Composite diaphragm and preparation method and use thereof

A composite diaphragm and base film technology, applied in electrical components, circuits, battery pack components, etc., can solve the problems of large particle size of LLZO, improved battery performance, complicated preparation process, etc. The effect of improved performance and improved cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0089] A kind of preparation method of composite diaphragm comprises the steps:

[0090] (1) Take CuSAPO-5 molecular sieve with a size of 4 μm, sulfonated melamine formaldehyde condensate (German BASF company, F10 brand) and water to prepare a coating dispersion through 3000r / min high-speed sand milling for 3.5h, wherein CuSAPO-5 The mass ratio of molecular sieve and sulfonated melamine formaldehyde condensate is 3:1, then the coating dispersion liquid, acrylate binder and polyether modified polydimethylsilane wetting agent are stirred at room temperature Prepare a coating coating solution, the content of the acrylate binder in the coating coating solution is 0.8 wt%, and the content of the polyether-modified polydimethylsilane wetting agent is 0.05 wt%;

[0091] (2) Choose a polyethylene (PE) diaphragm with a thickness of 9 μm, and dip it in the coating solution for dipping and pulling coating (lifting rising speed: 60mm / min; falling speed: 100mm / min; dipping time: After 1 m...

Embodiment 2

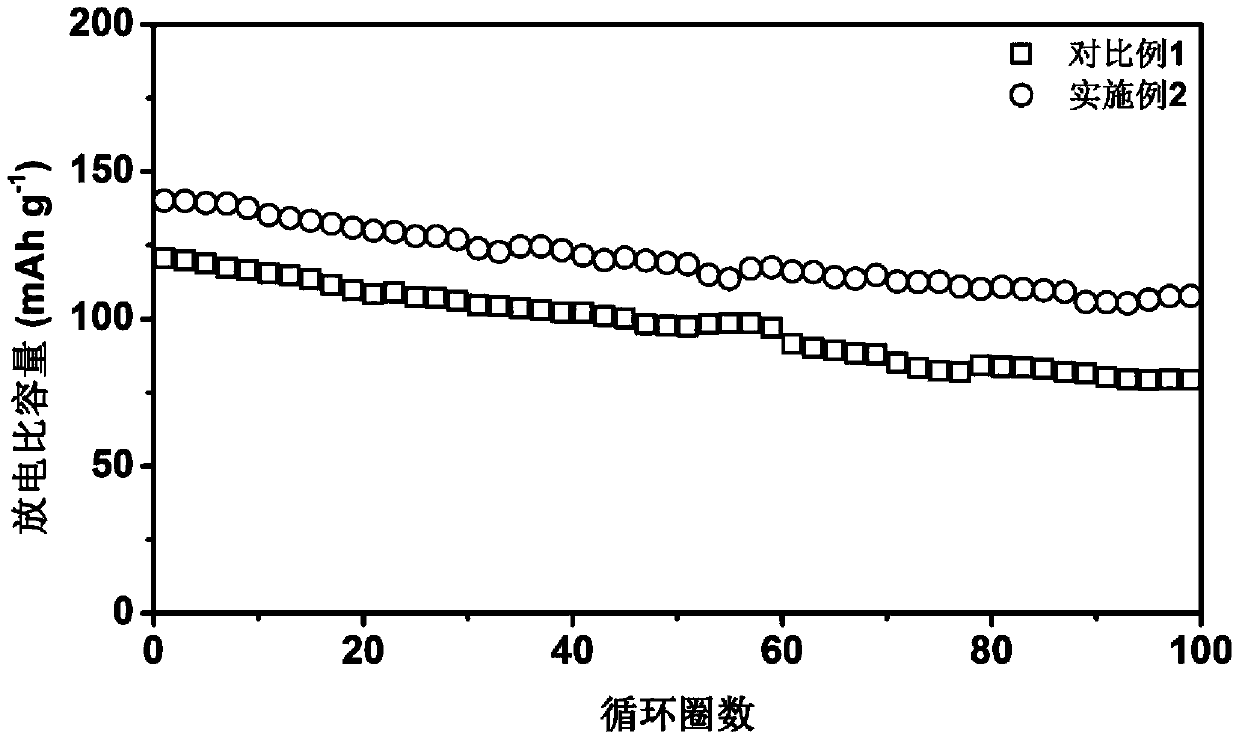

[0093] The difference with Example 1 is that the mass ratio of molecular sieve and sulfonated melamine formaldehyde condensate (BASF, Germany, F10 brand) described in step (1) is 2:2, and in the prepared composite diaphragm, the selective control coating The morphology is a stacked structure composed of granular and flake materials. Figure 4 This is the SEM image of the stacked structure described in this example. It can be seen from the figure that the selective control coating in the composite diaphragm presents a disordered stacked structure of inorganic components composed of granular and sheet-like materials.

Embodiment 3

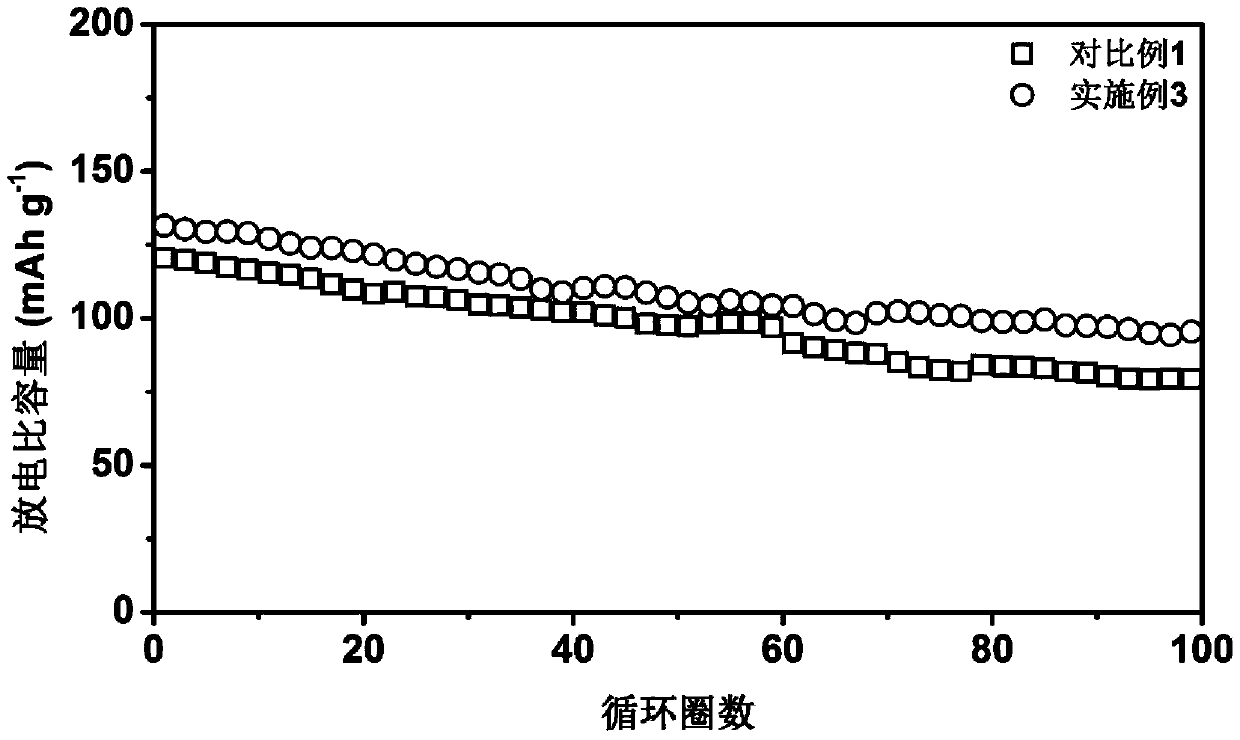

[0095] The difference with Example 1 is that the mass ratio of molecular sieve and sulfonated melamine formaldehyde condensate (BASF, Germany, F10 brand) described in step (1) is 1:3, and in the prepared composite diaphragm, the selective control coating The morphology is a disordered stacking structure of granular and flake inorganic components.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com