Oxygen storage material and its manufacturing method

An oxygen storage material and technology for manufacturing methods, applied in chemical instruments and methods, catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, etc., to achieve excellent oxygen evolution rate, inhibition of thermal decomposition, heat resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

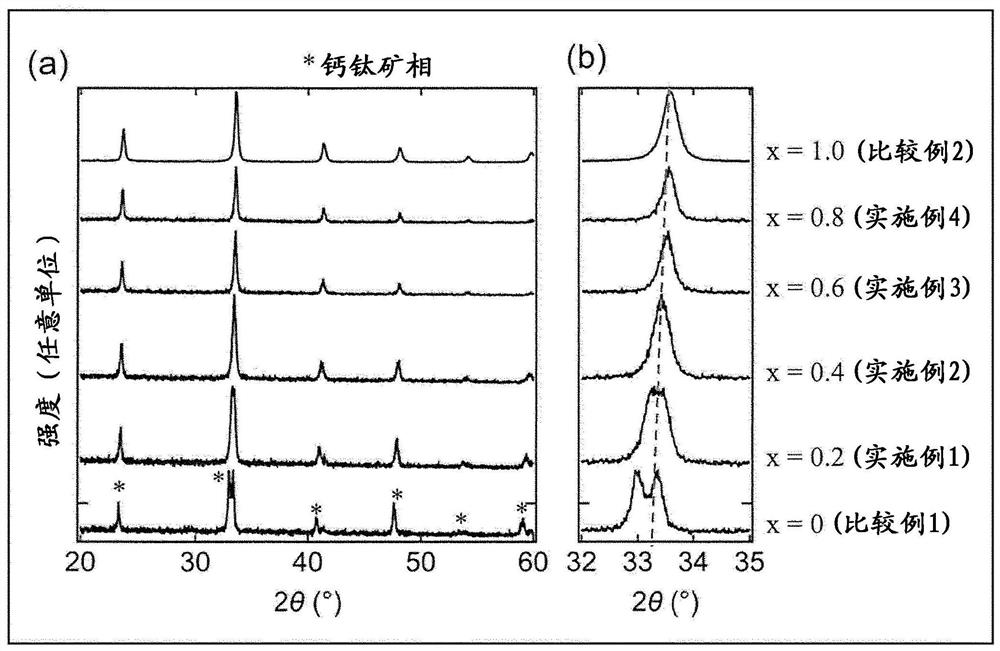

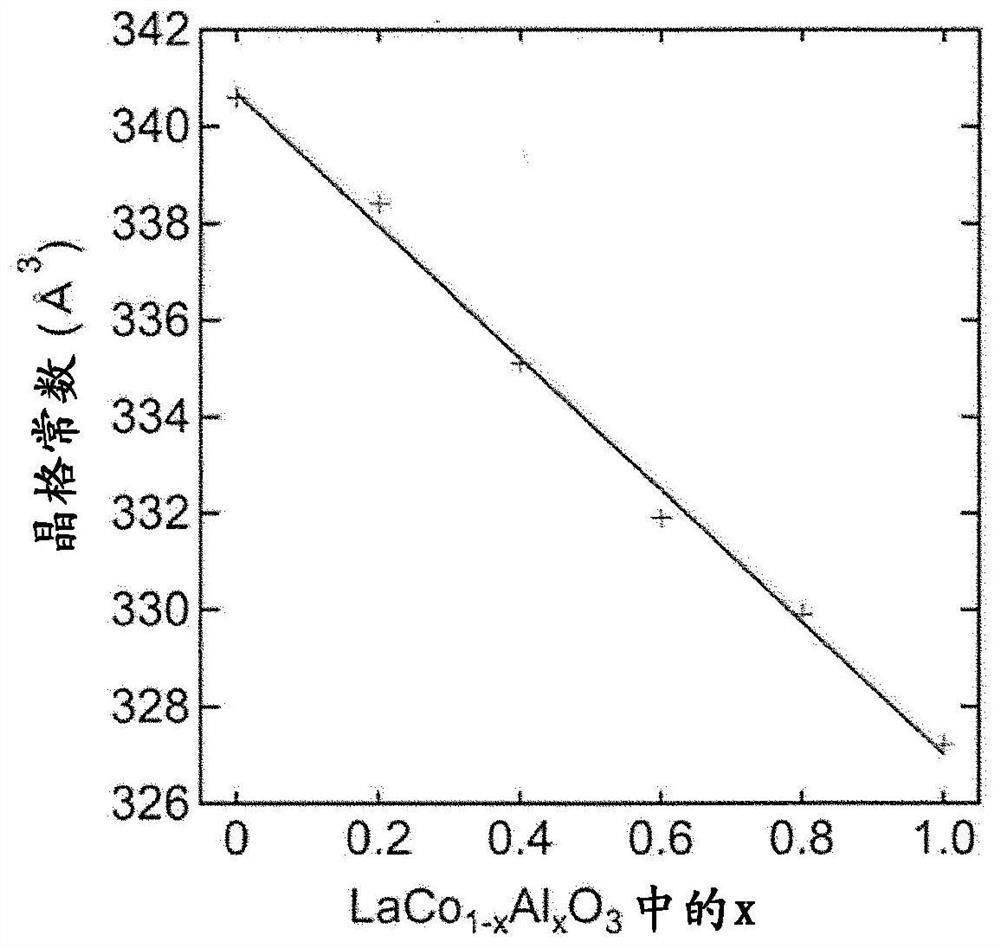

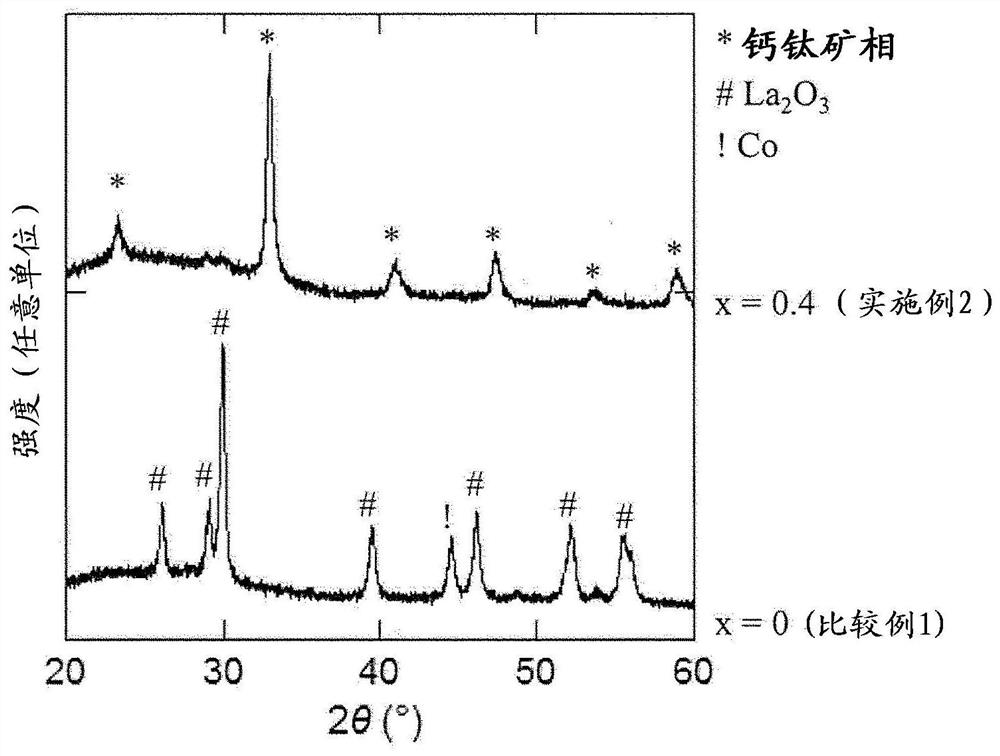

[0080] Set the target composition to LaCo 0.8 Al 0.2 O 3 (Composition: LaCo 1-x Al x O 3 where x=0.2), the La-Co-Al composite oxide having the above-mentioned composition was obtained by the complex polymerization method as described below.

[0081] That is, first, lanthanum nitrate, cobalt nitrate, and aluminum nitrate in stoichiometric ratios were dissolved in the minimum amount of pure water shown in Table 1 at the input amounts shown in Table 1 at room temperature, In order to make it the above target composition, after confirming that the solution became transparent, citric acid in the amount shown in Table 1 and ethylene glycol in the amount shown in Table 1 were added to the total amount of cations. Dissolve and mix to obtain a solution containing the metal citric acid complex. Next, the solution containing the above-mentioned metal citric acid complex was heated to 150° C. and maintained for 30 minutes to obtain a polymer gel in which the above-mentioned metal ci...

Embodiment 2~4

[0083] In addition to setting the target composition as

Embodiment 2

[0084] Example 2: LaCo 0.6 Al 0.4 O 3 (Composition: LaCo 1-x Al x O 3 in x=0.4)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com