Method and system for preparing solar cell used for PERC imbrication component

A technology for solar cells and modules, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of increased production costs, consumption of large energy, consumption of precious metal paste, etc., to achieve the effect of satisfying normal packaging and reducing power loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] Hereinafter, the method for preparing a solar cell sheet for a PERC shingled assembly, the method for preparing a PERC shingled assembly, the solar cell sheet for a PERC shingled assembly, the PERC shingled assembly, And a system for preparing solar cells for use in PERC shingled modules. Provided below are only preferred embodiments according to the present invention, and those skilled in the art can think of other ways to realize the present invention on the basis of the preferred embodiments, and the other ways also fall within the scope of the present invention .

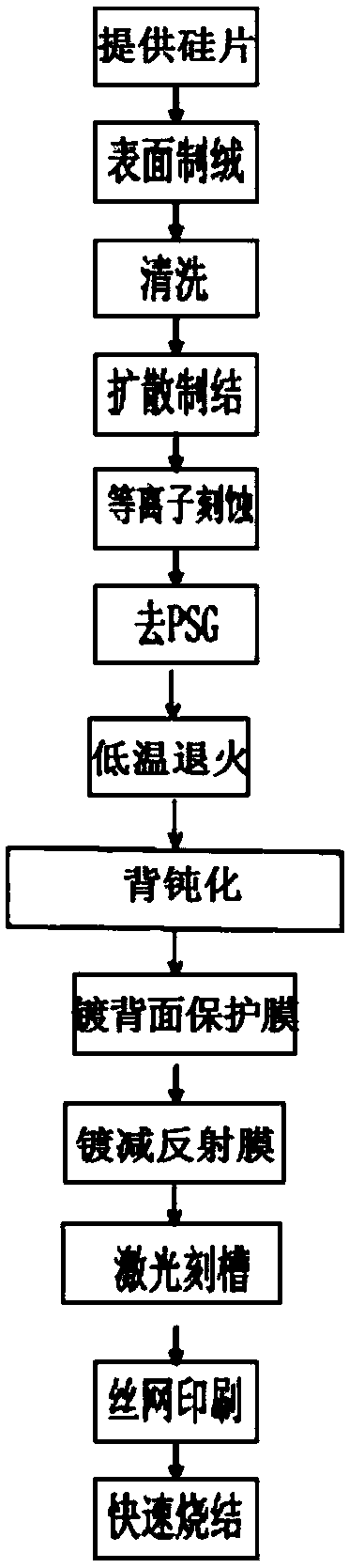

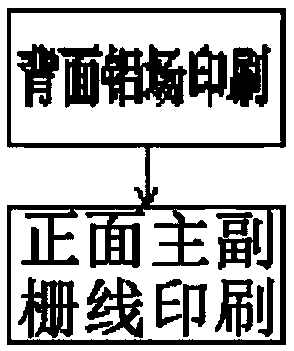

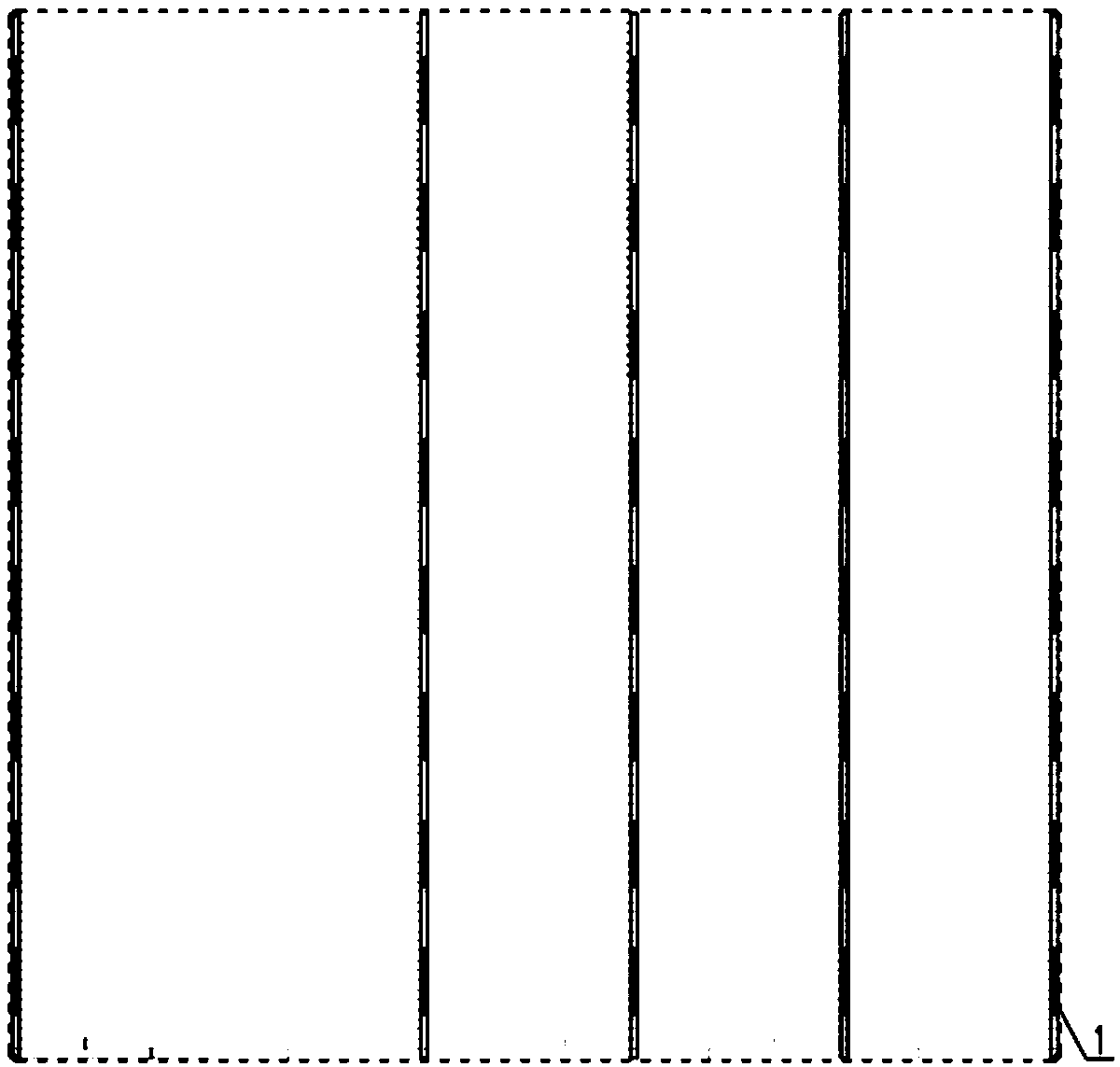

[0055] see Figure 1A , which shows an exemplary flowchart of a method for preparing a solar cell sheet for a PERC shingled module according to the present invention, which will be described in detail below.

[0056] Firstly, the method for preparing solar cells for PERC shingled modules according to the present invention includes the step of providing silicon wafers to provide silicon wafers. According...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com