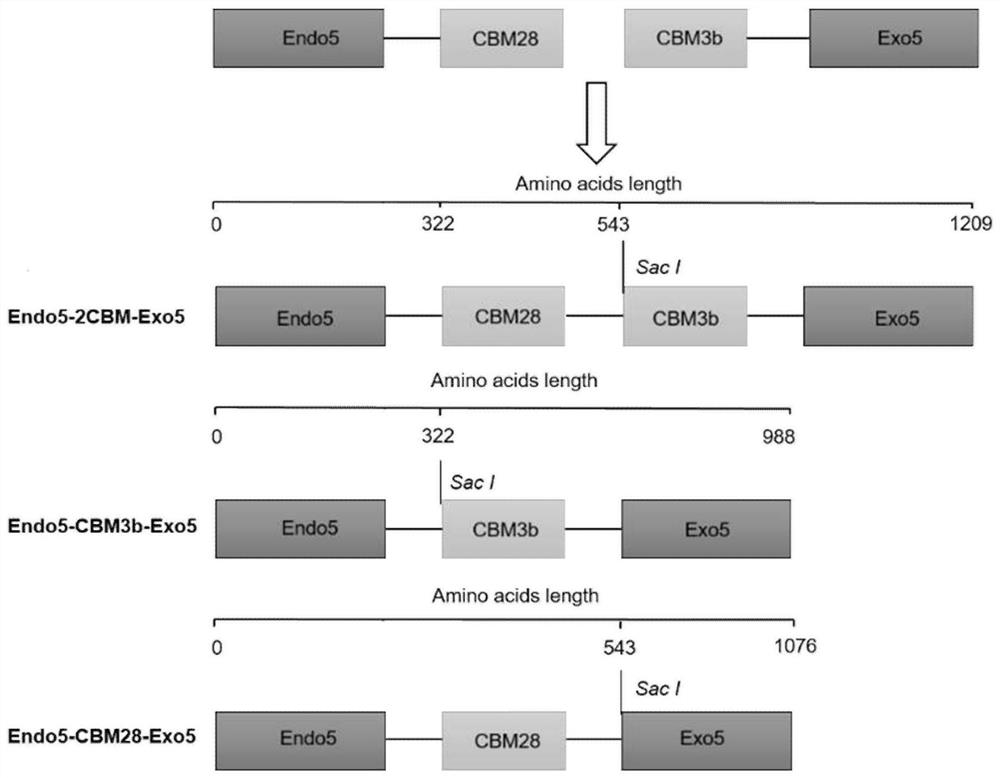

[0057] Construction and verification of recombinant cloning and expression vectors pET28a-endo5-2cbm-exo5, pET28a-endo5-cbm3b-exo5 and pET28a-endo5-cbm28-exo5

[0058] The purified PCR products endo5-cbm28, endo5 (prepared in Example 1) and pET28a (Novagen) were double digested with NcoI and SacI, respectively, and the digested PCR fragments and vector large fragments were recovered by agarose gel electrophoresis. The target fragment and carrier recovered by gel tapping were concentrated and resuspended in 8 μL of sterile water. Add 1 μL of 10× LigaseBuffer and 1 μL of Ligase, and ligate overnight at 16°C. The ligation product was transformed into Escherichia coli (E.coliDH5a), then spread on LB solid medium containing 50 μg / mL kanamycin (Kan), and cultured at 37°C for 13-15 h.

[0059] Pick multiple single colonies from the transformation plate, and use Shanghai Sangon plasmid extraction kit to extract plasmids. The extracted plasmids were verified by double-enzyme digestio...

Embodiment 3

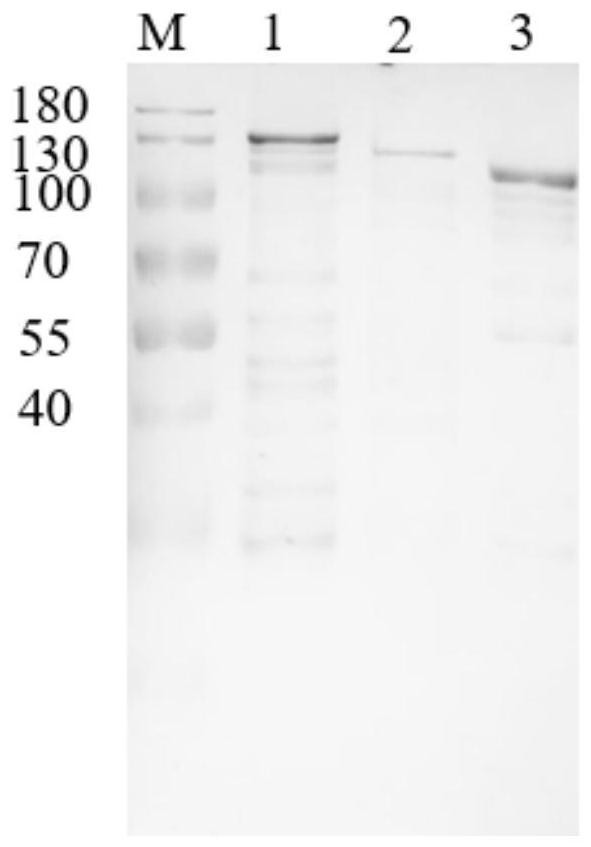

[0062] Expression and purification of recombinant cellulases Endo5-2CBM-Exo5, Endo5-CBM3b-Exo5 and Endo5-CBM28-Exo5.

[0063] The recombinant clones, expression vectors pET28a-endo5-2cbm-exo5, pET28a-endo5-cbm3b-exo5 and pET28a-endo5-cbm28-exo5 (prepared in Example 2) were chemically transformed into the expression host E. coliBL21 (DE3) (Novagen), Recombinant bacteria containing recombinant plasmids were obtained. The positive recombinants were inoculated into 5 mL of Luria-Bertanibroth (LB) liquid medium containing 50 μg / mL Kan, and cultured overnight at 37° C. and 200 rpm. Transfer 4 mL of bacterial liquid to 500 mL of LB liquid medium containing 50 μg / mL Kan, and cultivate the bacterial concentration (OD) under the conditions of 37 ° C and 200 rpm. 600 ) to 0.6 to 0.8. IPTG with a final concentration of 0.5mM was added, and expression was induced at 25°C and 200rpm for 12-14h. The culture solution was centrifuged in a high-speed refrigerated centrifuge at 4° C., 10,000 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com