A highly filled graphene oxide/resin hybrid and its preparation method and application

A technology of graphene and hybrids, which is applied in the direction of polymer adhesive additives, non-polymer adhesive additives, coatings, etc., can solve the problem that the interfacial bonding ability cannot be improved well, and the problem of agglomeration is difficult to be effectively obtained. Solve the problems of rubber mechanical properties and processing performance, etc., to improve the ability of dispersion and interfacial bonding, easy to operate, and improve the effect of wet skid resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

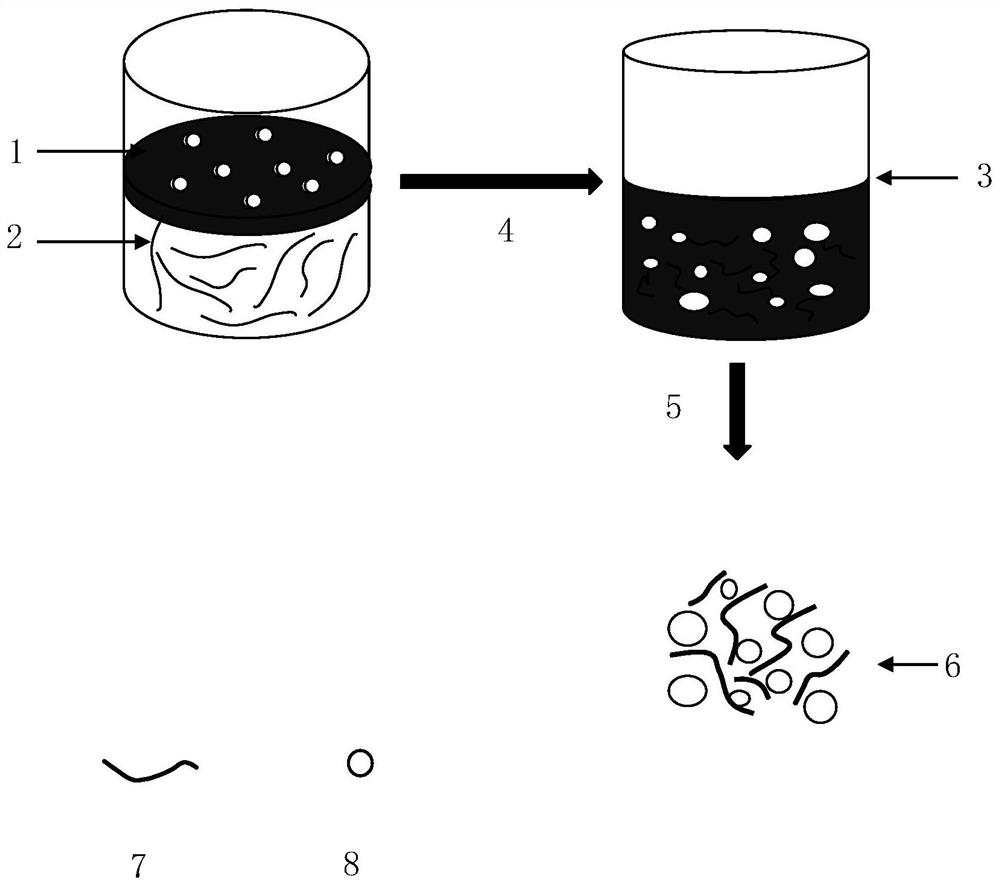

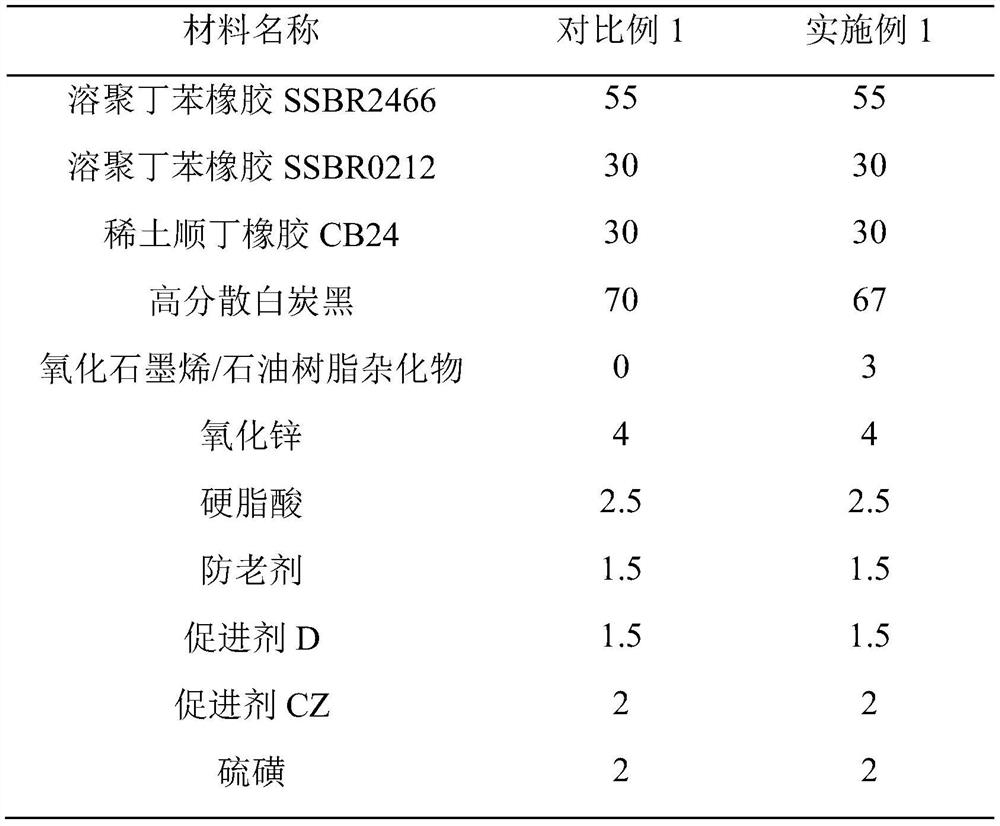

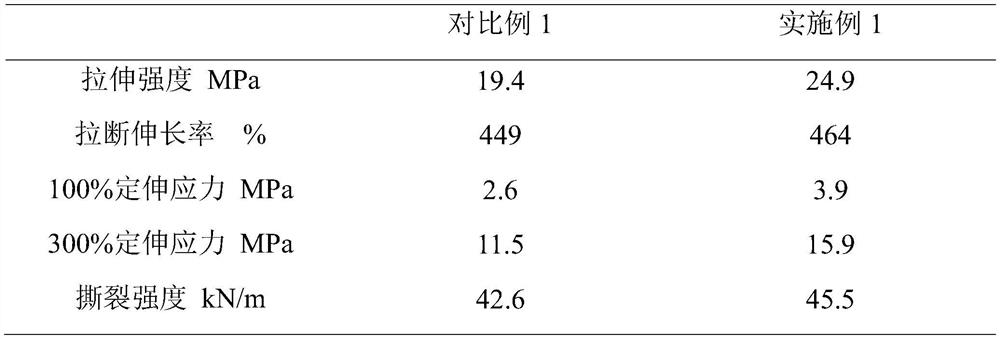

[0032] The stable and uniformly dispersed graphene oxide / petroleum resin hybrid prepared by the present invention can be used as a filler in rubber reinforcement, which can greatly improve the mechanical properties of rubber materials, and at the same time, after reduction in the later stage, the rubber can have excellent functional applications. .

[0033] (1) Weigh 5g of C5 / C9 petroleum resin, add it to 1000ml of deionized water, stir with an ultrasonic cleaner under heating at 98°C, the power is 400W, and the stirring speed is 250r / min until C5 / C9 solid petroleum resin The particles are formed into droplets, cooled to room temperature, and impurities are filtered to obtain the required petroleum resin suspension, wherein the droplet diameter of the resin suspension is 3 μm;

[0034] (2) Weigh 25 g of graphite oxide water slurry with a concentration of 2%, wherein the graphite oxide solid content is 500 mg, place it in 500 ml of deionized water, and then use a cell pulverize...

Embodiment 2

