A kind of polyurethane grouting material and its preparation method and application

A grouting material and polyurethane technology, applied in the field of grouting engineering and polymer materials, can solve the problems of cell ablation and collapse, affect the strength, and react violently, so as to increase the compressive strength and toughness, increase the compatibility, and increase the reaction. Highly active effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

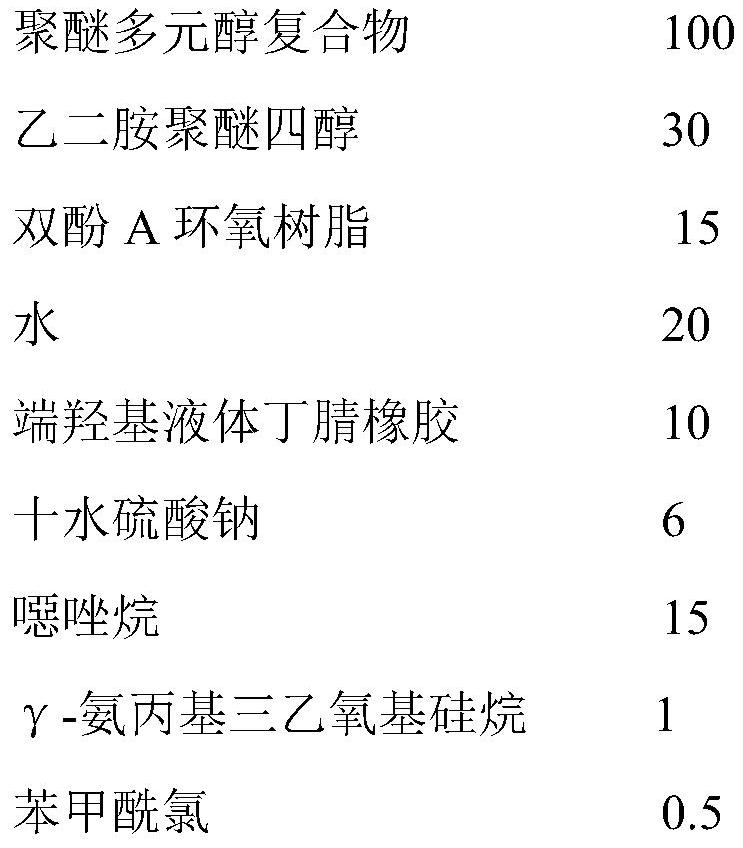

[0051] 1. Preparation of component A of polyurethane grouting material

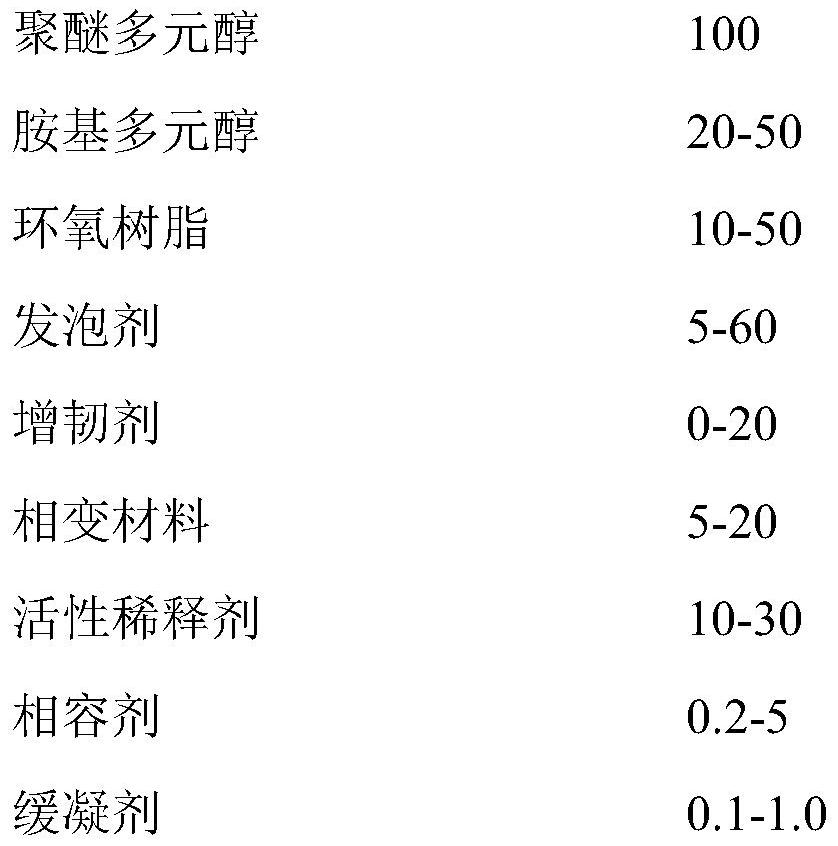

[0052] 1A), prepare component A raw materials (g) according to the following weight ratio:

[0053]

[0054] Among them: polyether polyols include propylene oxide-ethylene oxide copolyether triol and polyoxypropylene triol, wherein the functionality of propylene oxide-ethylene oxide copolyether triol is 3, the average molecular weight is 600, and the hydroxyl value is 330 mgKOH / g; The functionality of polyoxypropylene triol is 3, the average molecular weight is 3000, and the hydroxyl value is 36KOH / g; the weight ratio of propylene oxide-ethylene oxide copolyether triol to polyoxypropylene triol is 1:1, that is, propylene oxide -Ethylene oxide copolyether triol is 50g, and polyoxypropylene triol is 50g; The functionality of ethylenediamine polyether tetraol is 4, the average molecular weight is 300, and the hydroxyl value is 770mgKOH / g; Bisphenol A epoxy resin is E44; The average molecular weight of hy...

