Composite water treatment agent for heavy metal wastewater treatment and preparation method of composite water treatment agent

A technology for wastewater treatment and water treatment, applied in water/sewage treatment, adsorbed water/sewage treatment, water/sludge/sewage treatment, etc. and other problems, to achieve the effect of enhancing the ability to adsorb heavy metals, promoting compatibility, and improving the performance of adsorbing heavy metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

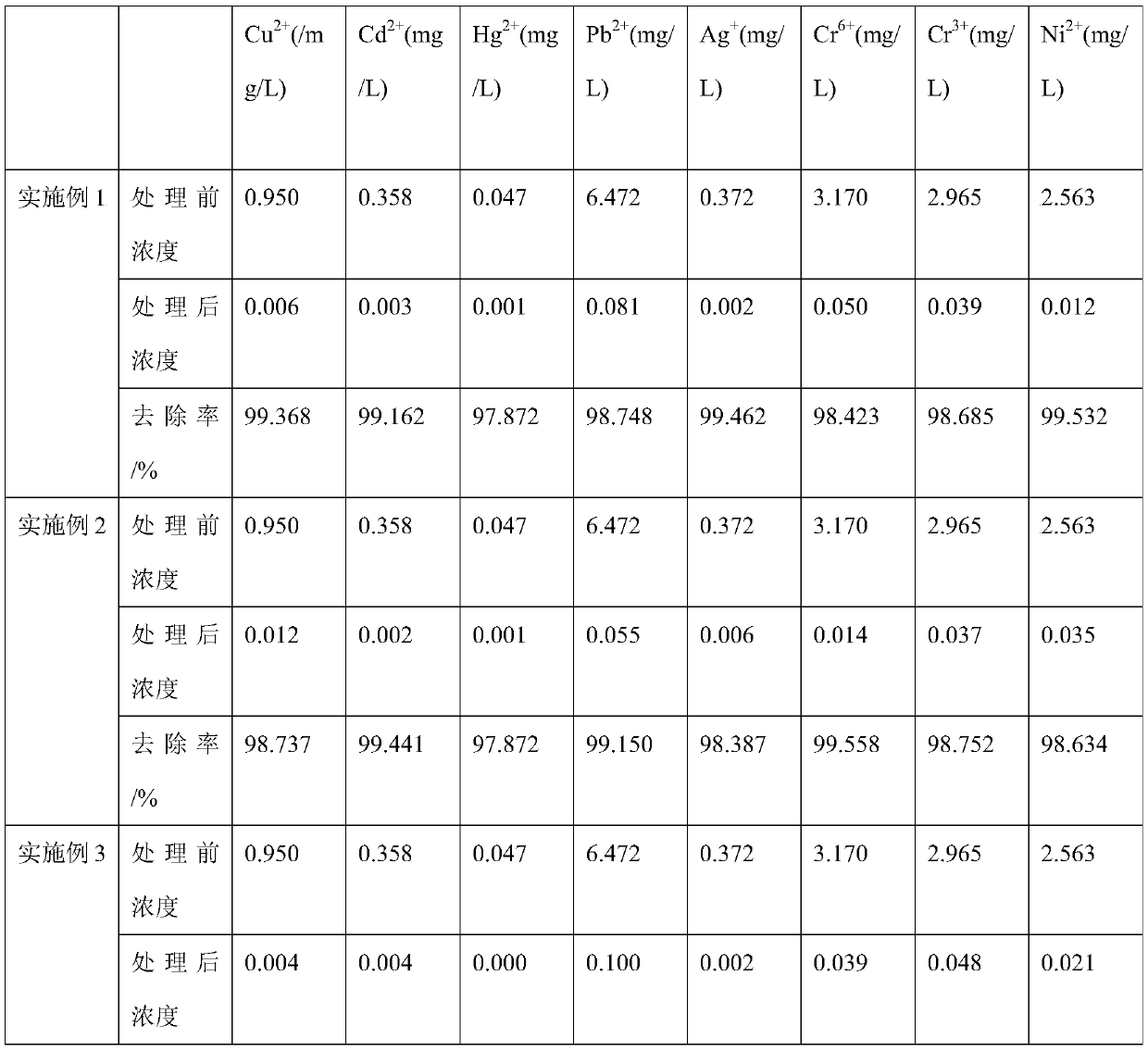

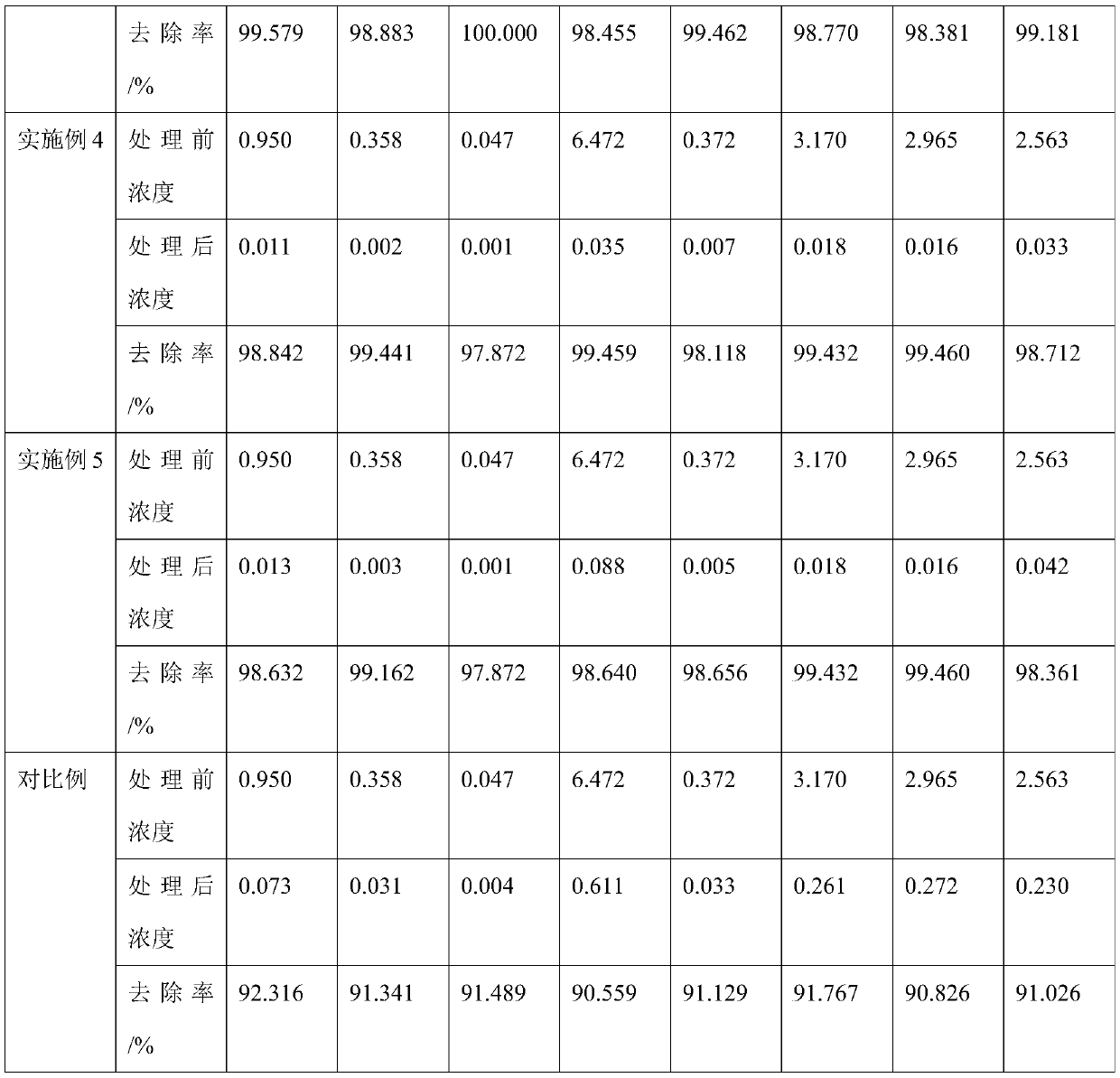

Embodiment 1

[0025] A composite water treatment agent for the treatment of heavy metal wastewater, the raw materials of the composite water treatment agent and their weight / number ratios are: 25 parts of polyglutamic acid, 22 parts of starch, 12 parts of FeCl 3 ·6H 2 O, 12 parts of FeSO 4 ·7H 2 O, 20 parts of sodium silicate, 18 parts of humic acid, 12 parts of diatomaceous earth, 8 parts of magnesium stearate, 10 parts of sugarcane waste residue, 30 parts of polyethylene glycol 200, and 8 parts of tributyl phosphate.

[0026] A method for preparing a composite water treatment agent for heavy metal wastewater treatment, comprising the following steps:

[0027] Step 1) modified Fe 3 o 4 Particle preparation: Take 12 parts of FeCl 3 ·6H 2 O, 12 parts of FeSO 4 ·7H 2 O was dissolved in 25 parts of distilled water, stirred for 6 min at a stirring rate of 30 r / min, then 30 parts of polyethylene glycol 200 was added, and the prepared 2 mol L was rapidly added dropwise under nitrogen prot...

Embodiment 2

