Fe2O3 porous nanowire electrode material, and preparation method and application thereof

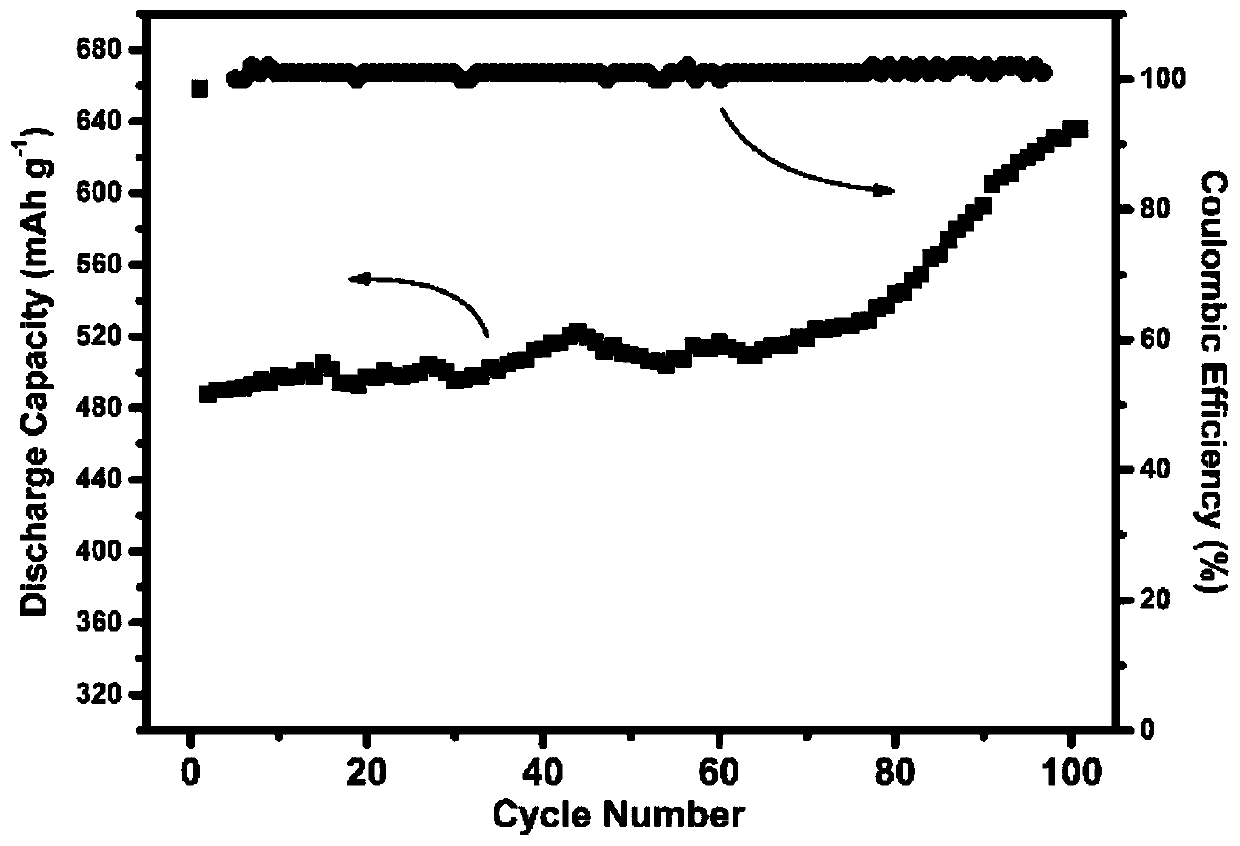

A technology of porous nanowires and electrode materials, which is applied in the field of electrochemical materials, can solve the problems of limiting the commercial application of iron-based oxides, poor electrical conductivity of iron-based oxides, and the decline in the performance of lithium-ion batteries, so as to benefit the electrolyte. Effects of penetration, shortening ion transmission distance, and suppressing volume expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

