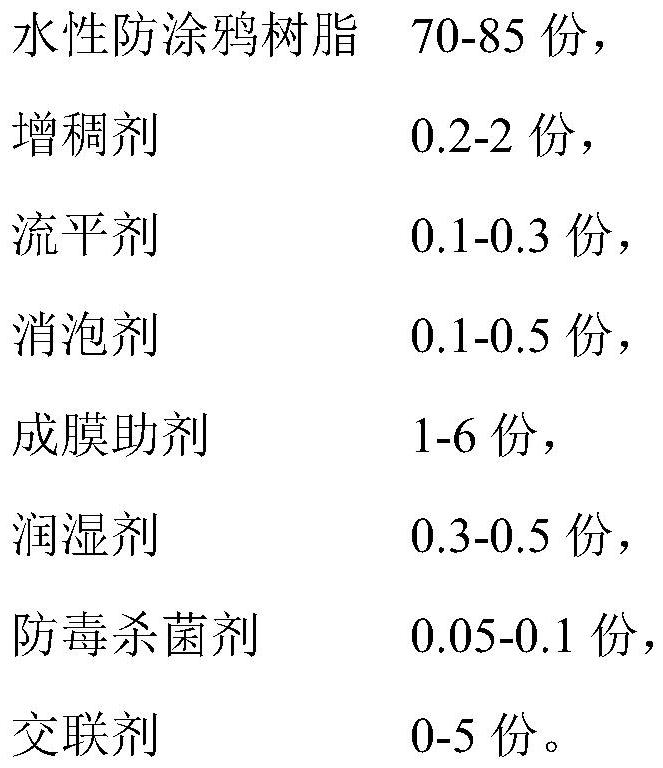

Water-based anti-graffiti resin and preparation method thereof, water-based anti-graffiti coating and preparation method thereof

An anti-graffiti resin and anti-graffiti technology, applied in the field of coatings, can solve the problems of few water-based anti-graffiti coatings, difficult construction, short open period, etc., achieve good anti-graffiti effect, recoatability, and long open period Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The preparation of embodiment 1 polyester

[0048] (1) Add 400g of adipic acid, 100g of terephthalic acid, 200g of 1,2-propanediol and 180g of 2-butyl-2-ethyl-1,3-propanediol in a reactor with a reflux condensing device. Under nitrogen atmosphere, the temperature was raised from room temperature to 120°C at a rate of 10°C / min, kept for 1.5 hours, then raised to 150°C at a rate of 5°C / min, kept for 1.5 hours, and finally raised to 180°C at a rate of 5°C / min , keep warm for 0.75 hours;

[0049] (2) Add catalyst tetraisopropyl titanate of 0.04% of the total mass of reactants into the reactor, and raise the temperature to 240°C at a rate of 10°C / 20min, reduce the pressure of the kettle to below 0.1MPa, and conduct the reaction at low pressure for 2 Hours, the polyester is obtained after discharging, the hydroxyl value of the product is measured to be 57±3mgKOH / g, and the molecular weight is 2000±100g / mol.

Embodiment 2

[0050] The preparation of embodiment 2 polyester

[0051] (1) Add 325g of succinic acid, 90g of phthalic anhydride, 237g of 1,4-butanediol and 164g of 2-n-pentylpropane-1,3-diol in a reactor with a reflux condensing device. Raise the temperature from room temperature to 120°C at a rate of 10°C / min, hold for 1.5 hours, then raise the temperature to 150°C at a rate of 5°C / min, hold for 1.5 hours, and finally raise the temperature to 180°C at a rate of 5°C / min, and hold for 0.75 hours ;

[0052] (2) Add the catalyst tetrabutyl titanate of 0.05% of the total mass of the reactants into the reaction kettle, and raise the temperature to 240°C at a rate of 10°C / 20min, reduce the pressure of the kettle to below 0.1MPa, and keep the reaction under low pressure for 3 hours. After discharging, the polyester is obtained. The measured hydroxyl value of the product is 57±3mgKOH / g, and the molecular weight is 2000±100g / mol.

Embodiment 3

[0053] The preparation of embodiment 3 polyester

[0054] (1) Add 400g of adipic acid, 100g of isophthalic acid, 200g of n-hexanediol and 150g of 2-butyl-2-ethyl-1,3-propanediol, neopentyl di Alcohol 115g, in a nitrogen atmosphere, the temperature was raised from room temperature to 120°C at a rate of 10°C / min, kept for 1.5 hours, then raised to 150°C at a rate of 5°C / min, kept for 1.5 hours, and finally heated at a rate of 5°C / min Raise the temperature to 180°C and keep it warm for 0.75 hours;

[0055] (2) Add the catalyst tetrabutyl titanate of 0.03% of the total mass of reactants into the reactor, and raise the temperature to 240°C at a rate of 10°C / 20min, reduce the pressure of the kettle to below 0.1MPa, and keep the reaction under low pressure for 2 hours. After discharging, the polyester is obtained. The measured hydroxyl value of the product is 57±3mgKOH / g, and the molecular weight is 2000±100g / mol.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com