[0031] A composite water treatment agent for the treatment of heavy metal wastewater, the raw materials of the composite water treatment agent and their weight / number ratios are: 30 parts of polyglutamic acid, 30 parts of starch, 18 parts of FeCl 3 ·6H 2 O, 18 parts of FeSO 4 ·7H 2 O, 26 parts of sodium silicate, 20 parts of humic acid, 16 parts of diatomaceous earth, 10 parts of magnesium stearate, 16 parts of sugarcane waste residue, 35 parts of polyethylene glycol 400, and 12 parts of tributyl phosphate.

[0032] A method for preparing a composite water treatment agent for heavy metal wastewater treatment, comprising the following steps:

[0033] Step 1) modified Fe 3 o 4 Particle preparation: Take 18 parts of FeCl 3 ·6H 2 O, 18 parts of FeSO 4 ·7H 2 O was dissolved in 40 parts of distilled water, stirred for 8 minutes at a stirring rate of 40 r / min, then 35 parts of polyethylene glycol 400 was added, and the prepared 2mol L was rapidly added dropwise under nitrogen...

Embodiment 3

[0037] A composite water treatment agent for the treatment of heavy metal wastewater, the raw materials of the composite water treatment agent and their weight / number ratios are: 28 parts of polyglutamic acid, 28 parts of starch, 17 parts of FeCl 3 ·6H 2 O, 15 parts of FeSO 4 ·7H 2 O, 22 parts of sodium silicate, 19 parts of humic acid, 14 parts of diatomaceous earth, 9.5 parts of magnesium stearate, 12 parts of sugarcane waste residue, 32 parts of polyethylene glycol 1000, and 10 parts of tributyl phosphate.

[0038] A method for preparing a composite water treatment agent for heavy metal wastewater treatment, comprising the following steps:

[0039] Step 1) modified Fe 3 o 4 Particle preparation: Take 17 parts of FeCl 3 ·6H 2 O, 15 parts of FeSO 4 ·7H 2 O was dissolved in 30 parts of distilled water, stirred for 7 minutes at a stirring rate of 32 r / min, then 32 parts of polyethylene glycol 1000 was added, and the prepared 2mol L was rapidly added dropwise under nitro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com