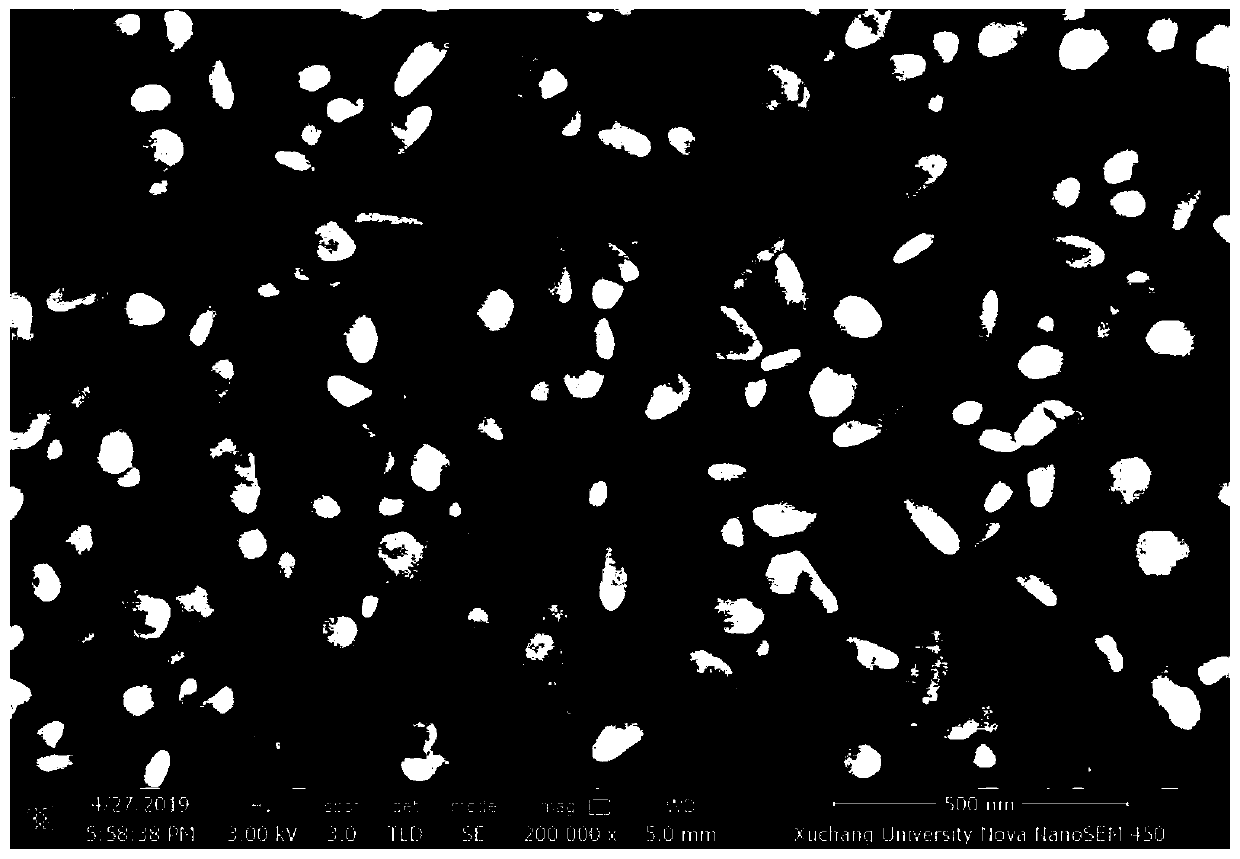

[0031] A kind of stainless steel base Fe 2 o 3 A method for preparing a porous nanowire electrode material, comprising the steps of:

[0032] (1) Put the stainless steel sheet current collector at a concentration of 2mol L -1 Soak in the HCl solution for 15 minutes, then wash with deionized water to remove organic and inorganic impurities, and dry for later use;

[0033] (2) ZnO seed crystal preparation:

[0034] Weigh 1mmol of zinc acetate and 1mmol of triethanolamine, add 50mL of ethanol to prepare a mixed solution A, immerse the cleaned stainless steel sheet current collector in the mixed solution A and slowly take it out, repeat 5 times, dry it, and put it in a tube furnace. Calcined at 350°C for 1 hour to obtain ZnO seed crystals;

[0035] (3) Preparation of ZnO nanoarrays:

[0036] Weigh 1mmol of zinc chloride, 1mmol of hexamethylenetetramine, and 1g of nonylphenol polyoxyethylene ether, add 40mL of deionized water to prepare a mixed solution B, pour the mixed solut...

