Liquid dressing and preparing method thereof

A technology of liquid dressing and formula, which is applied in medical formula, medical science, drug delivery, etc. It can solve the problems of low water vapor transmission rate and achieve low water diffusion properties, rapid and effective hemostasis, and fast film formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

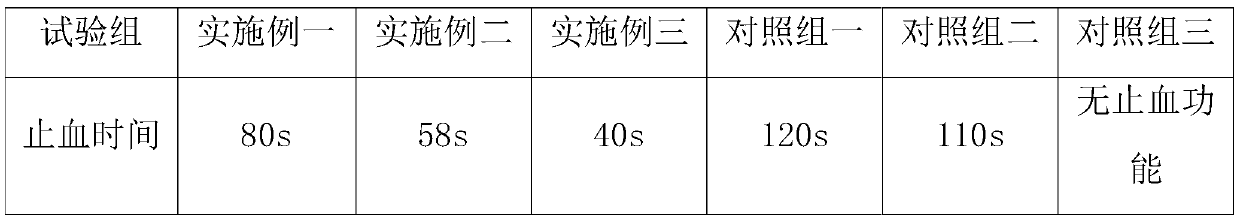

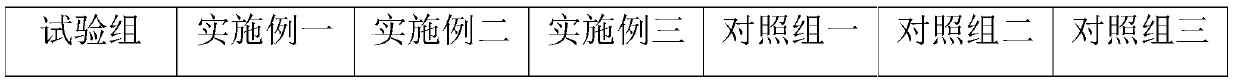

Examples

Embodiment 1

[0029] (1) In a dry environment at room temperature, weigh 30g of α-butyl cyanoacrylate, 40g of silicon dioxide, 18g of ether, 1.5g of anhydrous citric acid and 0.5g of salicylic acid, and mix them evenly.

[0030] (2) In a dry environment at room temperature, the cans of the liquid dressing prepared in step (1) are filled into aluminum aerosol cans, and high-pressure nitrogen is used as a propellant.

[0031] The closed environment refers to a closed stirred tank at 20-25°C under the protection of dry gas, wherein the controlled drying environment is a temperature of 20-25°C and a relative humidity of 5-15%.

Embodiment 2

[0033] (1) In a dry environment at room temperature, weigh 30g α-butyl cyanoacrylate, 40g α-octyl cyanoacrylate, 10g silicon dioxide, 17.9g ether, 2g anhydrous citric acid and 0.1g salicylic acid, mix uniform.

[0034] (2) In a dry environment at room temperature, the cans of the liquid dressing prepared in step (1) are filled into aluminum aerosol cans, and high-pressure nitrogen is used as a propellant.

Embodiment 3

[0036] (1) In a dry environment at room temperature, weigh 40g of α-octyl cyanoacrylate, 19.5g of silicon dioxide, 40g of ether, 0.1g of anhydrous citric acid and 0.4g of salicylic acid, and mix them evenly.

[0037](2) In a dry environment at room temperature, the cans of the liquid dressing prepared in step (1) are filled into aluminum aerosol cans, and high-pressure nitrogen is used as a propellant.

[0038] Control group 1: Choose similar products that are already on the market. The product used in this control group is Minrong Machinery Equipment 20170034. The main components are acrylic resin, acetyl tributyl citrate, and ethanol.

[0039] Control group 2: Choose similar products already on the market. The product selected in this control group is Sujizhun 20170080. The main components are propylene hydrochloride copolymer, glycerin, Tween 80, triethyl citrate, ethanol, and purified water. composition.

[0040] Control group 3: In a dry environment at room temperature, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hygroscopicity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com