Jet 3D printing functional gradient electromagnetic protective material and preparation method thereof

A 3D printing, electromagnetic protection technology, applied in the direction of manufacturing tools, additive processing, ceramic molding machines, etc., can solve the problems of reduced material mechanics and structural properties, cumbersome construction steps, easy to fall off, etc., to overcome the short coagulation time, The effect of excellent electromagnetic protection effect and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

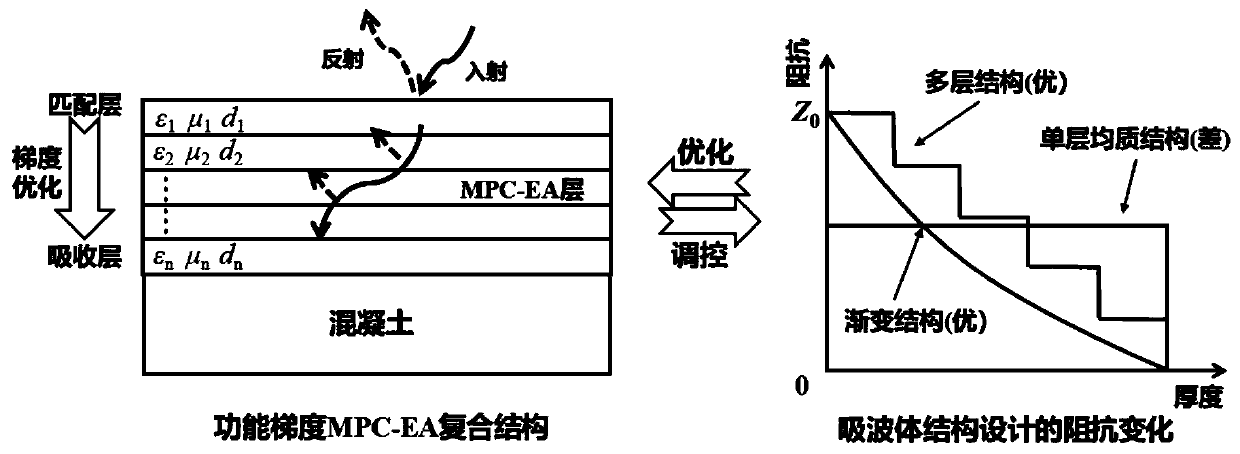

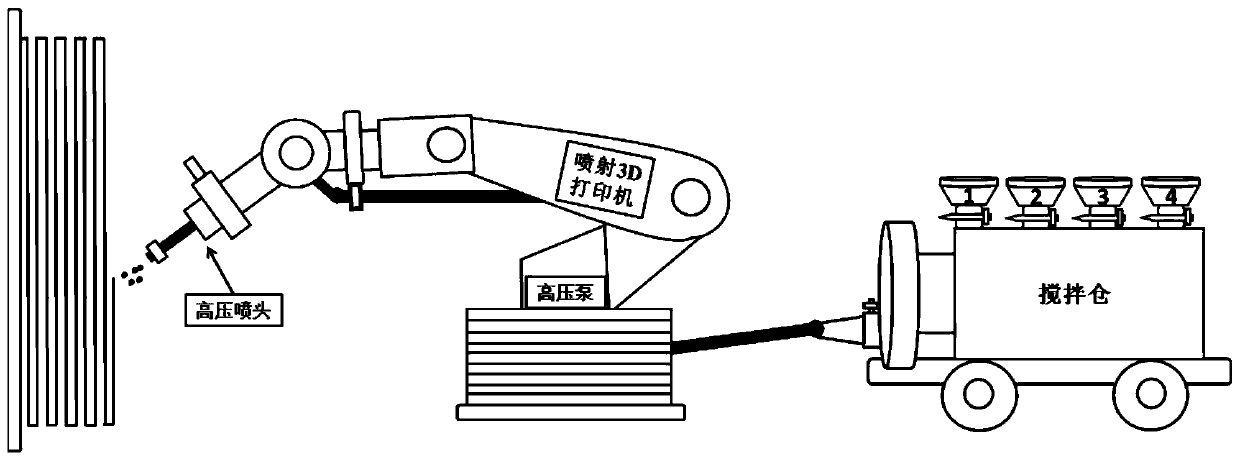

Method used

Image

Examples

Embodiment

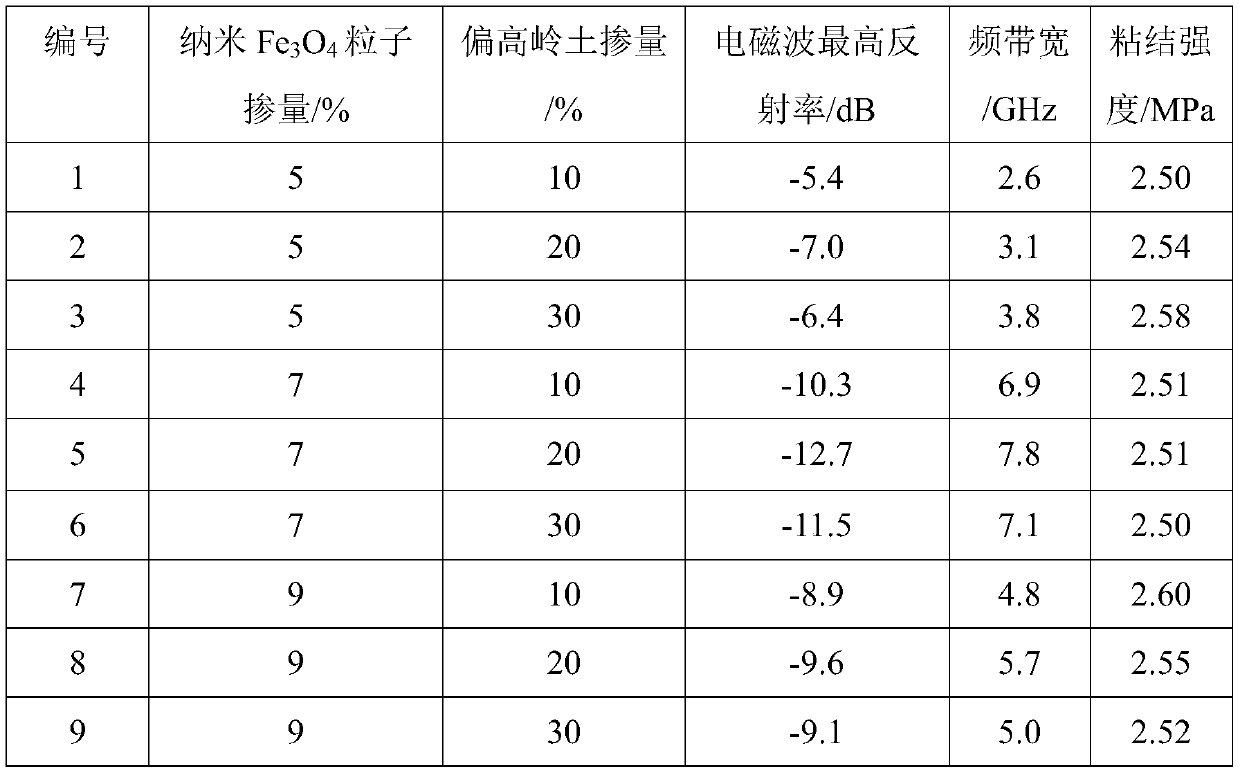

[0045] According to nano Fe 3 o 4 Particle dosage divided the experiments into three groups. In all tests, the dosage of water reducing agent is selected as 4% of the water mass, the dosage of borax is 5% of the mass fraction of MgO, the thickness of the wave-absorbing layer is 15mm, and the impedance gradient difference is determined by the dosage of shale ceramsite. Arithmetic distribution: According to the content of shale ceramsite (accounting for the volume fraction of MgO in this layer) is 10%, 20%, 30%, 40%, and 50%, respectively, it is divided into five kinds of wave-absorbing layers with gradual impedance changes, according to The distance close to the concrete matrix is set from near to far;

[0046] Group 1 contains a wave-absorbing layer, and its shale ceramsite content in cement is 30%, and the data and implementation methods in Table 1 of the remaining components are given in accordance with the above-mentioned preparation method;

[0047] Group 2 contains t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Adhesive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com