Embodiment 2

[0072] 1. Preparation of component A of polyurethane grouting material

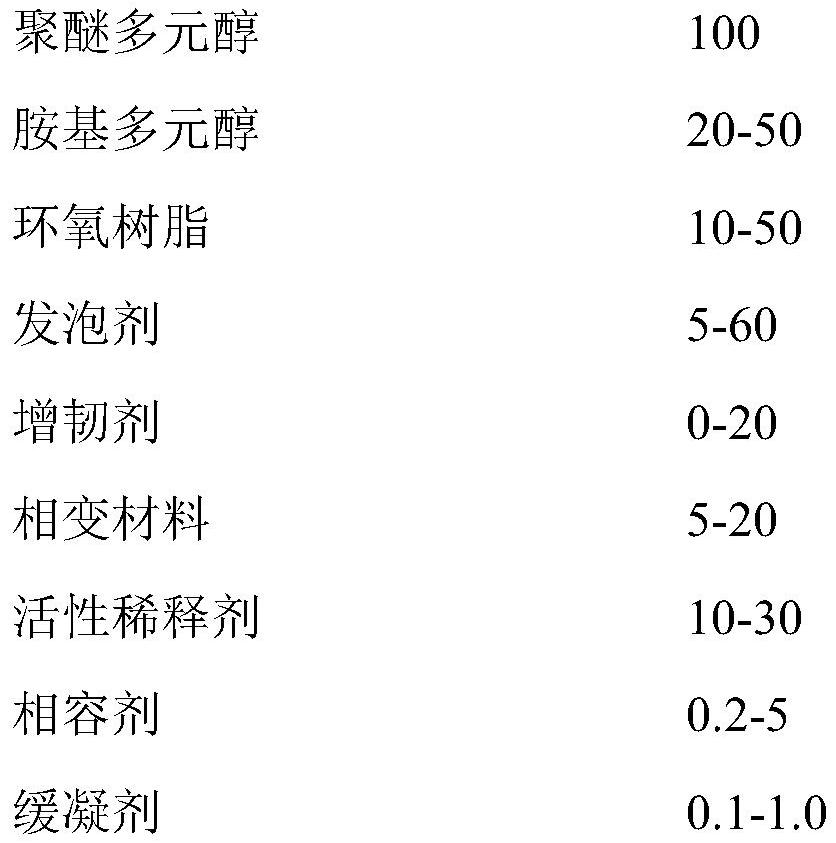

[0073] 1A), prepare component A raw materials (g) according to the following weight:

[0074]

[0075] Among them: polyether polyol includes polyoxypropylene diol and rosin ester polyol, wherein the functionality of polyoxypropylene diol is 2, the average molecular weight is 2000, and the hydroxyl value is 56; the functionality of rosin ester polyol is 3, and the average The molecular weight is 280, the hydroxyl value is 400mgKOH / g; the weight ratio of polyoxypropylene diol and rosin ester polyol is 1:1, that is, the polyoxypropylene diol is 50g, and the rosin ester polyol is 50g; toluene diamine polyether Tetrol has a functionality of 4, an average molecular weight of 600, and a hydroxyl value of 410 mgKOH / g; bisphenol F epoxy resin NPEF-170;

[0076] In this embodiment, polyoxypropylene diol and rosin ester polyol in the polyether polyol compound are mixed in a weight ratio of 1:1 as an example for ...

Embodiment 2A

[0090] 1. Preparation of component A of polyurethane grouting material

[0091] 1A), prepare component A raw materials (g) according to the following weight:

[0092]

[0093] Among them: polyether polyol is polyoxypropylene triol, wherein the functionality of polyoxypropylene triol is 3, the average molecular weight is 350, and the hydroxyl value is 500mgKOH / g; 4, the average molecular weight is 300, and the hydroxyl value is 760mgKOH / g; bisphenol S-type epoxy resin is 185s; the average molecular weight of hydroxyl-terminated liquid nitrile rubber is 3000;

[0094] Polyoxypropylene triol in the polyether polyol compound in this embodiment is illustrated as an example. In the present invention, polyether polyol can be one or multiple polyols. When multiple polyols are included, multiple polyols Alcohols can be mixed in any proportion.

[0095] Compounds mixed with polyether polyols with an average functionality of 2-8, an average molecular weight of 200-4000, and a hydrox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com