[0046] Graphene oxide, as the precursor of graphene, contains a special lamellar structure, similar to scaly mica powder, aluminum powder, glass flakes, etc. used as fillers in anti-corrosion coatings to form a tight network to achieve excellent anti-corrosion properties. The effect of corrosion.

[0047] (1) Weigh 8g of styrene resin, add it to 1000ml of deionized water, and process it with an ultrasonic oscillator under heating at 98°C. The ultrasonic power is 400W, and the stirring rate is 250r / min. Continue stirring until the styrene resin After the droplet is formed, cool to room temperature, filter the impurities to obtain the required styrene resin aqueous suspension, and the droplet diameter is 2 μm;

[0048] (2) Weigh 50 g of graphite oxide water slurry with a concentration of 2%, wherein the graphite oxide solid content is 1 g, place it in 500 ml of deionized water, and then use a cell pulverizer to perform ultrasonication with a working interval of 2 s and a power o...

Embodiment 3

[0051] Graphene oxide's unique sheet structure and a large number of oxygen-containing functional groups on the surface make it compatible with other substrates. At the same time, it has a certain degree of excellent electrical and thermal conductivity of graphene, and has also been widely used in the field of adhesives. Based on this, we consider its application in the adhesive production process.

[0052] (1) Weigh 7.5g of terpene resin, add it to 1000ml of deionized water, and process it with an ultrasonic oscillator under heating at 98°C. The ultrasonic power is 400W, the stirring rate is 250r / min, and the stirring is continued until the terpene After the resin droplets are formed, cool to room temperature, filter impurities to obtain the desired terpene resin aqueous suspension, and its size is 1.5 μm;

[0053] (2) Take by weighing 75g concentration and be 2% graphite oxide water slurry, wherein graphite oxide solid content is 1.5g, it is placed in the deionized water of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com