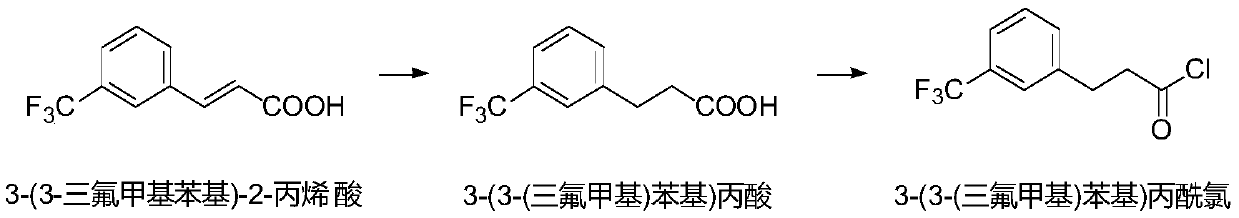

Method for synthesizing cinacalcet hydrochloride intermediate in microchannel reactor

A microchannel reactor, the technology of cinacalcet hydrochloride, is applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc. Product purity and yield, the effect of shortening the reaction residence time, reducing the chance of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

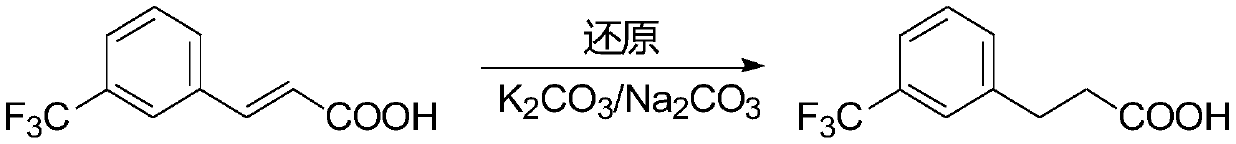

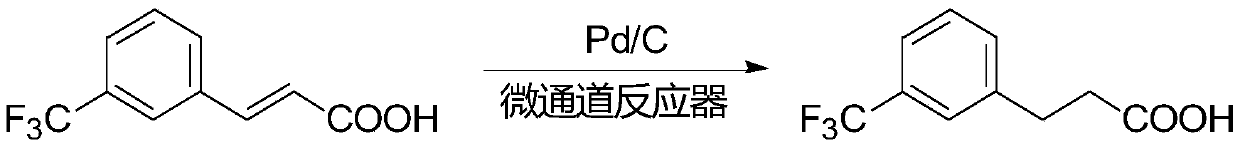

Method used

Image

Examples

Embodiment 1

[0037] Microchannel reactor 1 in this embodiment includes preheating module 1, preheating module 2, reaction module group 1 and cooling quenching module 1, preheating module 1 and preheating module 2 are arranged in parallel, preheating module 1, preheating module 1 The thermal modules two are connected in series with the reaction module group one, and the other end of the reaction module group one is connected in series with the cooling and quenching module one.

[0038] 1. Put 300g of 3-(3-trifluoromethylphenyl)-2-acrylic acid into 2L of organic solvent A, stir to form a white suspension slurry, wherein organic solvent A is toluene;

[0039] 2. Weigh 9g of palladium carbon (palladium accounts for 5% of the total mass of the catalyst), add it to the white slurry and stir thoroughly to obtain the mixture as material a;

[0040] 3. Use material pump A to transport material a to preheating module 1 at 35g / min for preheating;

[0041] 4. Control the flow meter B to transport the...

Embodiment 2

[0045] This example differs from Example 1 in that: the solvent A in Step 1 of this example is xylene, and the purity of the material in the filtered filtrate is 99.25% (GC).

Embodiment 3

[0047]The difference between this example and Example 1 is that the solvent A in step 1 of this example is tetrahydrofuran, the reaction pressure in step 5 is 1.0 Mpa, and the purity of the material in the filtered filtrate is 99.13% (GC).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com