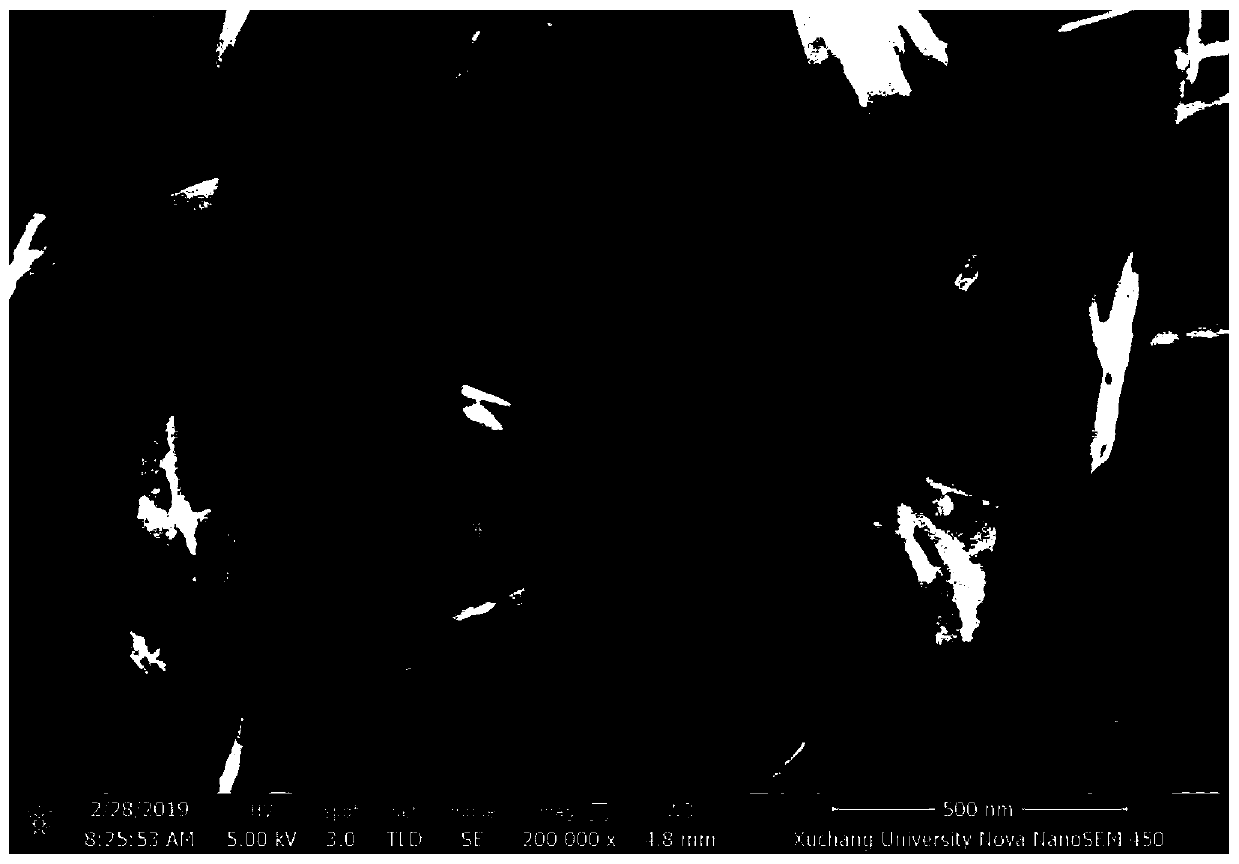

Embodiment 2

[0040] A metal nickel mesh based Fe 2 o 3 A method for preparing a porous nanowire electrode material, comprising the steps of:

[0041] (1) Put a nickel foam current collector with a thickness of 1mm in a concentration of 2mol L -1 Soak in the HCl solution for 15 minutes, remove organic and inorganic impurities, and dry for later use;

[0042](2) ZnO seed crystal preparation

[0043] Weigh 3mmol of zinc chloride and 3mmol of triethanolamine, add 80mL of ethanol to make a mixed solution A, immerse the cleaned foamed nickel current collector in the mixed solution A and take it out slowly, repeat 10 times, dry it, and put it in a tube furnace , calcined at 500°C for 2 hours to obtain ZnO seed crystals;

[0044] (3) Preparation of ZnO nanoarrays:

[0045] Weigh 3mmol zinc chloride, 3mmol hexamethylenetetramine, 5g polyoxyethylene (molecular weight is 2000), add 60mL deionized water to configure mixed solution B, pour mixed solution B into the inner tank of the hydrothermal k...

Embodiment 3

[0049] A carbon cloth loaded with Fe 2 o 3 A method for preparing a porous nanowire electrode material, comprising the steps of:

[0050] (1) Arrange the hydrophilic carbon at a concentration of 2mol L -1 HNO 3 Soak in the solution for 15 minutes, then wash with deionized water to remove organic and inorganic impurities, and dry for later use;

[0051] (2) ZnO seed crystal preparation:

[0052] Weigh 1.5mmol of zinc nitrate and 1.2mmol of triethanolamine, add 50mL of ethanol to make a mixed solution A, immerse the cleaned stainless steel sheet current collector in the mixed solution A and take it out slowly, repeat 10 times, dry it, and put it in a tube furnace , calcination at 500°C for 1 h to obtain ZnO seed crystals;

[0053] (3) Preparation of ZnO nanoarrays:

[0054] Weigh 2mmol of zinc sulfate, 2mmol of hexamethylenetetramine, and 1.3g of lauryl polyoxyethylene ether, add 50mL of deionized water to configure a mixed solution B, pour the mixed solution B into the in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com